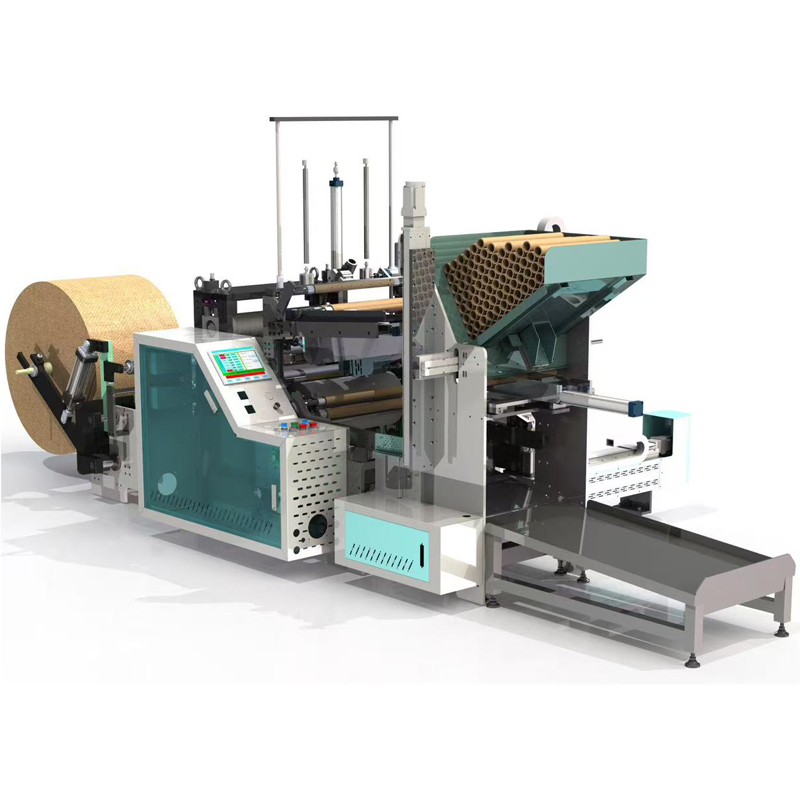

Single Layer Kraft Paper Mailer Machine

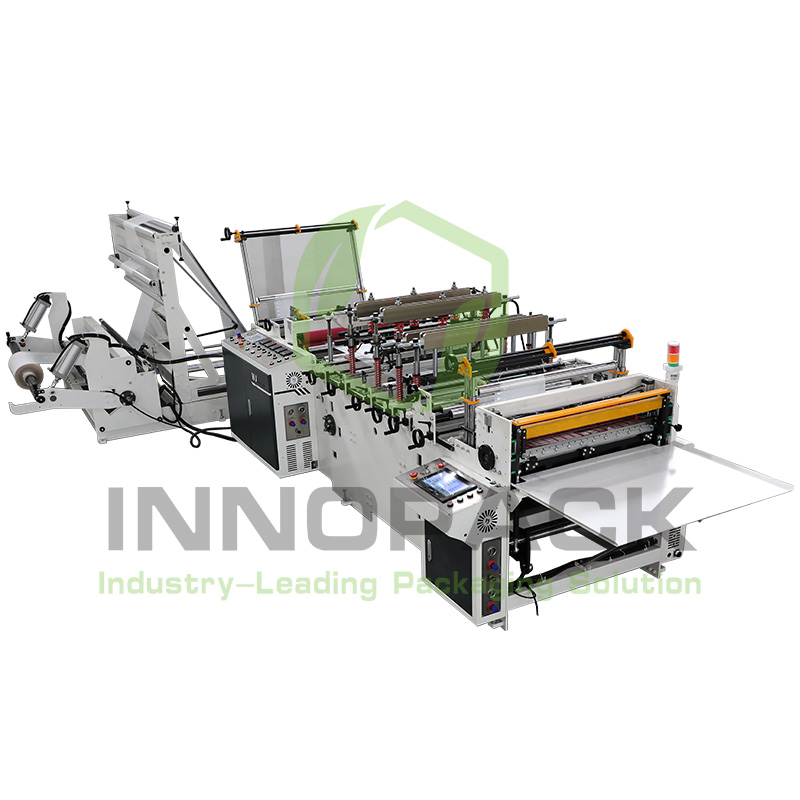

INNO-PCL-1000

The Single Layer Kraft Paper Mailer Machine by Innopack is an advanced automated system for producing eco-friendly, tear-resistant kraft paper mailers at high speed. Featuring PLC control, servo motor precision, and integrated unwinding, embossing, slitting, folding, sealing, and adhesive application, it delivers lightweight, customizable, and recyclable mailers. Designed for e-commerce, logistics, and express delivery, it reduces shipping costs, boosts productivity, and meets sustainable packaging demands.

Model

INNO-PCL-1000

Material

Kraft Paper

Speed

40–80 bags/min

Width Range

≤1600 mm

Control

PLC + Servo Motor + Touch Screen

Application

Paper mailer production for e-commerce and logistics