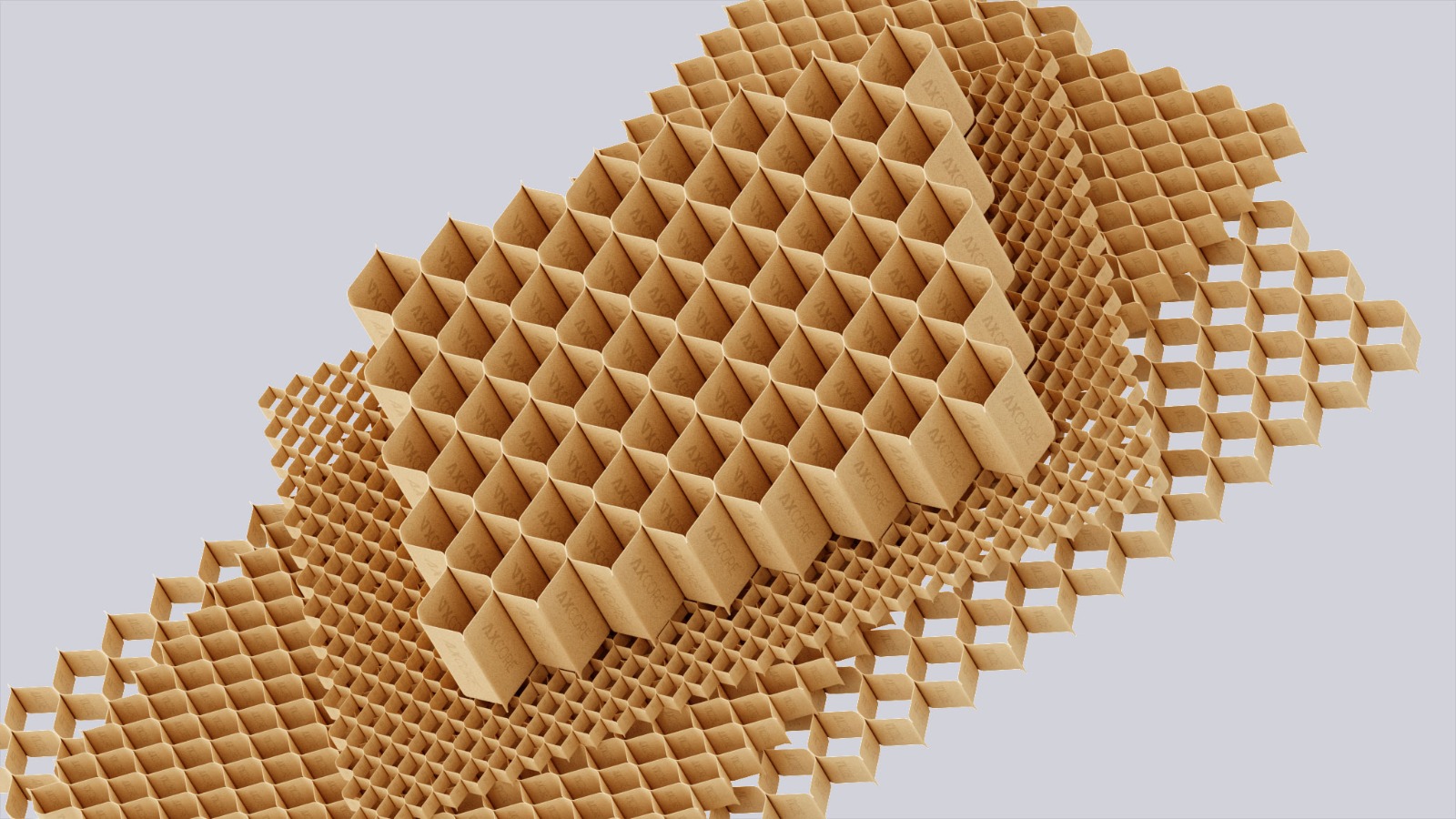

ກະດາດ Honeycomb ທີ່ມີນ້ຳໜັກເບົາ, ແຂງແຮງ ແລະ ສາມາດນຳມາໃຊ້ຄືນໃໝ່ໄດ້, ກຳລັງຫັນປ່ຽນການຫຸ້ມຫໍ່ປ້ອງກັນໂດຍການຕັດຄ່າຂົນສົ່ງ, ຫຼຸດອັດຕາຄວາມເສຍຫາຍ, ແລະ ຫຼຸດຜ່ອນຜົນກະທົບຕໍ່ສິ່ງແວດລ້ອມ.

ເຈ້ຍ Honeycomb

ເຈ້ຍ Honeycomb ໄດ້ເພີ່ມຂຶ້ນໃນຄວາມນິຍົມຍ້ອນວ່າຍີ່ຫໍ້ຊອກຫາການຫຸ້ມຫໍ່ນັ້ນ ຍາກ ກ່ຽວກັບຜົນກະທົບແຕ່ ງ່າຍ ກ່ຽວກັບງົບປະມານແລະດາວເຄາະ. ສ້າງຢູ່ໃນເລຂາຄະນິດດຽວກັນທີ່ໃຫ້ Honeycombs ທໍາມະຊາດມີອັດຕາສ່ວນຄວາມເຂັ້ມແຂງຕໍ່ນ້ໍາຫນັກທີ່ບໍ່ຫນ້າເຊື່ອ, ແກນເຈ້ຍທີ່ສ້າງຂື້ນມານີ້ໃຫ້ຄວາມຕ້ານທານການບີບອັດສູງ, ທົນທານຕໍ່ຄວາມຫນ້າເຊື່ອຖື, ແລະການປົກປ້ອງຫນ້າດິນທີ່ດີເລີດ. ຂ້າງລຸ່ມນີ້, ພວກເຮົາອະທິບາຍວ່າກະດາດ Honeycomb ແມ່ນຫຍັງ, ເປັນຫຍັງມັນມີປະສິດທິພາບດີກວ່າວັດສະດຸທີ່ເປັນມໍລະດົກຫຼາຍ, ແລະວິທີການຜະລິດທີ່ທັນສະໄຫມຈາກການຜະລິດ. ເຄື່ອງຈັກ innopack ເຮັດໃຫ້ມັນສາມາດເຂົ້າເຖິງໄດ້ໃນລະດັບ.

ເຈ້ຍ Honeycomb ແມ່ນຫຍັງ? ເຈ້ຍ Honeycomb ແມ່ນໂຄງສ້າງຂອງເຈ້ຍປະກອບດ້ວຍແກນ hexagonal sandwiched ລະຫວ່າງແຜ່ນ liner ແປ. ເຊລຫົກຫລ່ຽມແຈກຢາຍການໂຫຼດໄດ້ເທົ່າທຽມກັນ—ຄືກັບເສັ້ນໄຍ I-beam—ສ້າງແຜງທີ່ມີຄວາມສະຫວ່າງທີ່ສຸດແຕ່ມີຄວາມແຂງແກ່ນຢ່າງໂດດເດັ່ນ. ມັນມັກຈະເຮັດຈາກກະດາດກະດາດກະດາດແລະກາວທີ່ມີນ້ໍາ, ຫຼັງຈາກນັ້ນປ່ຽນເປັນແຜ່ນ, ກະດານ, ແຜ່ນປ້ອງກັນຂອບ, ແຜ່ນທີ່ບໍ່ມີຊ່ອງຫວ່າງ, ຫຼືແຜ່ນຫໍ່. ເນື່ອງຈາກວ່າມັນເປັນເຈ້ຍ, ມັນໄດ້ຖືກນໍາມາໃຊ້ຄືນຢ່າງກວ້າງຂວາງໃນກະດາດທີ່ມີຢູ່ແລະສາມາດເອົາມາຈາກເນື້ອຫາທີ່ຖືກນໍາມາໃຊ້ໃຫມ່ສູງ.

ເລຂາຄະນິດຫຼັກ: ຈຸລັງ hexagonal ຂະຫຍາຍອອກເປັນ matrix ຄົງທີ່, ດູດຊ໊ອກ.ເສັ້ນ: ຫນຶ່ງຫຼືສອງດ້ານທີ່ປະເຊີນຫນ້າກັບຮາບພຽງຢູ່ກັບແກນເພື່ອສ້າງແຜ່ນຫຼືກະດານທີ່ມີຄວາມເຂັ້ມແຂງບີບອັດທີ່ດີເລີດ.ຮູບແບບ: ມ້ວນ, ພັບພັດລົມ, ແຜ່ນຕັດຕັດ, ກອງມຸມ / ຂອບ, ແລະກະດານຂະຫນາດທີ່ກໍາຫນົດເອງສໍາລັບ pallets ຫຼື cartons. ຜົນໄດ້ຮັບແມ່ນອຸປະກອນປ້ອງກັນທີ່ຫລາກຫລາຍທີ່ປ່ຽນແທນການແກ້ໄຂໄມ້ແລະພາດສະຕິກທີ່ຫນັກກວ່າໃນຂະນະທີ່ການຮັກສາຜະລິດຕະພັນໃຫ້ປອດໄພຜ່ານການເກັບຮັກສາ, ການຈັດການແລະການຂົນສົ່ງ.

ຜົນປະໂຫຍດທີ່ສໍາຄັນຂອງເຈ້ຍ Honeycomb ໃນການຂົນສົ່ງ ອັດຕາສ່ວນຄວາມແຮງຕໍ່ນ້ຳໜັກສູງ: ສະຫນອງການບີບອັດທີ່ເຂັ້ມແຂງແລະຄວາມເຂັ້ມແຂງ stacking ໂດຍບໍ່ມີການມະຫາຊົນຂອງໄມ້ຫຼືໂຟມຫນາແຫນ້ນ.ການຂົນສົ່ງທີ່ປະຫຍັດຄ່າໃຊ້ຈ່າຍ: ນ້ ຳ ໜັກ ວັດສະດຸທີ່ຕໍ່າລົງຊ່ວຍຫຼຸດນ້ ຳ ໜັກ ມິຕິແລະນ້ ຳ ມັນເຊື້ອໄຟໃນທົ່ວການຂົນສົ່ງ parcel ແລະ LTL / FTL.ການຫຼຸດຜ່ອນຄວາມເສຍຫາຍ: ຫຼັກ hex ດູດຊຶມແຮງສັ່ນສະເທືອນແລະກະຈາຍພະລັງງານຜົນກະທົບ, ປົກປ້ອງມຸມແລະພື້ນຜິວຮາບພຽງ.ຄວາມຍືນຍົງ: ເຈ້ຍ, ສາມາດເອົາມາໃຊ້ຄືນໃໝ່ໄດ້, ມັກຈະເຮັດດ້ວຍເສັ້ນໃຍທີ່ນຳມາໃຊ້ໃໝ່ ແລະ ລະບົບກາວທີ່ໃຊ້ນ້ຳ.ການປັບແຕ່ງ: ຂະໜາດຂອງເຊລ, ເກຣດກະດາດ, ຄວາມໜາ, ແລະຂະໜາດແຜງສາມາດປັບໄດ້ສຳລັບ SKUs ທີ່ແຕກຕ່າງກັນ ແລະຄວາມຕ້ອງການເລື່ອນ/ stack.ເປັນມິດກັບແຮງງານ: ເຮັດຄວາມສະອາດເພື່ອຕັດ, ຮູບຮ່າງ, ແລະຖິ້ມ - ບໍ່ມີລູກປັດທີ່ແຕກຫັກ, ການຍຶດຕິດຄົງທີ່, ຫຼືແຄມແຫຼມ. ເປັນຫຍັງຕ້ອງເລືອກເຈ້ຍ Honeycomb ຫຼາຍກວ່າການຫຸ້ມຫໍ່ແບບດັ້ງເດີມ? ເງື່ອນໄຂ ເຈ້ຍ Honeycomb ຟອງ/ຖົ່ວດິນ Foam/Plastic Inserts ໄມ້/OSB ການປົກປ້ອງ ການປົກປ້ອງດ້ານທີ່ດີເລີດ & ຂອບ; stacking ທີ່ເຂັ້ມແຂງ ການຕື່ມ void ດີ; ອ່ອນກວ່າສໍາລັບການ stacking / ຂອບ ເບາະສູງ; ສາມາດ overkill ສໍາລັບ SKUs ຫຼາຍ ແຂງແຮງຫຼາຍ; ໜັກ ແລະມີວັດສະດຸຫຼາຍ ນ້ຳໜັກ ແສງສະຫວ່າງສູງສຸດ ແສງສະຫວ່າງ ຂະຫນາດກາງ ໜັກ ຄວາມຍືນຍົງ ເຈ້ຍ; ສາມາດຣີໄຊເຄິນໄດ້ຢ່າງກວ້າງຂວາງ ພາດສະຕິກ; ການລີໄຊເຄີນແບບຈຳກັດໃນພາກປະຕິບັດ ພາດສະຕິກ/ໂຟມ; ສິ່ງທ້າທາຍສຸດທ້າຍຂອງຊີວິດ ໄມ້; ໃຊ້ຄືນໄດ້ ແຕ່ໃຊ້ຊັບພະຍາກອນຫຼາຍ ຄ່າໃຊ້ຈ່າຍເພື່ອປົກປ້ອງ ມູນຄ່າສູງ; ສິ່ງເສດເຫຼືອໜ້ອຍລົງ ແລະ ເຮັດວຽກຄືນໃໝ່ ຄ່າໃຊ້ຈ່າຍຕໍ່ຫນ່ວຍຕ່ໍາ; ອາດຈະຕ້ອງການ dunnage ພິເສດ ຄ່າໃຊ້ຈ່າຍທີ່ສູງຂຶ້ນ; ເຄື່ອງມືທີ່ຊັດເຈນ ຄ່າຂົນສົ່ງ ແລະການຂົນສົ່ງທີ່ສູງຂຶ້ນ ຄວາມສາມາດໃນການຂະຫຍາຍ ງ່າຍທີ່ຈະປ່ຽນ, ຕັດຕາຍ, ແລະຂະຫນາດທີ່ເຫມາະສົມ ມີຢ່າງກວ້າງຂວາງ; ການປະຕິບັດທີ່ບໍ່ສອດຄ່ອງ ຕ້ອງການ molds / ເຄື່ອງມື; ຊ້າກວ່າທີ່ຈະເຮັດຊ້ຳ ຊ່າງໄມ້ & ຄວາມຕ້ອງການເກັບຮັກສາ; ການປ່ຽນແປງຊ້າ

ຖ້າເປົ້າຫມາຍຂອງທ່ານແມ່ນເພື່ອຫຼຸດຄ່າໃຊ້ຈ່າຍທັງຫມົດໃນຫນ້າດິນໃນຂະນະທີ່ປັບປຸງຄວາມຍືນຍົງ, ເຈ້ຍ Honeycomb ມັກຈະຊະນະການວັດແທກລວມຂອງການປົກປ້ອງ, ນ້ໍາຫນັກ, ແລະການນໍາມາໃຊ້ຄືນໃຫມ່. ມັນແຂງແຮງພໍທີ່ຈະວາງຊ້ອນກັນໄດ້, ອ່ອນໂຍນພຽງພໍສໍາລັບພື້ນຜິວສໍາເລັດຮູບ, ແລະສາມາດກໍານົດໄດ້ສໍາລັບທຸກສິ່ງທຸກຢ່າງຈາກເຄື່ອງເອເລັກໂຕຣນິກແບບຮາບພຽງໄປຫາເຟີນີເຈີແລະຊິ້ນສ່ວນລົດໃຫຍ່.

ຄໍາແນະນໍາການຈັດຕັ້ງປະຕິບັດສໍາລັບຜົນໄດ້ຮັບທີ່ດີກວ່າ ຈັບຄູ່ cell ແລະ caliper ກັບວຽກ: ຈຸລັງຂະຫນາດໃຫຍ່ແລະ calipers ຫນາເພີ່ມ cushioning ແລະ stack ຄວາມເຂັ້ມແຂງ; ຈຸລັງຂະຫນາດນ້ອຍປັບປຸງຄວາມລຽບຂອງພື້ນຜິວ.ວິສະວະກອນ "ລະບົບ": ຜະສົມຜະສານຜ້າອັດປາກມົດລູກດ້ວຍກອງມຸມ/ຂອບ ແລະກ່ອງຂະໜາດຂວາເພື່ອປ້ອງກັນການຕົກຄ້າງ ແລະຄວາມເສຍຫາຍດ້ານຂ້າງ.ຂະຫນາດຂວາຢ່າງຮຸນແຮງ: ແທນທີ່ປຼາສະຕິກທີ່ວ່າງອອກດ້ວຍແຜ່ນຕັດໃຫ້ພໍດີທີ່ຫຼຸດກ້ອນ ແລະ ປັບປຸງຄວາມໜາແໜ້ນຂອງການໂຫຼດ.ຢືນຢັນດ້ວຍການທົດສອບ: ດໍາເນີນການຈໍາລອງການຫຼຸດລົງ/ stack/transport ເພື່ອໂທຫາໃນ spec ເບົາທີ່ສຸດທີ່ຍັງບັນລຸເປົ້າຫມາຍການປະຕິບັດ. ຈາກ Prototype ກັບ Scale: Honeycomb Paper Production ດ້ວຍເຄື່ອງຈັກ innopack ເພື່ອປົດລັອກມູນຄ່າອັນເຕັມທີ່ຂອງ Honeycomb, ທ່ານຕ້ອງການການແປງທີ່ມີຄວາມຫນ້າເຊື່ອຖື, ສູງ. ຢູ່ທີ່ນັ້ນ ເຄື່ອງຈັກ innopack ເຄື່ອງຈັກເຈ້ຍ Honeycomb ຂອງພວກເຂົາປັບປຸງຂະບວນການທັງຫມົດ - ຈາກການຂະຫຍາຍຫຼັກແລະການນໍາໃຊ້ກາວກັບການເຄືອບ, ການຕັດ, ແລະການຕັດຕາຍ - ດັ່ງນັ້ນທີມງານຫຸ້ມຫໍ່ສາມາດຍ້າຍຈາກການທົດລອງໄປສູ່ການຜະລິດໂດຍບໍ່ມີຂໍ້ບົກພ່ອງ.

ຄວາມໄວ & ຄວາມສອດຄ່ອງ: ການຈັດການເວັບໄຊຕ໌ອັດຕະໂນມັດແລະການຄວບຄຸມກາວທີ່ຊັດເຈນສົ່ງຈຸລັງແລະພັນທະບັດທີ່ເປັນເອກະພາບໃນລະດັບ.ຂໍ້ມູນຈໍາເພາະແບບຍືດຫຍຸ່ນ: ກຳນົດຄ່າຂະໜາດເຊວ, ເກຣດເຈ້ຍ, ຄວາມໜາ, ແລະຂະໜາດຂອງແຜ່ນໃຫ້ກົງກັບຄວາມຕ້ອງການຂອງ SKU.ຂີ້ເຫຍື້ອຕ່ໍາ: ການຕັດທີ່ເໝາະສົມ ແລະຄວາມໄວຂອງສາຍທີ່ໝັ້ນຄົງຈະຫຼຸດການສູນເສຍການຕັດ ແລະເຮັດວຽກຄືນໃໝ່.ກຽມພ້ອມສໍາລັບການຂະຫຍາຍຕົວ: ເສັ້ນໂມດູນຂະຫຍາຍອອກເມື່ອປະລິມານເພີ່ມຂຶ້ນ, ຮັກສາຄ່າໃຊ້ຈ່າຍຕໍ່ຫົວໜ່ວຍແຂ່ງຂັນ. ບໍ່ວ່າທ່ານຈະປ່ຽນໂຟມດ້ວຍເຈ້ຍຫຼືການລິເລີ່ມເສດຖະກິດວົງວຽນໃນທົ່ວເຄືອຂ່າຍຂອງທ່ານ, ເຄື່ອງຈັກ innopack ສະໜອງເຄື່ອງຈັກເຈ້ຍ Honeycomb ເພື່ອຜະລິດແຜງ ແລະແຜ່ນຮອງຄຸນນະພາບຢ່າງວ່ອງໄວ—ຕອບສະໜອງໄດ້ກຳນົດເວລາອັນເຄັ່ງຄັດ ແລະເປົ້າໝາຍຄວາມຍືນຍົງ ໃນຂະນະທີ່ປົກປ້ອງຜະລິດຕະພັນຂອງທ່ານໃນການຂົນສົ່ງ.