Tshawb nrhiav vim li cas Xa Ntawv Machine Overperform phau ntawv ntim hauv 2025, ua ke ua ke, precision seuess, thiab sustainability. Tshawb nrhiav nrawm, durability, esg ua raws cai, thiab roi zoo backed los ntawm cov kws tshaj lij kev nkag siab, cov ntaub ntawv kev pom tseeb tiag tiag, thiab niaj hnub logistics tshiab.

Cov ntsiab lus ceev ceev: "Lub caij nyoog ceev tau nyob ntawm no-rov qab yog nce toj thiab cov suab yog stricter," The Roo hais nyob rau DC Catwalk.

Ceev tsis muaj kev xav tsis thoob : "Yog tias peb siv tsheb, peb puas poob hloov tau?"Kws ua choj: "Peb tau txais kev rov ua haujlwm dua. Xa Ntawv Machine Kov Kraft, iav, thiab txheej txheej uas xav tau-nrog cov lus tsa suab, thiab cov koob yees duab uas txheeb xyuas txhua txoj leeg. Cov neeg ua haujlwm xaiv; tshuab pob nrog precision. Phau ntawv kab khiav mus rau khib, oversized, lossis promo cov khoom siv. "

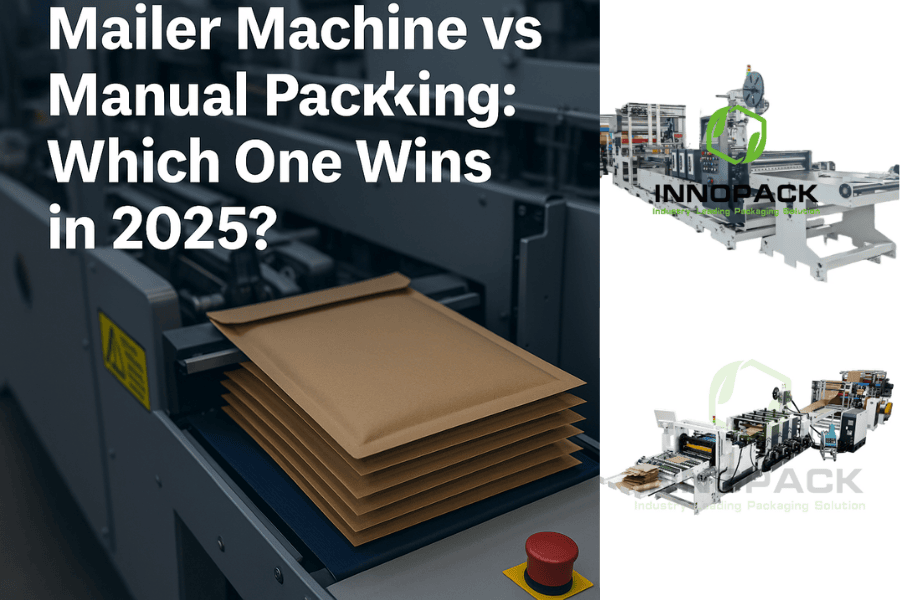

Tus neeg xa xov siv lub tshuab vs kev tuav ntaub ntawv Kev ua Tus xa khoom tshuab Kev Tuav Cov Lus Kev Tawm Tsam & TAKT Lub siab ruaj khov RPM; 1-2 tus neeg ua haujlwm nyob rau hauv lub cell Kuj sib txawv; Nyob ntawm kev ua haujlwm thiab nkees Zoo & durability Servo quav, tas mus li Dwell & Nip; Cov kab hauv lub zeem muag tiv thaiv cov ceg tawv tsis muaj zog Tib neeg kev hloov siab; muab lub zog muaj peev xwm tuaj yeem txav mus rau kev hloov pauv Kuaj Npaj Nws Pib Batch cav (Rhaub profiles, QC cov duab, ntau taug qab) Cov ntawv sau; nyuaj rau kev sib haum xeeb, qeeb qeeb Dim & freight Haum sib xws; Tsawg dua lub sijhawm; Txhim Kho Xa Ntawv Geometry Nyhav rau ntau dua; ntau dua dim outliers Khib & Rov Ua Haujlwm Daim ntawv qhia-tswj; qis trim poob thiab rov ua haujlwm Siab dua cov ntsaws ruaj ruaj, cov nplais nkhaus, rov ua dua Kev Kawm & Cov Neeg Ua Haujlwm Tus neeg teb xov tooj-HMON; Kev cob qhia dua Nruam kev txawj li Drilling; siab dua tus nqi Kev loj Ntxiv cov cells, theej zaub mov txawv; Xuas tau oee Tes tshiab ≠ Cov Khoom Zoo; Kev Kawm Hluas Nkauj Nkhaus Zoo tshaj plaws haum Cov ciav hlau khiav ceev nrog kev twv seb puas muaj kev sib tw loj Khib, bulky, cov khoom siv caij nyoog; Me-batch promos

Lag Luam Wholesale Tus Kws Xa Ntawv Tshuab

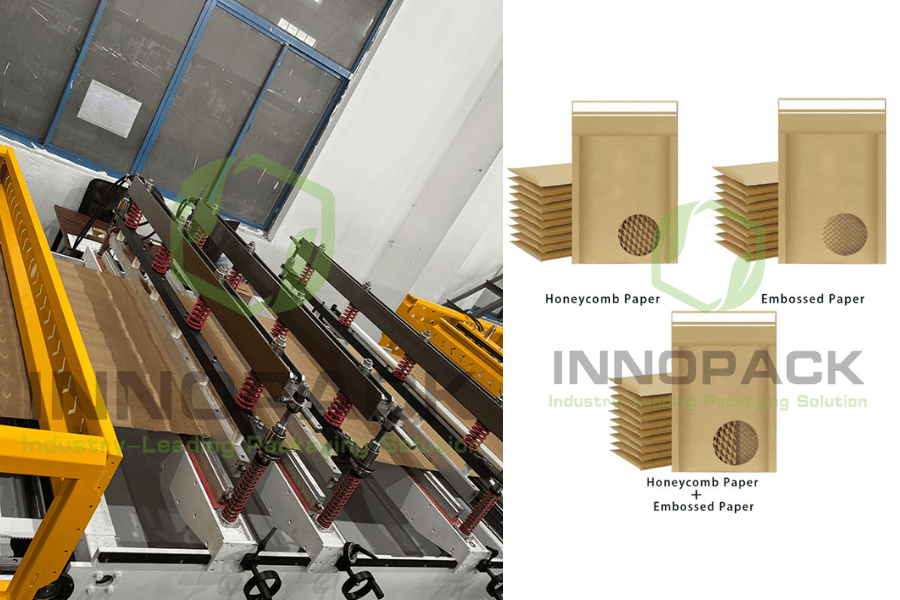

Peb Lub Tshuab Xa Ntawv (1/2): Khoom, tsim, thiab "vim li cas nws zoo dua" Cov ntaub ntawv peb ua kom zoo rau Kraft (60-160 GSM) : High tensile, khawm lub cim xeeb, luam tawm rau cov cim / branding.

Iav : translucent, ntom, Hwm zoo; du nto rau daim ntawv sau tseg.

Cov ntawv txheej (dej-raws) : Vaum arteration thaum tuav rov ua dua tshiab.

Poly Xa Ntawv (qhov uas xav tau) : thin-gauge films nrog anti-static qub / plam ntxiv cov kev sib ntxiv rau cov kev coj ua thiab cov dej noo rhiab.

NEEG KHO TSHUAB & TSAV TXIV NWM Tag nrho cov-servo suab Rau cov ntawv cim khi, gussets, thiab flap tso (± 0.1-0.2 mm).

Kaw-voj nro Nyob thoob plaws Unwind / Tsis Taus kom tsis txhob muaj micro-wrinkles.

Kev yoog kev sib khi Nrog PID cia nyob rau hauv, nip, thiab kub nyob rau hauv lub Windows loj.

Nyob rau hauv-line lub zeem muag checks Seam Geometry, Muab cov nplaum muaj, thiab quav qhov tseeb; Ai chij drift thaum ntxov.

Tus neeg teb xov tooj-First Hmi : Daim ntawv qhia cov tsev qiv ntawv, cov chaw khaws ntaub ntawv hloov chaw, SPC dashboard, lub cav kev tshwm sim.

Vim li cas nws outperforms "dog dig" Durability los ntawm kev tsim qauv : zoo sib xws raug foob lub zog txo kev ua tsis tiav.

Paib nce : Optimized zes thiab riam txoj kev txiav txiav tsis muaj kev txiav caj dab thaum 2-5%.

Oee Ruaj : Kev sib tw txij nkawm ntawm bearings, drive, thiab cua sov drives

Zog Efficiency : Tsawg-tshav se khi thaiv cov blocks thiab ntse ntsuav txo kwh / 1,000 units.

Peb lub tshuab xa ntawv (2/2): Txheej Txheem, QA, kev ntseeg tau Txheem Ntau Lawm Ntus Cov Khoom Siv IQ : Txheeb xyuas GSM, MD / CD TENENILE, Hahleature, lub zog hnyav.

Daim ntawv qhia lub xauv-hauv : Siv tau cov rhaub qhov rais, kua nplaum grams / m², cov hom phiaj nip thiab nyob hauv.

Tsav kev ntxhov siab : Simulate viav vias / Kub viav vias thiab kev co profiles.

Oee baseline : Ceev / muaj / muaj kev sib tw zoo nyob rau hauv lub sijhawm tiag tiag.

Tshuaj Xyuas : Batch ID, Rhaub profiles, QC cov duab, ntau-rau-pallet daim duab.

QC & Kev Ntsuas Kev Ua Haujlwm SEAM PAJ TSAUB : ≥3.5-5.0 n / 25 hli (chav kawm-kawm).

Nrov / Ntug Mos : Raws li SKU-SPACT-SPUS.

Daim ntawv lo nyeem cov nqi (Qhov rai iav): ≥99.5% scan yog.

Qhov seem tsis ntev : ± 0.2 mm ntawm cov quav tseem ceeb; ± 0.3 hli trims.

Khiav-rau-khiav CPK : ≥1.33 ntawm qhov ntev tshaj plaws nyob thoob plaws 8 teev teev.

Tus Neeg Teb Xov Tooj Kev Kawm & Kev Nyab Xeeb 8-12 min Daim ntawv qhia kev hloov pauv; Auto-xov & Cov Tooling Quine.

Hmi Nrog cov ntoo txhaum thiab lub koob yees duab snippets rau kev daws teeb meem sai sai.

Kev xyuas xim : Cat-3 Circuits, Cov kab hlau lub teeb, stlockocks, e-nres (en / ul).

Cov Ntaub Ntawv Ua Lag Luam: Vim Li Cas Xa Ntawv Machine yeej Nce cov khoom muaj nqis Cov ntaub ntawv-logged kev ua tau zoo txhawb kev tshuaj ntsuam cov kev soj ntsuam thiab tus nqi resale.

Cov zaub mov txawv txawv ua ntau lub vev xaib rov ua dua tshiab-ib qho cuab tam muaj rau kev sib koom tes DCS.

Durability nyob rau hauv daim teb Kev sib sau ua ke thiab khawm geometry txhais tau txhais tau tias tsawg dua seam ua tsis tiav.

Zoo dua Txoj kev resilience -Machines khaws cov khoom tawm hauv cov kev hloov pauv txawm tias muaj kev hloov hauv qab.

Opex & kev thauj khoom Kev kho zuj zus : Txoj cai rau-loj me me txo qis nqi volumetric.

Rook & Rov Los : Tsawg dua ua tsaug rau cov leeg ncaj ncees thiab kev tswj daim ntawv qhia.

Lub zog : Txo cov ntsiab lus kaw, ua tau zoo cov khoom cua kub.

Cov Kws Muaj Peev Xwm (2023-2025) Lin, Lin, Ntim Ntim (2024): "Cov kab ntawv xa tawm yog tus txha caj qaum ntawm High-Kev Lag Luam. Kev nqa khoom ntxov ua ntej kaw hauv kev ua raws fab thiab nqa hom khoom."

Dr. Emily Carter, MIT Cov Ntaub Ntawv Chav (2023): "Servo-txheej txheem Kraft / iav Seams ua tiav qhov ntsuas hluav taws xob piv rau ntau lub polymer mailers hauv cov yeeb yaj kiab thiab kev sim ua kom tawg."

PMMI Kev Tshaj Qhia Kev Lag Luam (2024): "Ntim khoom siv rau kaum-nphom chaw pib thiab cov ntawv ceev-txheej poly yog ob qho tib si outpacing txhais tes sib xws."

Cov ntaub ntawv tshawb fawb koj tuaj yeem ntseeg tau Cov neeg siv khoom nyiam : EU Kev Tshawb Xyuas (~ 2023) Qhia ~ 85% nyiam ntim khoom siv tau; ~ 62% kev txuas cov ntawv xa mus rau cov hom hwm hwm.

Khoo Nti Qhov Kev Muaj Tiag : Ntim / ntim txhuas tag nrho cov khib nyiab; Daim ntawv recycling tus nqi feem ntau > 68% Hauv kev tsim cov lag luam (2024 cov ntaub ntawv).

Logistics cuam tshuam : Xa Ntawv Txoj Cai-Sizing thiab Zoo Li Sealing Txo Kev Dim them txog ~ 14% Hauv kev tswj hwm kev sim (mus kom ruaj ruaj logistics, 2023).

Kev cuam tshuam kom txo : Lub Zeem Muag-Pab cov kev txiav tawm ntawm cov khoom tsis xws luag 20-30% Piv nrog siv cov tshev (muaj tshuab kos, 2024).

Padded coter ua tshuab

Peb Ua Haujlwm Snapshots E-Lag Luam Appar (Cov Ntawv Mailers rau ntawm lub tshuab) Nkaus: Hloov los ntawm kev tuav poly rau Caw Kaw Lus Kraft / iav Moters .Qhov tshwm sim: 12-15% kev txuag nyiaj , scuff-cuam tshuam rov qab los ~ 18% , Sai Sai.

Phau Ntawv & Media (Imine Windows + Lub Zeem Muag Qa) Nkaus: Nws pib cov ntawv cim tom qab iav iav; koob yees duab txheeb ze.Qhov tshwm sim: 99.5% scan yog , tsawg dua cov lus tsis zoo, nqus tsev ntxhua khaub ncaws ua si.

Electronics Accessories (Hybrid Portfolio) Nkaus: Cov ntawv xa ntawv rau cov kab ke ruaj khov; Poly Xa Ntawv Rau cov dej noo-rhiab lossis ntse-ntug skus.Qhov tshwm sim: Zero-kev puas tsuaj rau Alpusile Skus, ESG zaj dab neeg lawm, tsawg dua kev thauj khoom.

Tus Neeg Siv Tswv Yim "Daim ntawv qhia kev hloov pauv hauv feeb-peb cov nqi rov ua haujlwm." - Cov Haujlwm Tsim Haujlwm

"Batch cav nrog rhaub profiles thiab QC cov duab txiav kev tshawb xyuas lub sijhawm nyob hauv ib nrab." - Ua raws li

"Tus kab txheem kab txheem ntawm cov tshuab, khib phau ntawv-uas Hybrid phiaj xwm thaum kawg tau xaus ntim ua yeeb yam tas li." - Tus tswj hwm Logistics

Tus neeg xa khoom tshuab tsum

Cov FAQ Yog a Tus xa khoom tshuab

Ib lub tshuab puas tuaj yeem khiav ob qho tib si Kraft thiab iav?

Dab tsi yog lub roi? 6-18 lub hlis , tsav los ntawm qis tus nqi puas tsuaj, tsawg dua kev ua haujlwm, cov khoom noj khoom haus khoom muag, thiab xyuas nrawm dua.

Yuav automation ua rau mob hloov pauv? Kev qhia me me txoj kab rau khib khib thiab promos; automate tus so rau kev twv ceev thiab ua tau zoo.

Yuav ua li cas peb thiaj li siv tau kev pab them nyiaj?

Ntawv Sawv cev Lin - Automation & Coster Cov Qauv Hauv High-Kev Lag Luam E-Kev Lag Luam , Ntim Ntim Yav Tom Ntej, 2024.

Emily Carter, PhD - Durability ntawm kraft / khob cij seams raws li servo tswj Cov ntaub ntawv AIT, 2023.

PMMI - Kev Ntim Ntiaj Teb Ntim Machinery Ua Lag Luam Outlook 2024 .

EPA - Ntim & Ntim: Ntau tiam, rov qab siv & rov qab , 2024.

Phau ntawv Journal ntawm Sustainable Logistics - Dim txuag los ntawm cov ntawv loj-loj , 2023.

Ntim Europe Saib xyuas - Hybrid Portfolios: Cov Ntawv Mackers + Poly rau Kev Pheej Phuam , 2024.

Phau ntawv Journal ntawm kev muaj tshuab kos - Zeem muag-pab sib khi thiab tshem tawm qhov tsis zoo , 2024.

Muaj kev tsim khoom lag luam kev lag luam - Lub zog ua kom zoo nyob rau hauv kev hloov cov kab , 2024.

Cov Ntawv Qhia Thoob Ntiaj Teb - Kev sib xyaw ua lag luam DC automation , 2024.

InnopackMachinery Tus xa kab kab sealing Windows & OEE Playbook , 2025.

Dr. Emily Carter los ntawm MIT cov ntaub ntawv cov khoom siv hauv chav kuaj cov khoom siv tau ua tiav qhov kev ntsuas, ua raws li kev kuaj xyuas niaj hnub. " Ib yam li ntawd, ntim cov kws khaws cia Sarah Lin sau ntawv qhia txog cov kab ke thiab cov khoom siv hluav taws xob nce qib thiab cov khoom siv Lawv cov kev tso duab ua ntej, kev hloov kho tau zoo, thiab cov ntaub ntawv rov qab tsim kho kom haum rau kev sib tw, kev ntseeg siab tsis tau, thiab ib puag ncig muaj peev xwm. Kev lag luam tau nkag mus rau ib lub hnub nyoog uas ntim tsis yog tus nqi nkaus xwb - nws yog ib qho khoom siv nrov.