ស្វែងយល់ពីរបៀបដែលម៉ាស៊ីនផលិតខ្នើយខ្យល់ Paper កំពុងកំណត់ឡើងវិញនូវភស្តុភារពណ៌បៃតងជាមួយនឹងវត្ថុធាតុដើមដែលអាចកែច្នៃឡើងវិញបាន ស្រោមខ្នើយជាប់បានយូរ និងការសន្សំសំចៃថ្លៃដើម។ ស្វែងយល់ពីការច្នៃប្រឌិតចុងក្រោយបង្អស់ដែលធ្វើអោយប្រសើរឡើងនូវប្រសិទ្ធភាព និរន្តរភាព និងការអនុលោមតាមប្រតិបត្តិការវេចខ្ចប់ទំនើប។

សេចក្តីសង្ខេបខ្លីៗ៖ ម៉ាស៊ីនផលិតខ្នើយខ្យល់ក្រដាសកំពុងធ្វើបដិវត្តភស្តុភារទំនើបដោយផ្តល់នូវខ្នើយដែលអាចកែច្នៃឡើងវិញបាន និងសន្សំសំចៃបាន ដែលប្រកួតប្រជែងនឹងប្រព័ន្ធប្លាស្ទិកបែបប្រពៃណី។ ជាមួយនឹងការកើនឡើងនៃបទប្បញ្ញត្តិបរិស្ថាន ម៉ាកយីហោកំពុងងាកទៅរកការវេចខ្ចប់ខ្យល់ដែលផ្អែកលើក្រដាសសម្រាប់អត្ថប្រយោជន៍ និរន្តរភាព ភាពធន់ និងអនុលោមភាពរបស់វា។ អត្ថបទនេះស្វែងយល់ពីរបៀបដែលម៉ាស៊ីនទាំងនេះបង្កើនប្រសិទ្ធភាពប្រតិបត្តិការ កែលម្អ ROI និងកំណត់ទីតាំងក្រុមហ៊ុនផលិតសម្រាប់អនាគតដ៏បៃតង និងប្រកួតប្រជែងជាងមុន។

ការសន្ទនាពីជាន់ឃ្លាំង

“តើយើងពិតជាអាចប្រើប្រាស់ប្លាស្ទីកដោយមិនបន្ថយការផលិតបានទេ?”

នោះហើយជាសំណួរដែលអ្នកគ្រប់គ្រងផ្នែកដឹកជញ្ជូនបានសួរ ខណៈពេលកំពុងមើលការវិលជុំនៃក្រដាស kraft យ៉ាងរលូនទៅក្នុងម៉ាស៊ីនផលិតខ្នើយខ្យល់ថ្មីមួយ។ ក្រុមវេចខ្ចប់របស់គាត់បានជួបការលំបាកជាមួយនឹងថ្លៃដឹកជញ្ជូនខ្ពស់ និងការត្រួតពិនិត្យនិរន្តរភាព។ ក្នុងរយៈពេលប៉ុន្មានសប្តាហ៍នៃការប្តូរ ពួកគេបានរាយការណ៍ពីការដឹកជញ្ជូនដែលខូចតិចជាងមុន ដំណើរការលឿនជាងមុន និងឯកសារកែច្នៃឡើងវិញកាន់តែងាយស្រួល។

ការផ្លាស់ប្តូរនេះមិនមែនជានិន្នាការទេ វាគឺជាការផ្លាស់ប្តូរយុទ្ធសាស្ត្រ។ នៅទូទាំងឧស្សាហកម្ម និរន្តរភាពមិនមែនជាជម្រើសទៀតទេ។ ក្រុមហ៊ុននានាកំពុងផ្លាស់ប្តូរយ៉ាងសកម្មនូវផ្លាស្ទិចដែលប្រើតែមួយដង ខ្នើយខ្យល់ដែលមានមូលដ្ឋានលើក្រដាសធ្វើឱ្យមានតុល្យភាពនៃការអនុវត្តជាមួយនឹងការច្នៃប្រឌិតដែលមិនប៉ះពាល់ដល់បរិស្ថាន។ នេះ។ ម៉ាស៊ីនផលិតខ្នើយខ្យល់ក្រដាស អង្គុយនៅចំកណ្តាលនៃការវិវត្តន៍នេះ ដោយផ្សារភ្ជាប់គោលដៅបរិស្ថាន និងប្រសិទ្ធភាពផលិតកម្ម។

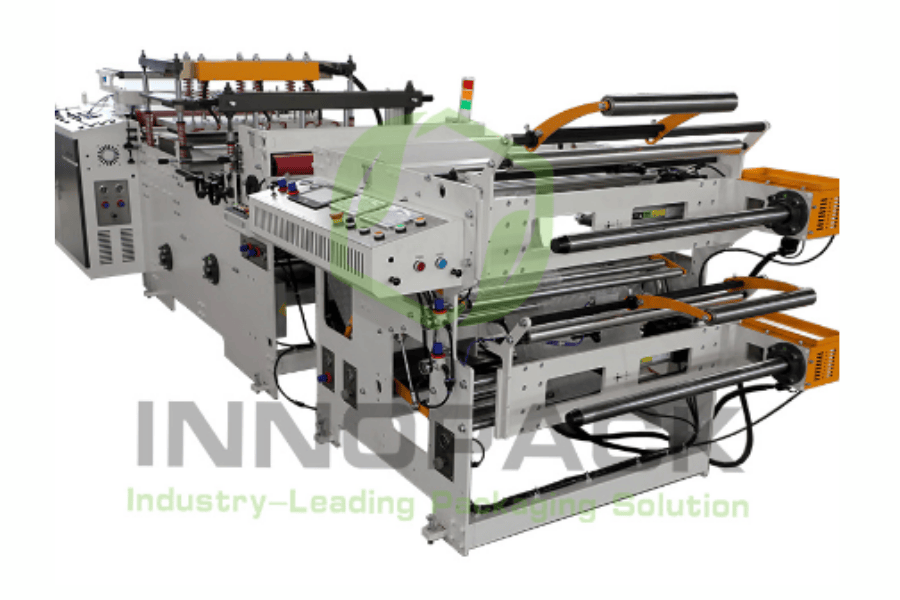

អ្នកផ្គត់ផ្គង់ម៉ាស៊ីនផលិតខ្នើយខ្យល់ក្រដាស

តើម៉ាស៊ីនផលិតខ្នើយខ្យល់ក្រដាសជាអ្វី?

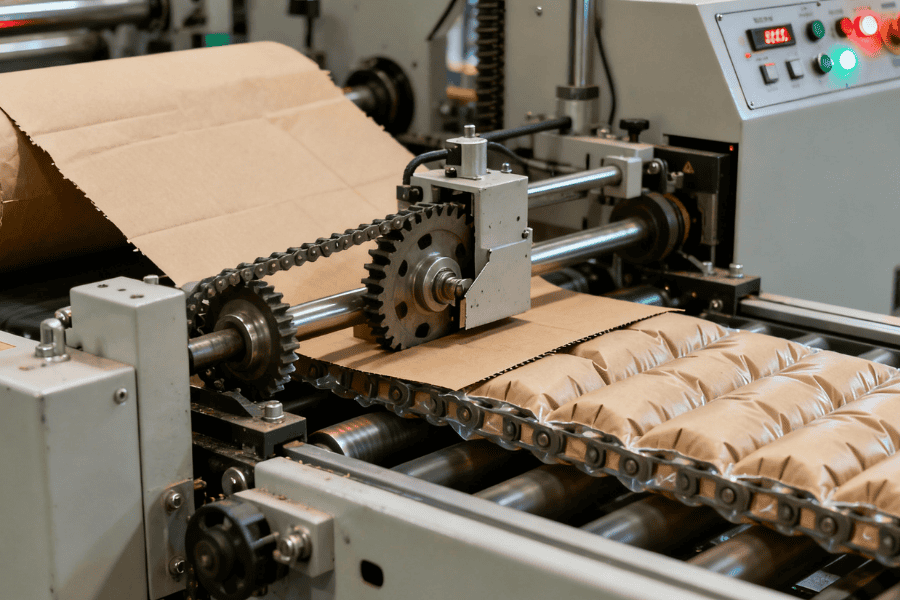

A ម៉ាស៊ីនផលិតខ្នើយខ្យល់ក្រដាស បំប្លែងក្រដាសក្រែបដែលអាចប្រើឡើងវិញបាន ឬក្រដាសស្រោបទៅជាខ្នើយដែលមានខ្យល់ដែលការពារទំនិញក្នុងពេលដឹកជញ្ជូន។ គំនិតនេះគឺសាមញ្ញ ប៉ុន្តែការប្រតិបត្តិគឺត្រូវបានវិស្វកម្មខ្ពស់ - ការផ្សាភ្ជាប់កំដៅដោយភាពជាក់លាក់ ការគ្រប់គ្រងភាពតានតឹង និងឧបករណ៍ចាប់សញ្ញាឆ្លាតវៃធានាថាខ្នើយនីមួយៗហើមជាប់គ្នា និងផ្សាភ្ជាប់យ៉ាងល្អឥតខ្ចោះ។

មិនដូចម៉ាស៊ីនពពុះប្លាស្ទិក ឬម៉ាស៊ីនខ្សែភាពយន្តទេ ប្រព័ន្ធទាំងនេះត្រូវបានរចនាឡើងដើម្បីធ្វើការជាមួយ សម្ភារៈក្រដាសគ្មាន PFAS ដែលមានមូលដ្ឋានលើជីវគីមីស្របតាមស្តង់ដារនិរន្តរភាព EU និងអាមេរិកខាងជើង។

អត្ថប្រយោជន៍សំខាន់ៗដោយក្រឡេកមើល

| លក្ខណៈ | ម៉ាស៊ីនផលិតខ្នើយខ្យល់ក្រដាស | ប្រព័ន្ធផ្លាស្ទិចប្រពៃណី |

| និរន្តរភាព | 100% kraft ដែលអាចប្រើឡើងវិញបានឬខ្សែភាពយន្តក្រដាស | ការកែច្នៃឡើងវិញមានកំណត់ សំណល់កន្លែងចាក់សំរាមកាន់តែខ្ពស់។ |

| ធន់ | ការពង្រឹងក្រដាសច្រើនស្រទាប់ទប់ទល់នឹងការវាយ | ខ្នើយខ្ពស់ ប៉ុន្តែងាយនឹងឋិតិវន្ត និងរលាយ |

| រូបភាពម៉ាក | សារ "គ្មានផ្លាស្ទិច" បង្កើនកេរ្តិ៍ឈ្មោះអេកូ | ត្រូវបានគេមើលឃើញថាមិនសូវមាននិរន្តរភាពនៅក្នុងរបាយការណ៍ ESG |

| ប្រសិទ្ធភាពចំណាយ | កាត់បន្ថយទម្ងន់ DIM និងថ្លៃដឹកជញ្ជូនលើស | តម្លៃសម្ភារៈទាប ប៉ុន្តែសម្ពាធសវនកម្មខ្ពស់ជាង |

| ការអនុលោមតាម | តម្រឹមយ៉ាងពេញលេញជាមួយការណែនាំ PPWR និង EPR | ប្រឈមមុខនឹងការរឹតបន្តឹងបទប្បញ្ញត្តិនាពេលអនាគត |

ការជ្រើសរើសសម្ភារៈ និងឧត្តមភាពផ្នែកវិស្វកម្ម

សម្ភារៈនិរន្តរភាព ជួបនឹងវិស្វកម្មទំនើប

ដំណើរការនៃម៉ាស៊ីនផលិតខ្នើយខ្យល់ អាស្រ័យលើវិទ្យាសាស្ត្រសម្ភារៈ ក៏ដូចជាភាពជាក់លាក់មេកានិច។ ក្រដាស kraft ធន់ខ្ពស់។, ថ្នាំកូតដែលធន់នឹងទឹក។, និង laminates ពហុស្រទាប់ អនុញ្ញាតឱ្យប្រព័ន្ធទាំងនេះផលិតខ្នើយដែលមានទម្ងន់ស្រាល និងប្រើប្រាស់បានយូរ។

លក្ខណៈសំខាន់ៗនៃសម្ភារៈ៖

ក្រដាសដែលមានការបញ្ជាក់ FSC ធានាប្រភពដែលទទួលខុសត្រូវ។

ស្រទាប់របាំងស្រេចចិត្តសម្រាប់ការគ្រប់គ្រងសំណើម។

ថ្នាំកូតដែលមិនមាន PFAS ដែលបំពេញតាមបទប្បញ្ញត្តិទំនាក់ទំនងអាហាររបស់ FDA និងសហភាពអឺរ៉ុប។

រមៀលនីមួយៗឆ្លងកាត់ ការគ្រប់គ្រងភាពតានតឹងដែលជំរុញដោយ servoធានាម៉ាសុីនស្អាត ជាប់ស្អិត។ របស់ម៉ាស៊ីន ឧបករណ៍ចាប់សញ្ញារង្វិលជុំបិទ ត្រួតពិនិត្យសីតុណ្ហភាព ល្បឿន និងលំហូរខ្យល់ក្នុងពេលជាក់ស្តែង កាត់បន្ថយកាកសំណល់ និងបង្កើនប្រសិទ្ធភាពថាមពល។

បច្ចេកវិទ្យាផលិតកម្មកម្រិតខ្ពស់ និងប្រសិទ្ធភាព

ម៉ាស៊ីនផលិតខ្នើយខ្យល់ក្រដាសទំនើបត្រូវបានបំពាក់ជាមួយ ម៉ូឌុលស្វ័យប្រវត្តិកម្មឆ្លាតវៃ. ទាំងនេះរួមមាន:

ប្រព័ន្ធខ្សែស្រឡាយដោយស្វ័យប្រវត្តិ សម្រាប់ការផ្លាស់ប្តូររមៀលរហ័ស។

របារផ្សាភ្ជាប់ដែលអាចប្រែប្រួលសីតុណ្ហភាព ដែលលៃតម្រូវទៅនឹងថ្នាក់ក្រដាស។

ការគ្រប់គ្រងអេក្រង់ប៉ះ PLC + HMIអនុញ្ញាតឱ្យប្រតិបត្តិករដំណើរការបន្ទាត់ផលិតផលជាច្រើនជាមួយនឹងពេលវេលារងចាំតិចតួចបំផុត។

ការរចនាម៉ូឌុល សម្រាប់ការរួមបញ្ចូលជាមួយអ្នកផ្ញើក្រដាស ឬស្ថានីយរុំ។

បើប្រៀបធៀបទៅនឹងប្រព័ន្ធប្លាស្ទីកចាស់ៗ ម៉ាស៊ីនទាំងនេះដំណើរការក្នុងល្បឿនស្រដៀងគ្នា ឬខ្ពស់ជាងនេះ ខណៈពេលដែលការលុបបំបាត់ការបង្កើតឋិតិវន្ត និងការកែលម្អភាពត្រឹមត្រូវនៃការវេចខ្ចប់សម្រាប់ពាណិជ្ជកម្មអេឡិចត្រូនិក និងទំនិញដែលផុយស្រួយ។

កម្មវិធីម៉ាស៊ីនផលិតខ្នើយខ្យល់ក្រដាស

ការយល់ដឹងពីអ្នកជំនាញ

សារ៉ាលីន, ការត្រួតពិនិត្យភ័ស្តុភារ ArchDaily (2024):

"ប្រព័ន្ធវេចខ្ចប់ក្រដាសឥឡូវនេះតំណាងឱ្យការផ្លាស់ប្តូរដ៏សំខាន់នៃការច្នៃប្រឌិតសម្ភារៈ។ ក្រុមហ៊ុនដែលទទួលយកម៉ាស៊ីនខ្នើយខ្យល់ក្រដាសទទួលបានទាំងការត្រៀមខ្លួនសម្រាប់ការអនុលោមភាព និងភាពខុសគ្នានៃម៉ាកយីហោ"។

វេជ្ជបណ្ឌិត Emily Carter, MIT Materials Lab (2023):

"ខ្នើយខ្យល់ kraft ដែលកែច្នៃបានត្រឹមត្រូវអាចទទួលបានភាពធន់ទ្រាំនឹងការធ្លាក់ចុះដែលអាចប្រៀបធៀបទៅនឹងខ្នើយ LDPE ជាពិសេសនៅពេលផលិតដោយប្រើប្រព័ន្ធផ្សាភ្ជាប់ដែលគ្រប់គ្រងដោយ servo ។"

របាយការណ៍ឧស្សាហកម្ម PMMI (2024)៖

ការដឹកជញ្ជូនសកលរបស់ ម៉ាស៊ីនវេចខ្ចប់ក្រដាស បានកើនឡើង 18% ពីមួយឆ្នាំទៅមួយឆ្នាំជាមួយនឹងប្រព័ន្ធខ្នើយខ្យល់តំណាងឱ្យ ប្រភេទរងដែលរីកលូតលាស់លឿនបំផុត។ ដោយសារតែសម្ពាធបទប្បញ្ញត្តិ និងតម្រូវការទីផ្សារ។

ទិន្នន័យវិទ្យាសាស្ត្រ និងការយល់ដឹងអំពីទីផ្សារ

របាយការណ៍វេចខ្ចប់ EU (2023)៖ 83% នៃអ្នកផ្តល់សេវាភស្តុភារបានកំណត់អត្តសញ្ញាណការវេចខ្ចប់ក្រដាសដែលអាចកែច្នៃឡើងវិញបានថាជាអាទិភាពវិនិយោគកំពូលរបស់ពួកគេ។

ការសិក្សា EPA (2024)៖ ការវេចខ្ចប់ក្រដាសឥឡូវនេះមានអត្រាកែច្នៃឡើងវិញ 68% ដែលជាកម្រិតខ្ពស់បំផុតក្នុងចំណោមប្រភេទសម្ភារៈទាំងអស់។

ទិនានុប្បវត្តិនៃភស្តុភារប្រកបដោយនិរន្តរភាព (2023)៖ ការផ្លាស់ប្តូរទៅប្រព័ន្ធខ្នើយខ្យល់ក្រដាសកាត់ ទម្ងន់ DIM ចំណាយ 15% ជាមធ្យម។

McKinsey Packaging Outlook (2025)៖ ការវេចខ្ចប់ប្រកបដោយនិរន្តរភាពនឹងតំណាងឱ្យ 45% នៃការវិនិយោគលើម៉ាស៊ីនវេចខ្ចប់ទាំងអស់។ នៅឆ្នាំ 2027 ។

ករណីសិក្សា និងការអនុវត្តជាក់ស្តែង

អ្នកលក់រាយតាមអេឡិចត្រូនិក

បន្ទាប់ពីប្តូរពីខ្នើយផ្លាស្ទិចទៅជាខ្នើយខ្យល់ក្រដាស ម៉ាកពាណិជ្ជកម្មអេឡិចត្រូនិកឈានមុខគេបានរាយការណ៍ថា៖

19% របស់ខូចខាតតិចជាង ក្នុងអំឡុងពេលដឹកជញ្ជូន។

30% លឿនជាងមុនក្នុងការតម្រៀប និងពេលវេលាវេចខ្ចប់.

ការកែច្នៃឡើងវិញយ៉ាងសាមញ្ញនៅទូទាំងមជ្ឈមណ្ឌលបំពេញទាំងអស់។

អ្នកផ្គត់ផ្គង់អេឡិចត្រូនិច

ខ្សែខ្នើយខ្យល់ក្រដាសរួមបញ្ចូលគ្នាដើម្បីការពារឧបករណ៍តម្លៃមធ្យម។

សម្រេចបាន។ 12% ការសន្សំលើការដឹកជញ្ជូន ដោយសារតែទម្ងន់ DIM ទាប។

ការពង្រឹងការរាយការណ៍ការអនុលោមតាមច្បាប់ក្រោមការទទួលខុសត្រូវរបស់អ្នកផលិតបន្ថែមរបស់សហភាពអឺរ៉ុប (EPR) ។

ម៉ាកគ្រឿងសំអាង

បានទទួលយកប្រព័ន្ធខ្នើយក្រដាសសម្រាប់សោភ័ណ្ឌភាពវេចខ្ចប់ដ៏ប្រណិត។

បទពិសោធន៍នៃការដោះប្រអប់កាន់តែប្រសើរឡើង និងបង្កើនការវាយតម្លៃការពេញចិត្តរបស់អតិថិជនដោយ 22%.

គ្រឿងម៉ាស៊ីន innopack ត្រូវបានគេស្គាល់ថាសម្រាប់ម៉ាស៊ីនផលិតខ្នើយខ្យល់ដែលផលិតដោយភាពជាក់លាក់ផ្នែកវិស្វកម្ម ដែលរួមបញ្ចូលគ្នានូវនិរន្តរភាពជាមួយនឹងភាពជឿជាក់។ ប្រព័ន្ធម៉ូឌុលរបស់យើងគាំទ្រអ្នកផលិតក្នុងការសម្រេចបាននូវប្រសិទ្ធភាព ការអនុលោមភាព និងកេរ្តិ៍ឈ្មោះម៉ាកនៅក្នុងភស្តុភារសកល។

មតិអ្នកប្រើ

"ការប្តូរទៅខ្នើយខ្យល់ក្រដាសបានកាត់បន្ថយទាំងការចំណាយលើការខ្ជះខ្ជាយ និងថ្លៃដឹកជញ្ជូន។" — អ្នកគ្រប់គ្រងប្រតិបត្តិការ ក្រុមហ៊ុនដឹកជញ្ជូន

"សវនកម្មវេចខ្ចប់របស់យើងឥឡូវនេះឆ្លងកាត់ដោយគ្មានឯកសារបន្ថែម - សន្សំសំចៃពេលវេលាដ៏ធំ។" — នាយក ESG ម៉ាក E-Commerce

"ភាពបត់បែនរបស់ម៉ាស៊ីនអាចឱ្យយើងប្តូររវាងក្រដាស និងសម្ភារៈកូនកាត់ភ្លាមៗ។" — វិស្វកររោងចក្រ កន្លែងវេចខ្ចប់

ម៉ាស៊ីនផលិតខ្នើយខ្យល់ក្រដាសគុណភាពខ្ពស់

សំណួរគេសួរញឹកញាប់

1. តើម៉ាស៊ីនផលិតខ្នើយខ្យល់ក្រដាសគឺជាអ្វី?

ម៉ាស៊ីនដែលបំលែងក្រដាស kraft ដែលអាចកែច្នៃឡើងវិញបានទៅជាខ្នើយដែលពោរពេញដោយខ្យល់សម្រាប់ការវេចខ្ចប់ដែលមិនប៉ះពាល់ដល់បរិស្ថាន។

2. តើវាប្រើប្រាស់បានយូរដូចខ្នើយខ្យល់ផ្លាស្ទិចដែរឬទេ?

បាទ។ រចនាសម្ព័ន្ធក្រដាសដែលបានពង្រឹងទំនើប និងការផ្សាភ្ជាប់យ៉ាងច្បាស់លាស់ផ្តល់នូវការការពារសមមូលសម្រាប់ផលិតផលភាគច្រើន។

3. តើវាអាចកាត់បន្ថយថ្លៃដឹកជញ្ជូនបានទេ?

ដាច់ខាត។ ខ្នើយខ្យល់ក្រដាសមានទម្ងន់ស្រាល កាត់បន្ថយទម្ងន់វិមាត្រ និងកាត់បន្ថយថ្លៃដឹកជញ្ជូនលើស។

4. តើឧស្សាហកម្មអ្វីប្រើម៉ាស៊ីននេះ?

វិស័យពាណិជ្ជកម្មតាមប្រព័ន្ធអេឡិចត្រូនិក ភស្តុភារ អេឡិចត្រូនិក គ្រឿងសម្អាង និងទំនិញគេហដ្ឋានប្រើប្រាស់វាយ៉ាងទូលំទូលាយដើម្បីធ្វើឱ្យមានតុល្យភាពនៃការការពារ និងនិរន្តរភាព។

5. តើវាសមរម្យសម្រាប់ការអនុលោមតាមលក្ខណៈសកលទេ?

បាទ។ បច្ចេកវិទ្យានេះស្របតាមអាណត្តិនៃការវេចខ្ចប់ដោយគ្មាន PPWR, EPR និង PFAS នៅអឺរ៉ុប សហរដ្ឋអាមេរិក និងអាស៊ី។

ឯកសារយោង

-

សារ៉ាលីន, ការត្រួតពិនិត្យភ័ស្តុភារ ArchDaily (2024) - "ការច្នៃប្រឌិតម៉ាស៊ីនវេចខ្ចប់ដែលជំរុញឱ្យមានការដឹកជញ្ជូនប្រកបដោយនិរន្តរភាព។"

-

វេជ្ជបណ្ឌិត Emily Carter, MIT Materials Lab (2023) - "ការសិក្សាប្រៀបធៀបនៃក្រដាស kraft និងភាពធន់នៃខ្នើយខ្យល់ LDPE"

-

របាយការណ៍ឧស្សាហកម្ម PMMI (2024) - "កំណើនទីផ្សារគ្រឿងចក្រវេចខ្ចប់សកល និងនិន្នាការឆ្នាំ 2025"។

-

របាយការណ៍ EPA (2024) - "ទិន្នន័យការកែច្នៃនិងការកាត់បន្ថយកាកសំណល់របស់សហរដ្ឋអាមេរិកសម្រាប់សម្ភារវេចខ្ចប់។"

-

របាយការណ៍អនុលោមភាពវេចខ្ចប់របស់សហភាពអឺរ៉ុប (2023) - "ការផ្លាស់ប្តូរប្រកបដោយនិរន្តរភាពនៅក្នុងប្រព័ន្ធវេចខ្ចប់អ៊ឺរ៉ុប។"

-

ទិនានុប្បវត្តិនៃភស្តុភារប្រកបដោយនិរន្តរភាព (2023) - "ផលប៉ះពាល់នៃបច្ចេកវិទ្យាខ្នើយខ្យល់លើប្រសិទ្ធភាពដឹកជញ្ជូន"

-

McKinsey & Company (2025) - "ទស្សនវិស័យការវេចខ្ចប់ប្រកបដោយនិរន្តរភាព និងនិន្នាការវិនិយោគទុន។"

-

ការវេចខ្ចប់អឺរ៉ុប (2024) - "ដំណោះស្រាយក្រដាស-ប្លាស្ទីកកូនកាត់ក្នុងភស្តុភារទំនើប។"

-

អង្គការវេចខ្ចប់ពិភពលោក (2024) - "ការច្នៃប្រឌិតអេកូ និងសេដ្ឋកិច្ចរាងជារង្វង់ក្នុងការវេចខ្ចប់។"

-

ក្រដាសសបច្ចេកទេសគ្រឿងម៉ាស៊ីន Innopack (2025) - "ការយល់ដឹងផ្នែកវិស្វកម្មទៅលើប្រព័ន្ធខ្នើយខ្យល់ដែលគ្រប់គ្រងដោយក្រដាស Servo"។

ដោយសារនិរន្តរភាពក្លាយជារូបិយប័ណ្ណថ្មីនៃការប្រកួតប្រជែងក្នុងឧស្សាហកម្ម ម៉ាស៊ីនផលិតខ្នើយខ្យល់ក្រដាសឈរជាស្ពានរវាងការអនុវត្ត និងការទទួលខុសត្រូវផ្នែកបរិស្ថាន។ យោងតាមលោកវេជ្ជបណ្ឌិត Emily Carter (MIT Materials Lab) ប្រព័ន្ធផ្សាភ្ជាប់ដែលជំរុញដោយ servo ចុងក្រោយបង្អស់បានធ្វើឱ្យក្រដាសក្រដាស kraft ធន់នឹងផលប៉ះពាល់ដូចជាប្លាស្ទិក LDPE ដោយគ្មានបន្ទុកកាបូន។Sarah Lin (ArchDaily Trends) បន្ថែមថាក្រុមហ៊ុនផលិតដែលប្រើប្រាស់ប្រព័ន្ធខ្យល់ក្រដាសនៅដំណាក់កាលដំបូងគឺសម្រេចបានមិនត្រឹមតែការអនុលោមប៉ុណ្ណោះទេ ប៉ុន្តែគុណសម្បត្តិទីផ្សារដែលអាចវាស់វែងបាន។ ការផ្លាស់ប្តូរអេកូលែងជានិមិត្តសញ្ញាទៀតហើយ។ វាអាចគណនាបានក្នុងការសន្សំសំចៃផ្នែកដឹកជញ្ជូន កាត់បន្ថយការគិតថ្លៃ DIM និងអត្រាការខូចខាតទាប។

ខ្សែសង្វាក់ផ្គត់ផ្គង់សកលកំពុងឈានចូលដល់យុគសម័យដែលភាពវៃឆ្លាតខាងសម្ភារៈ និងភាពជាក់លាក់នៃម៉ាស៊ីនបញ្ចូលគ្នា។ សម្រាប់រោងចក្រ អ្នកចែកចាយ និងក្រុមហ៊ុនពាណិជ្ជកម្មអេឡិចត្រូនិកយក្ស ការផ្លាស់ប្តូរទៅជាខ្នើយដែលមានមូលដ្ឋានលើក្រដាសគឺច្រើនជាងការសន្សំថ្លៃដើម - វាគឺជាការវិវត្តម៉ាកយីហោ។

នៅក្នុងពាក្យនៃរបាយការណ៍ឆ្នាំ 2024 របស់ PMMI "ស្វ័យប្រវត្តិកម្ម និងនិរន្តរភាពមិនមែនជាអាទិភាពដាច់ដោយឡែកពីគ្នាទៀតទេ - ពួកគេគឺជាគោលដៅដូចគ្នា" ។ ក្រុមហ៊ុនដែលធ្វើតាមគោលការណ៍នេះនៅថ្ងៃនេះ នឹងក្លាយជាក្រុមហ៊ុននាំមុខគេក្នុងពិភពភស្តុភារនៅថ្ងៃស្អែក។