လေကူရှင်ထုပ်ပိုးမှုတွင် ပေါ့ပါးသော၊ တုန်ခါမှုစုပ်ယူနိုင်သော၊ နေရာလွတ်ချွေတာပြီး စွန့်ပစ်ပစ္စည်းများကို ဖြတ်တောက်ရန်အတွက် လိုအပ်ချက်အရ ထုတ်လုပ်ထားသော ကုန်ပစ္စည်းများကို သယ်ယူပို့ဆောင်ရာတွင် လုံခြုံစေရန်အတွက် လေကူရှင်များ ဖောင်းပွသောဖလင်ခေါင်းအုံးများကို အသုံးပြုသည်။

လေကူရှင်ထုပ်ပိုးမှုတွင် ပေါ့ပါးသော၊ တုန်ခါမှုစုပ်ယူနိုင်သော၊ နေရာလွတ်ချွေတာပြီး စွန့်ပစ်ပစ္စည်းများကို ဖြတ်တောက်ရန်အတွက် လိုအပ်ချက်အရ ထုတ်လုပ်ထားသော ကုန်ပစ္စည်းများကို သယ်ယူပို့ဆောင်ရာတွင် လုံခြုံစေရန်အတွက် လေကူရှင်များ ဖောင်းပွသောဖလင်ခေါင်းအုံးများကို အသုံးပြုသည်။

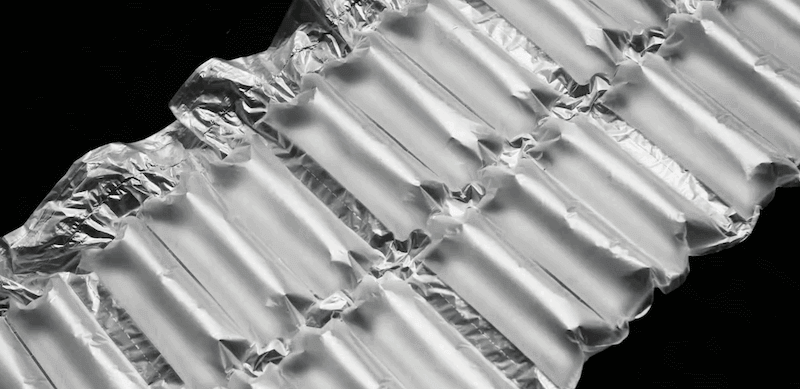

ထုပ်ပိုးမှုအတွက် Air Cushion

“ထုပ်ပိုးမှုအတွက် လေကူရှင်” ဆိုတာ ဘာလဲ?

ထုပ်ပိုးမှုအတွက် Air Cushion ကွက်လပ်များ၊ ဘောင်ခတ်ထားသောထောင့်များနှင့် သင်္ဘောပုံးအတွင်းမှ တုန်လှုပ်မှုကို စုပ်ယူပေးသည့် ဖောင်းကားနေသော ဖလင်ခေါင်းအုံးများနှင့် စောင်ပြားအကွာအဝေးကို ရည်ညွှန်းသည်။ ကြိုတင်ဖွဲ့စည်းထားသော အမြှုပ်များ သို့မဟုတ် ရိုးရာပူဖောင်းထုပ်များနှင့် မတူဘဲ၊ လေကူရှင်များကို ထုပ်ပိုးသည့်နေရာရှိ ပြားချပ်ချပ်ရုပ်ရှင်မှ ဖန်တီးထားပြီး တိကျသောဖိအားသို့ ဖောင်းပွလာပြီး အလုံပိတ်ဖြစ်သည်။ ပစ္စည်းများကို ကျစ်ကျစ်လျစ်လျစ်သော အလိပ်များအဖြစ် သင်္ဘောဖြင့် တင်ပို့ရောင်းချသောကြောင့် အမှတ်တံဆိပ်များသည် သိုလှောင်ရုံနေရာနှင့် ထုထည်ကြီးမားသော အမှိုက်ပုံနှင့်ဆက်စပ်သော ကုန်စည်ပို့ဆောင်ရေးစရိတ်များကို သိသိသာသာ လျှော့ချပေးချိန်တွင် အမှတ်တံဆိပ်များသည် ကောင်းမွန်သောအကာအကွယ်ကို ရရှိပါသည်။

လေကူရှင်များသည် ပုံစံမျိုးစုံဖြင့် လာပါသည်- ခေါင်းအုံးတစ်လုံးတည်း ပျက်ပြယ်ဖြည့်စွက်ဖျာခင်း၊ မျက်နှာပြင်ကာကွယ်မှုနှင့် tube/ edge profile များအတွက် ထောင့်ညှပ်ခြင်း။. အော်ပရေတာများသည် ထုတ်ကုန်၏ ပျက်စီးလွယ်မှုနှင့် ပုံးပုံး၏ ဂျီဩမေတြီနှင့် ကိုက်ညီရန် ပုံစံ၊ အရွယ်အစားနှင့် ဖြည့်စွက်မှုအဆင့်ကို ရွေးချယ်သည်။

Air Cushion Packaging ၏ အဓိက အားသာချက်များ

- အလေးချိန်နည်းချိန်တွင် ပိုမိုကောင်းမွန်သော အကာအကွယ် ဖောင်းနေသောအခန်းများသည် ပါဆယ်များထဲသို့ လေးလံသောဒြပ်ထုကို မထည့်ဘဲ သက်ရောက်မှုစွမ်းအင်ကို စွန့်ထုတ်ပြီး ဖိသိပ်မှုကို ခုခံသည်။

- လိုအပ်သလောက် ထုတ်လုပ်ခြင်း- ထုပ်ပိုးချိန်၌ သင်လိုအပ်သောအရာကို အတိအကျဖန်တီးပါ—ကြီးမားသောပစ္စည်းများကို မှာယူခြင်း သို့မဟုတ် အလယ်အလတ်အချိန်ကုန်သွားခြင်း မရှိတော့ပါ။

- နေရာနှင့် ကုန်တင်ချွေတာခြင်း- Flat film rolls များ ထူထပ်စွာ သိုလှောင်; လိပ်တစ်ခုသည် အမြှုပ်များ သို့မဟုတ် ပူဖောင်းထုပ်များကို အစားထိုးနိုင်သည်။

- တသမတ်တည်း၊ ပရော်ဖက်ရှင်နယ် unboxing- သန့်ရှင်းပြီး ဖောက်ထွင်းမြင်ရသော ခေါင်းအုံးများသည် ကုန်ပစ္စည်းများကို သပ်သပ်ရပ်ရပ် တင်ဆက်ပြီး အညစ်အကြေးများနှင့် လျော့ရဲနေသော ဖြည့်စွက်စာများကို လျှော့ချပေးသည်။

- လည်ပတ်မှုမြန်နှုန်း- အလိုအလျောက်စနစ်များသည် လျင်မြန်စွာ ရွေ့လျားနေသော ရွေး/ထုပ်လိုင်းများကို ပံ့ပိုးပေးသည့် မြင့်မားသော ဖောက်ထွက်အားတွင် ဖောင်းပွပြီး တံဆိပ်ခတ်ထားသည်။

- ရေရှည်တည်တံ့မှု ရွေးချယ်စရာများ- ရုပ်ရှင်များကို ပြန်လည်အသုံးပြုထားသော အကြောင်းအရာ၊ ပိုမိုပါးလွှာသော တိုင်းတာမှုများ၊ သို့မဟုတ် ပြန်လည်အသုံးပြုနိုင်သော အစေးများဖြင့် ရရှိနိုင်ပါသည်။ on-demand output သည်လည်း အလွန်အကျွံသုံးစွဲမှုကို လျှော့ချပေးသည်။

ဘယ်စက်မှုလုပ်ငန်းက Air Cushions ကိုသုံးလဲ။

- E-commerce နှင့် 3PL များ- ပြောင်းလဲနိုင်သော ကတ်တလောက်အရွယ်အစားများအတွက် စွယ်စုံသုံး ဖြည့်စွက် peak-season ramp-ups အတွက် စံပြ

- လူသုံးလျှပ်စစ်ပစ္စည်း- သိမ်မွေ့သော စက်ပစ္စည်းများနှင့် ဆက်စပ်ပစ္စည်းများကို တုန်ခါမှုနှင့် ထောင့်ပြုတ်ကျခြင်းမှ ကာကွယ်ပေးသည်။

- အလှအပနှင့် တစ်ကိုယ်ရေ စောင့်ရှောက်မှု- ပရီမီယံတင်ဆက်မှုကို ထိန်းသိမ်းထားစဉ်တွင် ပွတ်တိုက်မှုနှင့် ယိုစိမ့်မှုကို ကာကွယ်ပေးသည်။

- အိမ်သုံးပစ္စည်းနှင့် အသေးစားအသုံးအဆောင်များ ပုံသဏ္ဍာန်မမှန်သောပုံသဏ္ဍာန်များနှင့် လေးလံသောအစိတ်အပိုင်းများကို quilted pads ဖြင့်တည်ငြိမ်စေသည်။

- ဆေးဝါး/ကျန်းမာရေး ထုတ်ကုန်များ လိုက်လျောညီထွေရှိသော ထုပ်ပိုးမှုပတ်ဝန်းကျင်အတွက် သန့်ရှင်းပြီး ဖုန်ကင်းသောကူရှင်များ။

- မော်တော်ကားနှင့် စက်မှုသုံးအပိုပစ္စည်းများ- အားဖြည့်ခေါင်းအုံးရုပ်ရှင်များဖြင့် ချွန်ထက်သော သို့မဟုတ် သိပ်သည်းသော အစိတ်အပိုင်းများကို ချည်နှောင်ပါ။

Air Cushions များကို ဘယ်လိုဖန်တီးသလဲ (Production Workflow)

လေကူရှင်များကို အထူးထုတ်လုပ်ထားသော ရုပ်ရှင်များဖြစ်သည့် သီးသန့် converting ကိရိယာများကို အသုံးပြုထားသည်။ ပလပ်စတစ်လေထုခေါင်းအုံးလုပ်စက်. လုပ်ငန်းစဉ်သည် ပုံမှန်အားဖြင့် ဤအဆင့်များကို လိုက်နာသည်-

- ရုပ်ရှင်ကို ပြန်ဖွင့်သည်- ကြိုတင်ရိုက်နှိပ်ထားသော၊ ကြိုတင်ဖောက်ထားသော သို့မဟုတ် တောက်ပြောင်သောလိပ်သည် တိကျသောဝဘ်တင်းမာမှုဖြင့် စက်ထဲသို့ ဖြည့်သွင်းသည်။

- ငွေကြေးဖောင်းပွမှု- ချိန်ညှိထားသော လေမော်ဂျူးသည် အခန်းတစ်ခုစီကို ပစ်မှတ်ထားရန် ဖိအားဖြည့်ပေးကာ ထပ်ခါတလဲလဲလုပ်နိုင်သော ကူရှင်အမြင့်ကို သေချာစေသည်။

- အပူပိတ်ခြင်း- အလုံပိတ်အကန့်များသည် လေထဲတွင်သော့ခတ်ရန်၊ ခိုင်ခံ့သောချုပ်ရိုးများဖြင့် ခေါင်းအုံးများပြုလုပ်ထားသော သို့မဟုတ် ဂွမ်းစပုံစံများပြုလုပ်ရန် လမ်းကြောင်းများကို ဂဟေဆက်သည်။

- အပေါက်ဖောက်ခြင်း ထိန်းချုပ်ခြင်း- ဘူတာရုံ ergonomics နှင့် ကိုက်ညီစေရန် လွယ်ကူသော မျက်ရည်ဖောက်ပေါက်များ သို့မဟုတ် ဖြတ်တောက်ထားသော အရှည်များကို ဖန်တီးထားသည်။

- အရည်အသွေးစစ်ဆေးမှုများ ယိုစိမ့်မှု ထောက်လှမ်းခြင်း၊ တံဆိပ် ခိုင်ခံ့မှု စစ်ဆေးခြင်း နှင့် လေစီးဆင်းမှု ချိန်ညှိခြင်းတို့သည် ညီညွတ်မှုကို ထိန်းသိမ်းထားသည်။

ရလဒ်မှာ သေတ္တာတစ်ခုစီနှင့် အံဝင်ခွင်ကျရှိသော အဆင်သင့်အသုံးပြုနိုင်သော ခေါင်းအုံးများစီးကြောင်းတစ်ခုဖြစ်ပြီး အမှိုက်များကို နည်းပါးစေပြီး အကာအကွယ်စွမ်းဆောင်ရည်ကို အမြင့်ဆုံးဖြစ်စေပါသည်။

Air Cushions နှင့် ရိုးရာရွေးချယ်မှုများ

| ထူးခြားချက် | လေ နားလည်မှုတွေ | Bubble Wrap | Loose Fill (မြေပဲ) |

| သိုလှောင်မှု စွမ်းဆောင်ရည် | အထူးကောင်းမွန်သော (ပြားချပ်ချပ်များ) | အလယ်အလတ် (ကြီးမားသောလိပ်များ) | ညံ့ (အိတ်ကြီး/ပုံး) |

| Pack Speed | အလိုအလျောက်လေထိုးတံဖြင့် မြင့်သည်။ | တော်ရုံတန်ရုံ | မြန်ပေမယ့် ရှုပ်တယ်။ |

| တင်ပြခြင်း။ | သန့်ရှင်းပြီး ပရီမီယံအသွင်အပြင် | လက်ခံပါတယ်။ | ရှုတ်; ရွှေ့ပြောင်းသွားလာမှု |

| အကာအကွယ်/အလေးချိန်အချိုး | မြင့်မားသောဖိအား (tunable pressure) | တော်ရုံတန်ရုံ | ပြောင်းလဲနိုင်သော၊ ပြောင်းရွှေ့အန္တရာယ် |

| အမှိုက်လျှော့ချရေး | ခိုင်မာသော (လိုအပ်သလောက်) | တော်ရုံတန်ရုံ | နိမ့်သည်။ |

ရွေးချယ်မှု အကြံပြုချက်များ- အကောင်းဆုံးရလဒ်များ ရယူခြင်း။

- ထုတ်ကုန်နှင့် ပုံစံကို ကိုက်ညီသည်- ပျက်ပြယ်သောဖြည့်စွက်မှုအတွက်တစ်ခုတည်းခေါင်းအုံး; မျက်နှာပြင်ကာကွယ်ရေးအတွက် quilted pads; အစွန်းများအတွက် ပြွန်ပရိုဖိုင်များ။

- ငွေဖောင်းပွမှုကို ညှိပါ- တုန်ခါမှုစုပ်ယူမှုအတွက် အနည်းငယ်နိမ့်သောဖိအားသည် လွန်ကဲသည်။ မြင့်မားသောဖိအားသည် အရာဝတ္ထုများကို သော့ခတ်သည်။

- ပုံးကို ညာဘက်အရွယ်အစား- အပျက်အစီးများကို လျှော့ချရန်နှင့် အမှိုက်ပုံးကို အလွန်အကျွံအသုံးပြုရန် သင့်လျော်သောအရွယ်အစားသေတ္တာဖြင့် စတင်ပါ။

- ရုပ်ရှင်ရွေးချယ်မှု- အထူ၊ ပြန်လည်အသုံးပြုထားသော အကြောင်းအရာနှင့် ထုတ်ကုန်အလေးချိန်နှင့် အနားသတ်များနှင့် ဆက်စပ်နေသော ထိုးဖေါက်မှုခံနိုင်ရည်ကို ထည့်သွင်းစဉ်းစားပါ။

- Ergonomics- inflator ကို လက်တစ်ကမ်းအကွာတွင် နေရာချပါ။ ထပ်တလဲလဲ အထုပ်အပိုးများကို အရှိန်မြှင့်ရန် အကြိုမျက်ရည် အရှည်များ။

အရည်အသွေးနှင့် ရေရှည်တည်တံ့မှုဆိုင်ရာ ထည့်သွင်းစဉ်းစားမှုများ

တစ်သမတ်တည်း စွမ်းဆောင်နိုင်စေရန် တံဆိပ်တုံးများ၏ ကြံ့ခိုင်မှု၊ ယိုစိမ့်မှုနှုန်းနှင့် ကူရှင်အမြင့်များကို အချိန်အခါအလိုက် စစ်ဆေးမှုများ ပြုလုပ်ပါ။ ရေရှည်တည်တံ့မှုပန်းတိုင်များအတွက်၊ ပိုပါးလွှာသော စွမ်းအားမြင့်ရုပ်ရှင်များကို အသုံးပြုပါ၊ ဖြစ်နိုင်သည့်နေရာတွင် ပြန်လည်အသုံးပြုထားသော အကြောင်းအရာကို သတ်မှတ်ပေးပြီး အရွယ်အစားမှန်ကန်စေရန် အဖွဲ့များကို လေ့ကျင့်ပေးပါ။ ကူရှင်များကို ဝယ်လိုအားအရ ထုတ်လုပ်သောကြောင့်၊ ထုပ်ပိုးမှုခြေရာများ—နှင့်ဆက်စပ်သော သယ်ယူပို့ဆောင်ရေးထုတ်လွှတ်မှု—တို့သည် သယ်ယူပို့ဆောင်ရေးတွင် ထူထပ်သောဒုတ်ကျင်းများနှင့် ကျဆင်းသွားသောကြောင့်ဖြစ်သည်။

အမြဲမေးလေ့ရှိသောမေးခွန်းများ

လေကူရှင်များကို ပြန်လည်အသုံးပြုနိုင်ပါသလား။

ရုပ်ရှင်အများအပြားကို သတ်မှတ်ထားသော စမ်းချောင်းများတွင် ပြန်လည်အသုံးပြုနိုင်သည် (ဒေသခံလမ်းညွှန်ချက်များကို စစ်ဆေးပါ)။ ရရှိနိုင်သောနေရာတွင် သင့်လျော်သောစုစည်းမှုတွင် ရုပ်ရှင်ကို မကျေမနပ်ဖြစ်ကာ စွန့်ပစ်ပါ။

ပို့ဆောင်နေစဉ်အတွင်း လေကူရှင်များ ပေါက်ထွက်မလား။

အရည်အသွေး တံဆိပ်များနှင့် မှန်ကန်စွာ ချိန်ညှိထားသော ဖိအားများသည် ပုံမှန် compression နှင့် drops များကို ခံနိုင်ရည်ရှိသည်။ လေးလံသော သို့မဟုတ် ချွန်ထက်သော အရာများအတွက်၊ အားဖြည့်ထားသော ရုပ်ရှင်များကို ရွေးချယ်ပြီး အစွန်းများကို အကာအကွယ်ထည့်ပါ။

လေကူရှင်များသည် ထုပ်ပိုးမှုအားလုံးကို အစားထိုးပါသလား။

၎င်းတို့သည် ညာဘက်အရွယ်အစားပုံးများကို ဖြည့်စွက်ပြီး လိုအပ်သည့်အခါတွင် အပိုပံ့ပိုးမှုများ (ပိုင်းခြားခြင်း၊ ထောင့်အကာများ)။ ရည်ရွယ်ချက်မှာ ထုတ်ကုန်ကို တည်ငြိမ်စေပြီး တုန်လှုပ်မှုကို ထိရောက်စွာ စုပ်ယူရန်ဖြစ်သည်။

နိဂုံး

ထုပ်ပိုးမှုအတွက် Air Cushion ခေတ်မီပြည့်စုံမှုအတွက် ပေါ့ပါးသောကာကွယ်မှု၊ မြန်နှုန်းနှင့် အာကာသထိရောက်မှုတို့ကို ပေါင်းစပ်ထားသည်။ ကူရှင်များကို စိတ်ချယုံကြည်စွာဖြင့် မှာယူထုတ်လုပ်ပေးပါသည်။ ပလပ်စတစ်လေထုခေါင်းအုံးလုပ်စက်အမှတ်တံဆိပ်များသည် စွန့်ပစ်ပစ္စည်းများကို လျှော့ချနိုင်သည်၊ ထုပ်ပိုးခြင်းကို မြှင့်တင်နိုင်ပြီး အမျိုးမျိုးသောစက်မှုလုပ်ငန်း—အီလက်ထရွန်းနစ်မှ အလှကုန်အထိ—စက်မှုလုပ်ငန်းသုံးပစ္စည်းများအထိ—လည်ပတ်မှုသွက်လက်မြန်ဆန်ပြီး ကုန်ကျစရိတ်များကို ထိန်းချုပ်ထားစဉ်တွင် ထုတ်ကုန်များကို ကာကွယ်နိုင်သည်။