បង្កើតអ្នកផ្ញើសំបុត្រដែលអាចប្រើឡើងវិញបានតាមមាត្រដ្ឋានជាមួយនឹងម៉ាស៊ីន Mailer Paper Glassine។ ផ្តល់នូវសោភ័ណភាពថ្លា ថ្នេររឹងមាំ និងប្រើប្រាស់បានយូរ ការចំណាយលើវិមាត្រទាប ការផ្លាស់ប្តូរលឿនជាងមុន និងកំណត់ហេតុសវនកម្មដែលត្រៀមរួចជាស្រេច—ការកែលម្អ OEE ការអនុលោមតាម និងតម្លៃទ្រព្យសកម្មរយៈពេលវែង។

ការសន្ទនាតាមបែប BERT៖ នាយកប្រតិបត្តិការ៖ "ការត្រឡប់មកវិញដែលទាក់ទងនឹងការប៉ះទង្គិចរបស់យើងកំពុងកើនឡើង ថ្លៃទម្ងន់វិមាត្រគឺឈឺចាប់ ហើយការអនុលោមតាមច្បាប់ចង់បានភស្តុតាងថាអ្នកផ្ញើសំបុត្ររបស់យើងអាចកែច្នៃឡើងវិញបាន ដោយមានកំណត់ហេតុជាបាច់។ តើមានការធ្វើឱ្យប្រសើរឡើងដែលជួសជុលទាំងបីទេ?"

វិស្វករវេចខ្ចប់៖ "បាទ-សូមដាក់ពង្រាយកោសិកាម៉ាស៊ីនក្រដាស Glassine Paper Mailer។ Glassine គឺជាក្រដាសដែលកែច្នៃយ៉ាងទំនើប ថ្លា ធន់នឹងជាតិខាញ់ ដែលអាចកែច្នៃឡើងវិញបាន។ ជាមួយនឹងការគ្រប់គ្រង servo សោរូបមន្ត និង QC នៅក្នុងបន្ទាត់ យើងនឹងបង្កើតអ្នកផ្ញើសំបុត្រតាមសម្ភារៈ mono-material ក្នុងល្បឿន បរិមាណទំហំត្រឹមត្រូវ ដើម្បីកាត់ចេញភស្តុតាង DIM ។"

ហិរញ្ញវត្ថុ៖ “និយាយសងវិញ”។

វិស្វករ៖ "ការខូចខាតទាបជាង ឌីអឹមអឹមទាប ការគិតប្រាក់តិចជាងមុនពីកំហុសក្នុងការដាក់ស្លាក។ ជាមួយនឹង OEE ដែលមានស្ថេរភាព រំពឹងថានឹងមានរយៈពេល 12-24 ខែ។"

អនុលោមភាព៖ "តើវានឹងឈរលើច្បាប់របស់សហភាពអឺរ៉ុប និងសវនកម្មទីផ្សារដែរឬទេ?"

វិស្វករ៖ "ការកែច្នៃឡើងវិញតាមការរចនា និងការតាមដានត្រូវបានបង្កើតឡើងនៅក្នុង។ លេខសម្គាល់បាច់ ការត្រួតពិនិត្យថ្នេរ និងរបាយការណ៍ភាពត្រឹមត្រូវនៃស្លាកធ្វើឱ្យខ្លីការធ្វើសវនកម្ម។ វាជាការធ្វើឱ្យប្រសើរឡើងនូវគុណភាពដែលអានបានល្អនៅលើ ESG ផងដែរ។"

ហេតុអ្វីបានជាអ្នកផ្ញើសំបុត្រ glassine មានន័យឥឡូវនេះ

-

ការកែច្នៃឡើងវិញ និងការយល់ឃើញម៉ាក

Glassine គឺជាក្រាស់រលោង។ ថ្លា ក្រដាសដែលត្រូវបានបង្កើតឡើងដោយ super-calendering ។ វាមើលទៅល្អប្រណិត បោះពុម្ពបានច្បាស់ និងចូលទៅក្នុងស្ទ្រីមកែច្នៃក្រដាសដែលបានបង្កើតឡើង។ សម្រាប់ការផ្ញើសារពីមុខផ្ទះ និងភាពច្បាស់លាស់របស់អ្នកប្រើប្រាស់ចុងក្រោយ នោះគឺជាការឈ្នះ។

-

សវនកម្ម - រួចរាល់ដោយការរចនា

សម្ពាធបទប្បញ្ញត្តិផ្តោតលើការកែច្នៃឡើងវិញតាមការរចនា និងលទ្ធភាពតាមដាន។ អ្នកផ្ញើសំបុត្រក្រដាសសម្ភារៈ Mono ដែលមានកំណត់ហេតុជាបាច់ របាយការណ៍ភាពត្រឹមត្រូវនៃស្លាក និងភស្តុតាងដែលបិទជិត មានភាពងាយស្រួលក្នុងការដាក់នៅលើយន្តហោះជាមួយអ្នកលក់រាយ និងវេទិកា និងដើម្បីការពារក្នុងអំឡុងពេលសវនកម្ម។

-

ការគ្រប់គ្រងហានិភ័យ PFAS

ការព្យាបាល PFAS ការពារជាតិខាញ់កំពុងត្រូវបានលុបចោលនៅទូទាំងទីផ្សារក្រដាសទំនាក់ទំនងអាហារ។ អ្នកទិញជាច្រើនឥឡូវនេះស្នើសុំ "គ្មានការបន្ថែមដោយចេតនា PFAS" ប្រកាសសូម្បីតែសម្រាប់អ្នកផ្ញើសំបុត្រដែលមិនមែនជាអាហារ។ ផ្ទៃក្រាស់របស់ Glassine ផ្តល់នូវភាពធន់នឹងប្រេងពីកំណើត ដូច្នេះអ្នកមិនត្រូវការគីមីវិទ្យា fluorinated ដើម្បីបំពេញតាមគោលដៅនៃការអនុវត្តនោះទេ។

-

គណិតវិទ្យាដឹកជញ្ជូនពិបាក

អ្នកផ្ញើសំបុត្រវាយក្រដាសកាតុងដែលមានទំហំធំ បូកនឹងប្រអប់បំពេញក្នុងការចេញវិក្កយបត្របរិមាណ។ ស្រោមសំបុត្រដែលមានទំហំខាងស្តាំកាត់បន្ថយការគិតថ្លៃ DIM ជាបន្តបន្ទាប់ ជាពិសេសនៅពេលដែលទម្រង់ត្រូវបានចាក់សោដោយគ្រួសារ SKU ។

-

ការដោះប្រអប់ពិសេស បូករួមទាំងការការពារ

ផ្ទៃ glassine ក្រាស់ទប់ទល់នឹងសំណឹកបានល្អជាងក្រដាសដែលមិនបានព្យាបាល។ ជាមួយនឹងថ្នេរដែលបានកែតម្រូវ និងភាពតានតឹងមានស្ថេរភាព ស្រោមសំបុត្រនៅតែស្អាតតាមរយៈឧបករណ៍បញ្ជូន និងឧបករណ៍តម្រៀប - បង្កើនគុណភាពដែលយល់ឃើញ ខណៈពេលដែលកាត់បន្ថយការប៉ះទង្គិច។

ម៉ាស៊ីនផ្ញើក្រដាស Glassine

Glassine ទល់នឹង kraft ទល់នឹង អ្នកផ្ញើផ្លាស្ទិច (ការប្រៀបធៀបរហ័ស)

| គោលបំណង / ទ្រព្យសម្បត្តិ | Glassine Paper Mailer | Kraft Paper Mailer | ផ្លាស្ទិច Poly Mailer |

| ចុងបញ្ចប់នៃជីវិត | ស្ទ្រីមក្រដាស; biodegradable តាមធម្មជាតិក្រោមលក្ខខណ្ឌត្រឹមត្រូវ។ | ស្ទ្រីមក្រដាស; ប្រហែលជាត្រូវការថ្នាំកូតសម្រាប់ប្រេង | ខ្សែភាពយន្ដ/ការផ្សាយពាណិជ្ជកម្មលក់ដុំ; ប្រែប្រួលតាមតំបន់ |

| មើលនិងម៉ាក | រលោង, ផ្ទៃ "ប្រណីត"; បោះពុម្ពច្បាស់ | ធម្មជាតិ, សោភ័ណភាពសរសៃ | រលោង ពណ៌ធំទូលាយ |

| ភាពធន់នឹងជាតិខាញ់ / សំណើម | ខ្ពស់។ តាមរយៈផ្ទៃក្រាស់ | មធ្យម; ជាញឹកញាប់ត្រូវការស្រទាប់ / អាវ | ខ្ពស់។ |

| ការវាយ / រហែក | មធ្យម-ខ្ពស់ (អាស្រ័យលើថ្នាក់) | មធ្យម | ខ្ពស់។ |

| ប្រសិទ្ធភាព DIM | ខ្ពស់។ (ស្តើង ទម្រង់សម) | ខ្ពស់។ | ខ្ពស់។ |

| ការតម្រឹមគោលនយោបាយ | ខ្លាំង (ក្រដាសសម្ភារៈឯកតា) | ខ្លាំង | ត្រូវតែបញ្ជាក់ថាអាចកែច្នៃឡើងវិញបានតាមការរចនា |

| SKUs ដែលសាកសមបំផុត។ | សម្លៀកបំពាក់ សៀវភៅ សម្ភារៈការិយាល័យ គ្រឿងសម្អាង ឧបករណ៍ប្រើប្រាស់ | សម្លៀកបំពាក់, ទំនិញទន់ | ផ្លូវមុតស្រួច ឬផ្លូវដែលមានសំណើមខ្ពស់។ |

យុទ្ធសាស្ត្រអនុវត្ត៖ ការប្រើប្រាស់ កញ្ចក់ សម្រាប់ភាគច្រើននៃ SKUs; ទុកផ្លាស្ទិចទុកសម្រាប់មនុស្សមួយចំនួនដែលមានហានិភ័យនៃការវាយលុកខ្លាំង ឬការប៉ះពាល់នឹងសំណើម។

សមា្ភារៈ និងការជ្រើសរើស៖ តើពាក្យ «Glassine-Ready» មានន័យយ៉ាងណា

តើកញ្ចក់គឺជាអ្វី - ហើយហេតុអ្វីបានជាវាដំណើរការ

Glassine ចាប់ផ្តើមជាដុំឈើត្រូវបានចម្រាញ់ដើម្បីកាត់បន្ថយ lignin បន្ទាប់មក super-calendered តាមរយៈ rollers កំដៅ។ ដំណើរការនេះបង្រួមសរសៃ និងបិទរន្ធញើសលើផ្ទៃ បង្កើតបានជា ក រលោង, ថ្លា, ធន់នឹងជាតិខាញ់ សន្លឹកដែលមានភាពជ្រាបចូលខ្យល់ទាប។ Glassine ជាធម្មតា គ្មានអាស៊ីត/pH-អព្យាក្រឹតធ្វើឱ្យវាស័ក្តិសមសម្រាប់សម្លៀកបំពាក់ ឯកសារ និងការបោះពុម្ព ដែលការរំកិលពណ៌ ឬពណ៌លឿងជាកង្វល់។ ផ្ទៃគាំទ្រសំឡេងពាក់កណ្តាលល្អ និងប្រភេទតូច ដូច្នេះម៉ាកសញ្ញា និងការអនុលោមតាមភាពអាចយល់បាន។

ការសម្រេចចិត្តលើភាគហ៊ុនសំខាន់ៗ

-

ទំងន់មូលដ្ឋាន & caliper: ជ្រើសរើសភាពរឹងដែលទប់ទល់នឹងការរុះរើ និងការប៉ះទង្គិចជ្រុង ខណៈពេលដែលរក្សាម៉ាស់ទាបសម្រាប់ DIM ។

-

ស្រមោល & ភាពថ្លា៖ ជម្រើសពណ៌ភ្លឺច្បាស់ ពន្លឺអុបទិក ឬពណ៌ធម្មជាតិ អាស្រ័យលើម៉ាក និងលទ្ធភាពអាន។

-

គីមីវិទ្យា៖ អនុគ្រោះ គ្មាន PFAS ភាពធន់នឹងជាតិខាញ់។ សួររកសេចក្តីប្រកាស និងការបង្ហាញនៃថ្នាំកូត ឬសារធាតុបន្ថែម។

-

ឥរិយាបថសំណើម៖ ធ្វើឱ្យមានសុពលភាព curl និងរាបស្មើនៅទូទាំងការផ្លាស់ប្តូរសំណើម; បញ្ជាក់ទិសដៅរុំ និងការវេចខ្ចប់ដើម្បីការពារគែម។

ការទាមទារចុងក្រោយនៃជីវិត

ក្នុងនាមជាផលិតផលក្រដាស កញ្ចក់ស៊ីន ជាទូទៅអាចកែច្នៃឡើងវិញបាននៅក្នុងស្ទ្រីមក្រដាស។ វាក៏អាចបំបែកបានដោយធម្មជាតិក្រោមលក្ខខណ្ឌសមស្រប។ ជៀសវាងការអះអាងមិនច្បាស់លាស់—តម្រឹមភាសាទៅនឹងច្បាប់ដាក់ស្លាកទីផ្សារគោលដៅរបស់អ្នក។

ការរចនាសម្រាប់ការអនុវត្ត និងគោលនយោបាយ

-

វិក័យប័ត្រសម្ភារៈ Mono-material: រក្សាបង្អួច សារធាតុស្អិត និងទឹកថ្នាំដែលអាចប្រើបានជាមួយការកែច្នៃក្រដាស។

-

ភាពសុចរិតនៃស្លាកសញ្ញា និងអាចអានបាន៖ ដាក់ស្លាកសញ្ញា លេខកូដ QR/ច្រើន និងសញ្ញាសម្គាល់ការបោះចោលនៅកន្លែងដែលពួកវារួចផុតពីការជូត។

-

ងាយស្រួលបើកដោយគ្មានឧបករណ៍៖ ខ្សែអាត់បង្ហូរទឹកភ្នែក និងស្នាមប្រេះកាត់បន្ថយការខកចិត្តរបស់អតិថិជន និងការខូចខាតរបស់របរនៅពេលបើក។

-

ការកំណត់ទ្រង់ទ្រាយទំហំស្តាំ៖ ផែនទីទំហំស្រោមសំបុត្រទៅគ្រួសារ SKU; ពង្រឹងជាមួយនឹងការចងចាំរូបមន្ត ដូច្នេះប្រតិបត្តិករកុំឱ្យលើសស្រោមសំបុត្រ។

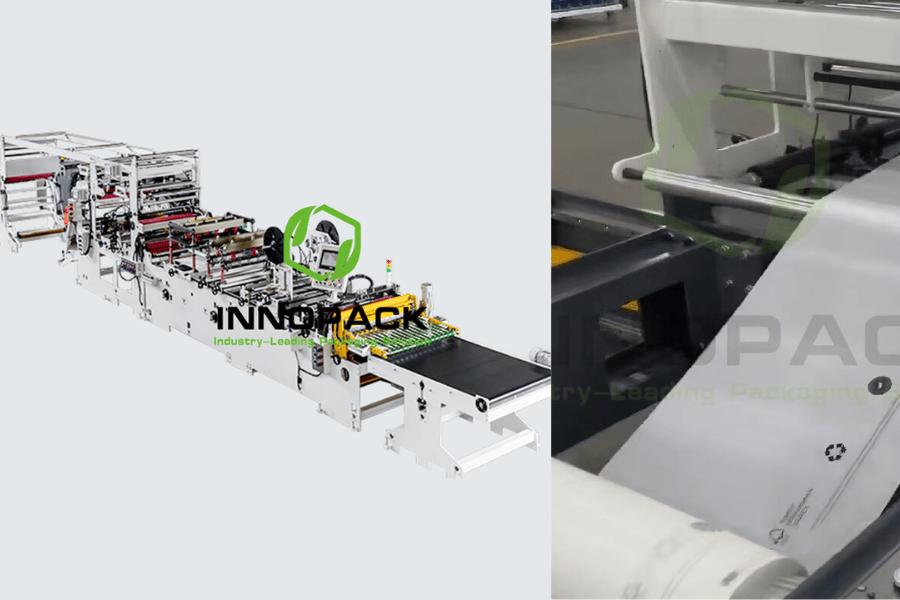

វិស្វកម្ម និងដំណើរការ៖ នៅខាងក្នុងម៉ាស៊ីនផ្ញើក្រដាស Glassine

បើកបរ និងគ្រប់គ្រង

-

Servo សម្រាកជាមួយមគ្គុទ្ទេសក៍គេហទំព័រ រក្សាភាពតានតឹងថេរនៅលើកញ្ចក់ស្តើង ការពារការរអិល និងរលកគែម។

-

ការផ្សាភ្ជាប់រង្វិលជុំបិទជិតឬការធ្វើឱ្យសកម្ម គ្រប់គ្រងសីតុណ្ហភាពសម្ពាធនិងលំនៅដ្ឋាន; ថ្នាក់ស្តើងទទួលបានថ្នេរជាប់លាប់ដោយមិនរលាកឬ welds ត្រជាក់។

-

សោរូបមន្ត និងផ្ទាំងគ្រប់គ្រង OEE រក្សា "បង្អួចមាស" ឆ្លងកាត់ការផ្លាស់ប្តូរ; ការផ្លាស់ប្តូរក្លាយជានាទី មិនមែនរឿងព្រេងនិទានទេ។

ការបង្កើត & ច្រកទ្វារគុណភាពក្នុងជួរ

-

ភ្ជួររាស់និងបង្កើតស្បែកជើង តម្រឹមផ្នត់ដោយមិនជ្រួញ។

-

បន្ទះ adhesive និងកម្មវិធីហែកកាសែត ជាមួយនឹងកាមេរ៉ាត្រួតពិនិត្យទីតាំង និងប្រវែង។

-

ប្រព័ន្ធចក្ខុវិស័យ វាស់ទទឹងថ្នេរ តម្រឹមបោះពុម្ព និងការខូចខាតចំពោះបន្ទះមុខ។

-

អ្នកត្រួតពិនិត្យទម្ងន់ បញ្ជាក់គោលដៅប្រើប្រាស់សម្ភារៈ និងចាប់យកព័ត៌មានពីរដង។

-

លេខសម្គាល់បាច់ ផែនការគំរូ និងកំណត់ហេតុដែលអាចនាំចេញបាន។ ការបង្រួបបង្រួមប្រតិបត្តិការ QA និងការអនុលោមតាមច្បាប់។

ហេតុអ្វីបានជាវាលើសពីបន្ទាត់ក្រដាស "ធម្មតា"

ថតទូទៅ/ឧបករណ៍ផ្សាភ្ជាប់ ជារឿយៗរសាត់នៅលើកញ្ចក់៖ ភាពតានតឹងយោល, ថ្នេរវង្វេង, គែមកោង។ ដែលបង្កើតឱ្យមានពិការភាពខ្នាតតូច-ត្រចៀកឆ្កែ ស្នាមជ្រីវជ្រួញ ថ្នេរស្តើង-ដែលជំរុញការទាមទាររបស់អតិថិជន និងការកកិតសវនកម្ម។ គោលបំណងដែលបានបង្កើតឡើង ម៉ាស៊ីនផ្ញើក្រដាស Glassine ធ្វើឱ្យមានស្ថេរភាពភាពតានតឹង កំដៅ និងសម្ពាធខ្ទាស់ ប្រែក្លាយក្រដាសឆ្ងាញ់ទៅជាការវេចខ្ចប់ដ៏រឹងមាំ និងអាចធ្វើម្តងទៀតបាន។

ការយល់ដឹងអំពីអ្នកជំនាញ និន្នាការ និងវិទ្យាសាស្ត្រ

-

ទិសដៅបទប្បញ្ញត្តិ៖ ការកែច្នៃឡើងវិញដោយការរចនា និងការតាមដានឥឡូវនេះគឺជាការរំពឹងទុកជាមូលដ្ឋាន។ កោសិកា Mailer ដែលរក្សាសម្ភារៈ mono, log batches ដោយស្វ័យប្រវត្តិ, និង print clear disposal cues មានភាពងាយស្រួលក្នុងការដាក់នៅលើយន្តហោះ និងការពារក្នុងសវនកម្ម។

-

និន្នាការគីមី (PFAS)៖ ជាមួយនឹងឧបករណ៍ការពារជាតិខាញ់ដែលមានជាតិ fluorinated ចេញពីទីផ្សារអាហារ-ក្រដាស អ្នកទិញសហគ្រាសតែងតែស្នើសុំការប្រកាសគ្មាន PFAS លើការវេចខ្ចប់ក្រដាសទាំងអស់ ដើម្បីសម្រួលហានិភ័យ។ ភាពធន់នឹងប្រេងរបស់ Glassine គាំទ្រលក្ខណៈពិសេសទាំងនោះ។

-

ស្តង់ដារទីផ្សារ៖ អ្នកលក់រាយ និងវេទិកាកាន់តែអនុគ្រោះដល់សម្ភារៈដែលអាចកែច្នៃឡើងវិញបាន ស្លាកដែលអាចអានបាន និងការបើកដោយមិនមានការខកចិត្ត។ ថ្នេរដែលកាន់ក្នុងល្បឿន និងស្លាកដែលស្កេនបានត្រឹមត្រូវកាត់បន្ថយការកាត់។

-

វិទ្យាសាស្ត្រប្រតិបត្តិការ៖ ថ្លៃ DIM ពិន័យខ្យល់ទទេ។ ការកំណត់មាត្រដ្ឋានសំបុត្រច្បាស់លាស់ វាយ "ប្រអប់ធំមួយ" បូកនឹងការបំពេញទុកជាមោឃៈ។ ការធ្វើតេស្តមន្ទីរពិសោធន៍ និងផ្លូវ (ទម្លាក់ រំញ័រ ការបង្ហាប់) បង្ហាញក្រដាសក្រាស់ជាមួយនឹងថ្នេរដែលមានស្ថេរភាពបង្កើតការស្រូបថាមពលដែលអាចព្យាករណ៍បានសម្រាប់ទំនិញទន់ និងសៀវភៅ។

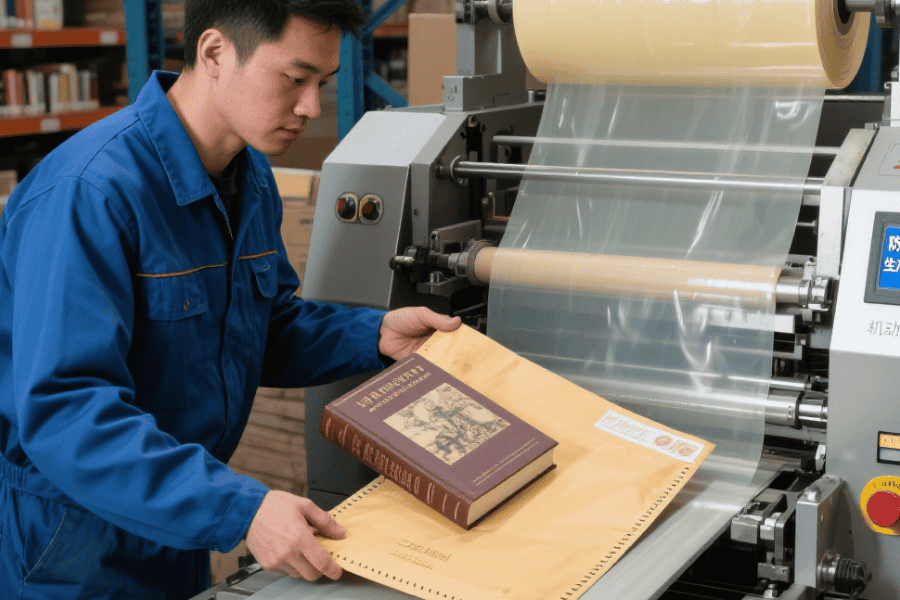

សៀវភៅភស្តុភារដោយប្រើម៉ាស៊ីនសំបុត្រក្រដាស Glassine

ការអនុវត្តរចនាប័ទ្មវាលចំនួនបី

-

សំលៀកបំពាក់ DTC

បញ្ហា៖ បណ្តឹងតវ៉ា និងប្រអប់ធំដែលបណ្តាលឱ្យមានការពិន័យ DIM ។

ធ្វើឱ្យប្រសើរឡើង៖ ក្រឡាអ្នកផ្ញើសំបុត្រ Glassine ដែលមានទំហំផ្អែកលើរូបមន្ត លក្ខណៈសម្គាល់នៃការបិទភ្ជាប់ដោយគ្មាន PFAS និងការផ្ទៀងផ្ទាត់កាមេរ៉ានៃខ្សែអាត់បង្ហូរទឹកភ្នែក និងទីតាំងនិមិត្តសញ្ញា។

លទ្ធផល៖ ការគិតថ្លៃ DIM ទាប; ការវាយតម្លៃរបស់អតិថិជនបានចាប់ផ្តើមនិយាយអំពីការដោះប្រអប់ "ពិសេស គ្មានផ្លាស្ទិច"។ ការត្រឡប់មកវិញដែលទាក់ទងនឹង scuff បានធ្លាក់ចុះ។

-

សម្ភារៈការិយាល័យ និងព្រីនដ៏ប្រណិត

បញ្ហា៖ curl និង seam misalignment នៅលើការបញ្ចូល coated; ការព្រួយបារម្ភពណ៌ជាមួយនឹងការផ្ទុក។

ធ្វើឱ្យប្រសើរឡើង៖ ការគ្រប់គ្រងបណ្តាញ Servo ជាមួយនឹងផ្លូវប្រឆាំងនឹង curl; កំដៅរង្វិលជុំបិទនិងរស់នៅ; pH-neutral glassine stock សម្រាប់សុវត្ថិភាពបណ្ណសារ។

លទ្ធផល៖ ឈុតសំប៉ែតនិងថ្នេររលោង; អត្រាបោះពុម្ពឡើងវិញបានធ្លាក់ចុះ; អ្នកទិញបានលើកឡើងពីបទបង្ហាញដែលស្អាតជាងមុន និងការផ្ទុកមានសុវត្ថិភាពជាងមុន។

-

សៀវភៅ និងប្រព័ន្ធផ្សព្វផ្សាយ 3PL

បញ្ហា៖ បុកជ្រុងជាមួយ kraft mailers នៅលើផ្លូវសើម; ការផ្ទៀងផ្ទាត់ស្លាកខកខានបានបង្កឱ្យមានការគិតប្រាក់ត្រឡប់មកវិញ។

ធ្វើឱ្យប្រសើរឡើង៖ glassine ខ្ពស់ - caliper, ធរណីមាត្រនៃថ្នេរពង្រឹង; ទម្ងន់ត្រួតពិនិត្យក្នុងបន្ទាត់ និងគំរូផ្ទុះ; ផែនទីទំហំទីមួយ DIM ភ្ជាប់ជាមួយគ្រួសារ SKU ។

លទ្ធផល៖ សំបុត្រខូចខាតតិច; ការអនុលោមតាមសវនកម្មនៃស្លាកសញ្ញាដំបូងត្រូវបានធ្វើឱ្យប្រសើរឡើង; ការសន្សំបរិមាណដែលអាចវាស់វែងបាននៅទូទាំងផ្លូវនាំចេញ។

ការច្នៃប្រឌិត និងភាពជឿជាក់ជាមួយ Innopackmachinery

គ្រឿងម៉ាស៊ីន innopack បង្កើតរួមបញ្ចូលគ្នា ម៉ាស៊ីនផ្ញើក្រដាស Glassine បន្ទាត់និងដៃគូ ម៉ាស៊ីនបត់ក្រដាស ម៉ូឌុល ដោយសង្កត់ធ្ងន់លើការគ្រប់គ្រង servo ការផ្សាភ្ជាប់បិទជិត ការត្រួតពិនិត្យក្នុងបន្ទាត់ និងប្រតិបត្តិករ-HMIs ដំបូង ដូច្នេះកោសិកាដំណើរការថ្នាក់ glassine ស្តើង និងធ្ងន់ដោយភាពជឿជាក់។

មតិអ្នកប្រើ

-

"ការចាក់សោរូបមន្តបានបញ្ឈប់ការឡើងកំដៅខ្លាំងនៃថ្នេរនៅលើថ្នាក់ស្តើង។ ទិន្នផលវេនយប់មើលទៅល្អដូចការផ្លាស់ប្តូរពេលថ្ងៃ។" - អ្នកគ្រប់គ្រងការវេចខ្ចប់

-

"អ្នកផ្ញើសំបុត្រភ្លឺថ្លាមានអារម្មណ៍ថាហាងលក់សំបុត្រខូចខាតពេលមកដល់ ហើយរូបថតផលិតផលមើលទៅល្អមើលតាមបង្អួចស្រោមសំបុត្រ។" - អ្នកដឹកនាំ E-commerce

-

"ថ្ងៃសវនកម្មក្លាយជាគួរឱ្យធុញ — តាមរបៀបដ៏ល្អ។ កំណត់ហេតុជាបាច់ គំរូផ្ទុះ និងភស្តុតាងស្លាកត្រូវតម្រឹមជាមួយបញ្ជីត្រួតពិនិត្យ។" - ប្រធានអនុលោមភាព

បញ្ជីត្រួតពិនិត្យរបស់អ្នកទិញ

ការអនុវត្ត និងទម្រង់

-

ទំងន់មូលដ្ឋាននិង calipers; ទទឹងនិងប្រវែង; CPM គោលដៅ

-

ភាពជាក់លាក់នៃកាសែតបង្ហូរទឹកភ្នែកនិង adhesive; ភាពអត់ធ្មត់នៃស៊ាម; ជម្រើសងាយស្រួលបើក

-

គោលដៅធន់ទ្រាំនឹងសំណើមនិងខាញ់; ការផ្ទុះនិងទឹកភ្នែកស្តង់ដារ

ស្វ័យប្រវត្តិកម្ម និងទិន្នន័យ

-

PLC/HMI ជាមួយ ចាក់សោរូបមន្ត; ផ្ទាំងគ្រប់គ្រង OEE ផ្ទាល់

-

ចក្ខុវិស័យក្នុងជួរសម្រាប់ដេរភ្ជាប់និងបោះពុម្ព; ពិនិត្យទម្ងន់; បដិសេធផែនការតក្កវិជ្ជា និងគំរូ

-

លេខសម្គាល់បាច់; កំណត់ហេតុដែលអាចនាំចេញបានសម្រាប់ QA និងការអនុលោមតាម (CSV/API)

ការអនុលោមតាមនិងសម្ភារៈ

-

វិក័យប័ត្រសម្ភារៈ Mono-សម្ភារៈ; ផែនការដាក់ស្លាកសម្រាប់កែច្នៃឡើងវិញតាមតំបន់

-

ការប្រកាសដោយគ្មាន PFAS ដែលជាកន្លែងដែលពាក់ព័ន្ធ; ក្រដាស COA និង pH-អព្យាក្រឹតភស្តុតាងសម្រាប់ SKUs បណ្ណសារ

-

កញ្ចប់ភស្តុតាង៖ ការផ្សាភ្ជាប់ការរចនានៃការពិសោធន៍ លក្ខណៈវិនិច្ឆ័យនៃការទទួលយក និងរូបថតសវនកម្ម

សេវាកម្ម និងសុវត្ថិភាព

អ្នកផ្គត់ផ្គង់ម៉ាស៊ីនក្រដាស Glassine

សំណួរគេសួរញឹកញាប់

តើម៉ាស៊ីនផ្ញើក្រដាស Glassine ជាអ្វី?

ខ្សែសង្វាក់ផលិតកម្មពិសេសដែលបង្កើត ផ្សាភ្ជាប់ និងបោះពុម្ពអ្នកផ្ញើសំបុត្រ glassine សម្ភារៈ mono- ផ្តល់នូវរូបរាងពិសេស ការរចនាក្រដាសដែលអាចកែច្នៃឡើងវិញបាន និងដេរជាប់គ្នាក្នុងល្បឿន។

តើ glassine ពិតជាអាចកែច្នៃឡើងវិញបាន និងអាចបំផ្លិចបំផ្លាញបានឬ?

បាទ។ ក្នុងនាមជាផលិតផលក្រដាស កញ្ចក់ស៊ីន ជាធម្មតាចូលទៅក្នុងស្ទ្រីមកែច្នៃក្រដាស ហើយអាចបំបែកបានដោយធម្មជាតិនៅក្រោមលក្ខខណ្ឌសមស្រប។ តម្រឹមការទាមទារជាមួយច្បាប់ក្នុងតំបន់ជានិច្ច។

តើ glassine តម្រូវឱ្យ PFAS ទប់ទល់នឹងជាតិខាញ់ទេ?

លេខ៖ ផ្ទៃក្រាស់ដែលមានរាងដូចប្រតិទិន ផ្តល់នូវភាពធន់នឹងប្រេង និងជាតិខាញ់។ អ្នកទិញជាច្រើននៅតែស្នើសុំការប្រកាសដោយគ្មាន PFAS ដើម្បីសម្រួលដល់ការអនុលោមតាមច្បាប់។

តើអ្នកផ្ញើសំបុត្រ glassine កាត់បន្ថយការគិតថ្លៃ DIM យ៉ាងដូចម្តេច?

ពួកវាមានទំហំខាងស្ដាំបើប្រៀបធៀបទៅនឹងប្រអប់ដែលមានទំហំធំដែលមានឧបករណ៍បំពេញ។ ស្រោមសំបុត្រដែលមានទំហំតូចជាងមុន កាត់បន្ថយការចេញវិក្កយបត្រទម្ងន់បរិមាណ និងធ្វើឱ្យការប្រើប្រាស់គូបកាន់តែប្រសើរឡើង។

តើខ្ញុំគួររំពឹង ROI អ្វីខ្លះ?

ដងថ្លឹងសំខាន់ៗ៖ ការខូចខាតទាប ឌីអឹមអឹមទាប ការកាត់បន្ថយអនុលោមភាពតិចជាង ការផ្លាស់ប្តូរលឿនជាងមុន។ ជាមួយនឹងស្ថេរភាព OEE 12-24 ខែគឺជារឿងធម្មតា អាស្រ័យលើការលាយ SKU និងផ្លូវ។

ឯកសារយោង

-

EcoEnclose • តើ Glassine ជាអ្វី? • ប្លុក EcoEnclose

-

PakFactory • ក្រដាស់កញ្ចក់ • PakFactory Knowledge

-

ការវេចខ្ចប់ JBM • តើ Glassine ជាអ្វី? • ប្លុកវេចខ្ចប់ JBM

-

ការវេចខ្ចប់ JBM • Glassine៖ សម្ភារៈវេចខ្ចប់ប្រកបដោយនិរន្តរភាពសម្រាប់ម៉ាកសម្លៀកបំពាក់ • ការវេចខ្ចប់ JBM

-

គណៈកម្មាការអ៊ឺរ៉ុប • ទិដ្ឋភាពទូទៅនៃការវេចខ្ចប់ និងការវេចខ្ចប់កាកសំណល់ • គណៈកម្មការអឺរ៉ុប

-

Keller & Heckman LLP • បទប្បញ្ញត្តិការវេចខ្ចប់ និងការវេចខ្ចប់កាកសំណល់របស់សហភាពអឺរ៉ុបថ្មី៖ ការរំលេច និងបញ្ហាប្រឈមនៅពេលខាងមុខ • ការបោះពុម្ពផ្សាយ K&H

-

រដ្ឋបាលចំណីអាហារ និងឱសថរបស់សហរដ្ឋអាមេរិក • ដំណាក់កាលចេញនៃភ្នាក់ងារការពារជាតិខាញ់ PFAS ក្នុងការវេចខ្ចប់អាហារ • ការធ្វើបច្ចុប្បន្នភាព FDA

-

រដ្ឋបាលចំណីអាហារ និងឱសថរបស់សហរដ្ឋអាមេរិក • ដំណាក់កាលទីផ្សារចេញនៃសារធាតុការពារជាតិខាញ់ដែលមាន PFAS • ធនធានរបស់ FDA

-

សារព័ត៌មាន Associated Press • រុំ PFAS លែងមានលក់នៅសហរដ្ឋអាមេរិកទៀតហើយ FDA និយាយថា • AP News

-

ក្រុមការវេចខ្ចប់ Amazon • គោលការណ៍ណែនាំអំពីការវេចខ្ចប់គ្មានការខកចិត្ត • ការវេចខ្ចប់ Amazon

-

Stamps.com វិចារណកថា • របៀបគណនាទម្ងន់វិមាត្រ • មគ្គុទ្ទេសក៍ Stamps.com

-

EcoEnclose • Glassine—ការទាមទារដែលអាចកែច្នៃឡើងវិញបាន និងអាចបំបែកបាន • ប្លុក EcoEnclose

ចម្លើយច្បាស់លាស់ចំពោះសំណួរបើក៖

សំណួរ៖ "តើមានការអាប់ដេតមួយណាដែលកាត់បន្ថយការខូចខាត និង DIM ខណៈពេលដែលការពេញចិត្តក្នុងការកែច្នៃឡើងវិញ និងការត្រួតពិនិត្យតាមដាន?"

ចម្លើយ៖ បាទ។ ម៉ាស៊ីន Mailer Paper Glassine ដែលត្រូវបានវិស្វកម្មសម្រាប់ក្រដាស mono-material លក្ខណៈជាក់លាក់ដែលគ្មាន PFAS និងការត្រួតពិនិត្យនៅក្នុងបន្ទាត់ផ្តល់នូវរូបរាងល្អប្រណិតល្អ រក្សាថ្នេរក្នុងល្បឿន កត់ត្រាភស្តុតាងជាបាច់ និងបង្កើនតម្លៃទ្រព្យសម្បត្តិនៃកន្លែងរបស់អ្នក។ ភ្ជាប់ជាមួយម៉ាស៊ីនបត់ក្រដាសសម្រាប់ការបញ្ចូល និងត្រឡប់ អ្នកទទួលបានល្បឿន ភាពធន់ និងការអនុលោមតាមសវនកម្មដែលត្រៀមរួចជាស្រេច ដោយមិនមានការលះបង់សោភ័ណភាព។