ପ୍ଲାଷ୍ଟିକ୍ ପ୍ୟାକେଜିଂ ମେସିନ୍ ସହିତ ଆପଣଙ୍କର ଲାଇନକୁ ଶକ୍ତି ଦିଅନ୍ତୁ ଯାହା ଗତି, ସ୍ଥାୟୀତ୍ୱ ଏବଂ ପୁନ y ବ୍ୟବହାର ଯୋଗ୍ୟ ଫର୍ମାଟ୍ ବିତରଣ କରେ | ଇନୋପ୍ୟାକ୍ ର ଏୟାର ତକିଆ, ଏୟାର ସ୍ତମ୍ଭ ଏବଂ ଏୟାର ବବୁଲ ସିଷ୍ଟମ କ୍ଷତି ହ୍ରାସ କରେ, PCR ଚଳଚ୍ଚିତ୍ରକୁ ସମର୍ଥନ କରେ ଏବଂ ଅଡିଟ୍-ପ୍ରସ୍ତୁତ ତଥ୍ୟ ସହିତ ବିଶ୍ global ର EPR ନିୟମ ପୂରଣ କରିବାରେ ସାହାଯ୍ୟ କରେ |

ଓପ୍ସ ମ୍ୟାନେଜର: "ଆମକୁ କ୍ଷତି ହାର ହ୍ରାସ କରିବାକୁ, ନୂତନ EPR ନିୟମ ପୂରଣ କରିବାକୁ ଏବଂ 20% ଶୀଘ୍ର ପଠାଇବାକୁ ପଡିବ। ଗୋଟିଏ ଲିଭର ଅଛି ଯାହା ତିନୋଟି ହିଟ୍ କରେ?"

ପ୍ୟାକେଜିଂ ଇଞ୍ଜିନିୟର: “ହଁ - ଲାଇନକୁ ଅପଗ୍ରେଡ୍ କରନ୍ତୁ | ଏୟାର ତକିଆ / ଏୟାର ସ୍ତମ୍ଭ / ଏୟାର ବବୁଲ ସହିତ ପ୍ଲାଷ୍ଟିକ୍ ପ୍ୟାକେଜିଂ ଯନ୍ତ୍ର। ଏହା ଦ୍ରୁତ, ସ୍ଥାୟୀ, ଅଡିଟ୍-ପ୍ରସ୍ତୁତ |”

ଅପ୍ସ ମ୍ୟାନେଜର୍: “ମୋତେ ନମ୍ବର ଦେଖାନ୍ତୁ ଏବଂ କ’ଣ କିଣିବି |”

ପ୍ୟାକେଜିଂ ଇଞ୍ଜିନିୟର: “ଆମେ ବିକଳ୍ପଗୁଡିକ ତୁଳନା କରିବୁ, ଏକ ROI ଚଳାଇବୁ, ଏବଂ ଇନୋପ୍ୟାକ୍ ମେସିନାରୀରୁ ନିର୍ଦ୍ଦିଷ୍ଟ ମେସିନ୍ - ସେମାନେ ଏଣ୍ଡ-ଟୁ-ଏଣ୍ଡ ସିଷ୍ଟମ ଏବଂ ସ୍ପେୟାର ପାଇଛନ୍ତି। ପ୍ରସ୍ତୁତ?”

ଅପ୍ସ ମ୍ୟାନେଜର୍: “ଚାଲ ଏହା କରିବା |”

ଏହି ଗାଇଡ୍ କ’ଣ କଭର୍ କରେ |

ପ୍ଲାଷ୍ଟିକ୍ ପ୍ୟାକେଜିଂ ଯନ୍ତ୍ର କାହିଁକି 2025 ରେ ଜିତେ |

-

ବାସ୍ତବ ଦୁନିଆର ଅପବ୍ୟବହାରରେ ସ୍ଥିରତା |

ଉଚ୍ଚ ପଙ୍କଚର ପ୍ରତିରୋଧ, ସ୍ଥିର ସିଲ୍, ଏବଂ ତାପମାତ୍ରା ସୁଇଙ୍ଗ୍ ମଧ୍ୟରେ କ୍ରମାଗତ କୁଶନ ରିଟର୍ନ ଏବଂ ରିପ୍ଲେସମେଣ୍ଟ ହ୍ରାସ କରେ - 3PL ଏବଂ ରପ୍ତାନି ଗାଡ଼ି ପାଇଁ ଚାବି |

-

ଅଡିଟ୍-ପ୍ରସ୍ତୁତ, ନିୟମ-ସଚେତନ |

EPR / PPWR / SB54 ଧରିବା ସହିତ, କ୍ରେତାମାନେ ପୁନ y ବ୍ୟବହାର ଯୋଗ୍ୟ ଡିଜାଇନ୍, PCR ସୁସଙ୍ଗତତା ଏବଂ ସଫା ଲେବେଲିଂ ଆବଶ୍ୟକ କରନ୍ତି | ଚାଲୁଥିବା ଯନ୍ତ୍ରପାତି ବାଛିବା | ମନୋ-ସାମଗ୍ରୀ PE କିମ୍ବା PP | ଭବିଷ୍ୟତର ଅଦ୍ୟତନ ପାଇଁ ନମନୀୟ ରହିବାବେଳେ PCR ଚଳଚ୍ଚିତ୍ରଗୁଡିକ ସାମ୍ପ୍ରତିକ ନିୟମ ସହିତ ସମାନ ହେବାରେ ସାହାଯ୍ୟ କରେ | (EU PPWR ଫେବୃଆରୀ 2025 ରେ 18 ମାସର ରନୱେ ପରେ ଆବେଦନ ପର୍ଯ୍ୟାୟ ସହିତ ବଳବତ୍ତର ହେଲା; SB54 କାଲିଫର୍ଣ୍ଣିଆରେ ପ୍ୟାକେଜିଂ ପାଇଁ EPR କାର୍ଯ୍ୟକ୍ଷମ କରେ |)

-

ଏଣ୍ଟରପ୍ରାଇଜ୍ ମୂଲ୍ୟ ବୃଦ୍ଧି କରେ (ତୁମର “ଘର ମୂଲ୍ୟ” ସମାନ)

ଦୃ rob, ମଡ୍ୟୁଲାର୍ ଲାଇନରେ କେପେକ୍ସ ବ .େ | ଉଦ୍ଭିଦ କ୍ଷମତା | (OEE, FPY) ଏବଂ ପୁନ ale ବିକ୍ରୟ ମୂଲ୍ୟ | ଡକ୍ୟୁମେଣ୍ଟ୍ ହୋଇଥିବା ଅନୁପାଳନ ଏବଂ ବ valid ଧ ହୋଇଥିବା ସିଲ୍ ଗୁଣ ମଧ୍ୟ ପ୍ରତ୍ୟାବର୍ତ୍ତନ ବିପଦକୁ ହ୍ରାସ କରେ - ବ୍ରାଣ୍ଡ ଇକ୍ୱିଟି ଏବଂ ମୂଲ୍ୟ ନିର୍ଧାରଣକୁ ସିଧାସଳଖ ପ୍ରଭାବିତ କରେ |

-

ମାପନୀୟ ସ୍ୱୟଂଚାଳିତ + ଉନ୍ନତ ଏକକ ଅର୍ଥନୀତି |

ଚଳଚ୍ଚିତ୍ରକୁ ଡାଉନଗାଉଙ୍ଗ୍ କରିବା, PCR ମିଶ୍ରଣ ଚଳାଇବା, ଏବଂ ସ୍କ୍ରାପ୍ କାଟିବା COGS କୁ ସ୍ଥିର କରିଥାଏ | 2027 ସୁଦ୍ଧା ଯନ୍ତ୍ରପାତି ପଠାଇବା ଏବଂ ବହୁ ବର୍ଷର ଅଭିବୃଦ୍ଧିରେ PMMI ରିପୋର୍ଟ କରିଛି |

ପ୍ଲାଷ୍ଟିକ୍ ଏୟାର ତକିଆ ତିଆରି ମେସିନ୍ |

ପାର୍ଶ୍ୱରେ: କେଉଁ କୁଶନ ଫର୍ମାଟ୍ ଆପଣଙ୍କ ପାଇଁ ଫିଟ୍?

| କେସ୍ / ସମ୍ପତ୍ତି ବ୍ୟବହାର କରନ୍ତୁ | | ଏୟାର ତକିଆ | | ବାୟୁ ସ୍ତମ୍ଭ | ଏୟାର ବବଲ୍ | |

| ପାଇଁ ସର୍ବୋତ୍ତମ | କାର୍ଟନ୍ ଭରିବା | | ଦୁର୍ବଳ, ବିସ୍ତାରିତ, ଉଚ୍ଚ ମୂଲ୍ୟର ଆଇଟମ୍ | | ବିଭିନ୍ନ ଆକୃତି ପାଇଁ ଚାରିଆଡେ ସୁରକ୍ଷା | |

| କୁଶନ ସମାନତା | | ଭଲ | ଉତ୍କୃଷ୍ଟ (ମଲ୍ଟି-ଚାମ୍ବର) | ବହୁତ ଭଲ |

| ସାମଗ୍ରୀ ବ୍ୟବହାର | | ପ୍ୟାକ୍ ପିଛା ସର୍ବନିମ୍ନ | | ମଧ୍ୟମ | ମଧ୍ୟମ-ଉଚ୍ଚ (କିନ୍ତୁ ଉତ୍ତମ ଧାରର ସୁରକ୍ଷା) |

| ଗତି | ବହୁତ ଉଚ୍ଚ | | ଉଚ୍ଚ | ଉଚ୍ଚ |

| କ୍ଷତି ହ୍ରାସ | 20-40% ସାଧାରଣ ବନାମ କାଗଜ ଶୂନ୍ୟ ଭରଣ (ପ୍ରୟୋଗ-ନିର୍ଦ୍ଦିଷ୍ଟ) | ଗ୍ଲାସ / ଇଲେକ୍ଟ୍ରୋନିକ୍ସ ପାଇଁ ସର୍ବୋଚ୍ଚ | | ପ୍ରସାଧନ ସାମଗ୍ରୀ, ପୁସ୍ତକ, ଉପହାର ପାଇଁ ଶକ୍ତିଶାଳୀ | |

| ଚଳଚ୍ଚିତ୍ର ବିକଳ୍ପଗୁଡ଼ିକ | PE, PCR ମିଶ୍ରିତ | | PE / PA ସହ-ପୂର୍ବ; ମୁଦ୍ରଣଯୋଗ୍ୟ ସ୍ଲିଭସ୍ | | PE ବବୁଲ୍; ଆଣ୍ଟି-ସ୍ଲିପ୍ ଟେକ୍ସଚର୍ | |

| ରେଖା ଏକୀକରଣ | | ସରଳ | ମାଣ୍ଡ୍ରେଲ୍ ସେଟ୍ ସହିତ ସରଳ | | ସରଳ; ରାପ୍ ଷ୍ଟେସନ୍ ସହିତ ଯୋଡି | |

| ଇନୋପ୍ୟାକ୍ ଲିଙ୍କ୍ | | ଏୟାର ତକିଆ | | ବାୟୁ ସ୍ତମ୍ଭ | ଏୟାର ବବଲ୍ | |

ଆମାଜନ ପ୍ରଭାବ: ଆମାଜନ ପ୍ଲାଷ୍ଟିକ୍ ଏୟାର ତକିଆରୁ ଅନେକ କ୍ଷେତ୍ରରେ କାଗଜ ଭରିବା ଆଡକୁ ଦୂରେଇ ଯାଇଛି, କାଗଜ କାମ କରିପାରିବ ବୋଲି ପ୍ରମାଣ କରୁଛି - କିନ୍ତୁ ଯେଉଁଠାରେ ବାୟୁ ପ୍ରଣାଳୀ ଜରୁରୀ ଅଟେ | ପ୍ରଭାବ ଶକ୍ତି ଏବଂ ଖୁଣ୍ଟ ବିପଦ ଅଧିକ, କିମ୍ବା ଯେଉଁଠାରେ ଟୋଟ୍ ଏବଂ କନଭେୟର ଆବଶ୍ୟକ କରନ୍ତି | ଫର୍ମ-ସ୍ଥିର କୁଶନ |.

ସାମଗ୍ରୀ ଏବଂ ନିର୍ମାଣ: ଇନୋପ୍ୟାକ୍ କ’ଣ ବାଛିଥାଏ (ଏବଂ ଏହା କାହିଁକି ଭଲ)

ଚଳଚ୍ଚିତ୍ର ଏବଂ ଉପଭୋକ୍ତା (ଅନୁପାଳନ ଏବଂ କାର୍ଯ୍ୟଦକ୍ଷତା ପାଇଁ ପରିକଳ୍ପିତ)

-

ମୋନୋ-ସାମଗ୍ରୀ PE / PP ଚଳଚ୍ଚିତ୍ର | ପୁନ yc ବ୍ୟବହାର ଯୋଗ୍ୟତା ଷ୍ଟ୍ରିମ୍ ଏବଂ ଲେବଲ୍ ସ୍ୱଚ୍ଛତାକୁ ସମର୍ଥନ କରିବାକୁ |

-

PCR- ପ୍ରସ୍ତୁତ | ଟ୍ୟୁନ୍ ହୋଇଥିବା ସିଲ୍ ୱିଣ୍ଡୋ ସହିତ ଚଳଚ୍ଚିତ୍ର ପରିଚାଳନା (10–50% PCR ଯେଉଁଠାରେ ଆପଣଙ୍କର ବ୍ରାଣ୍ଡ / ସ୍ପେକ୍ ଅନୁମତି ଦିଏ) |

-

ଟାଇଟ୍ ଗେଜ୍ ନିୟନ୍ତ୍ରଣ | ସ୍ୱୟଂଚାଳିତ ନିପ / ତାପମାତ୍ରା ପରିଚାଳନା ମାଧ୍ୟମରେ ତେଣୁ ଡାଉନଗ୍ୟାଗ୍ ସିଲ୍ କିମ୍ବା ବିସ୍ଫୋରଣ ଶକ୍ତିକୁ ସାମ୍ନା କରେ ନାହିଁ |

-

ମାର୍କେଟ-ଆଲାଇନ୍ ଲେବେଲିଂ | ପୁନ yc ବ୍ୟବହାର ପାଇଁ (ଅଞ୍ଚଳ-ନିର୍ଦ୍ଦିଷ୍ଟ), PPWR, ୟୁକେ ପ୍ଲାଷ୍ଟିକ୍ ପ୍ୟାକେଜିଂ ଟ୍ୟାକ୍ସ ରେକର୍ଡ ଏବଂ ଉତ୍ତର ଆମେରିକାର ନିର୍ଦ୍ଦେଶାବଳୀ ସହିତ ସମାନ୍ତରାଳ |

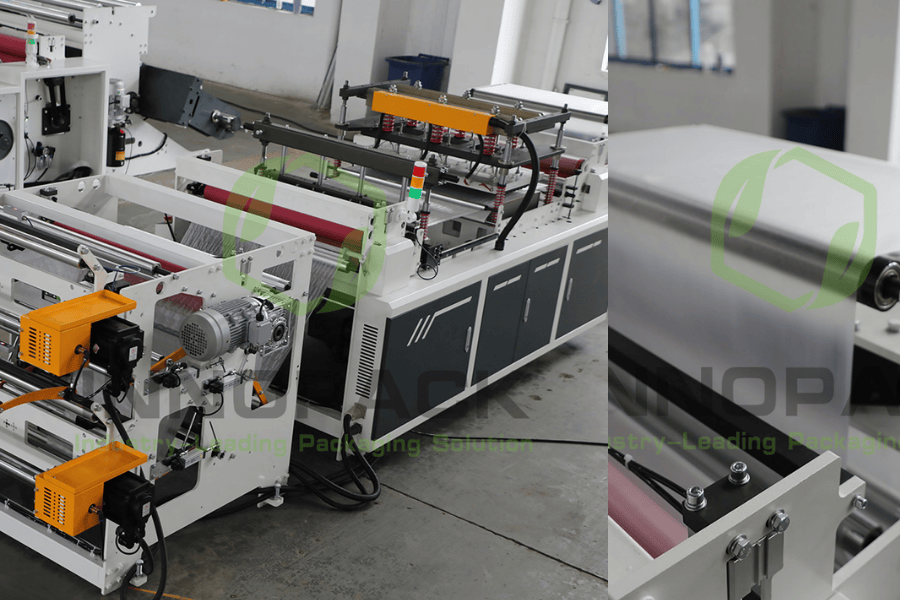

ମେସିନ୍ ଗଠନ ଏବଂ ମୂଳ ଉପାଦାନଗୁଡ଼ିକ |

-

କଠିନ ୱେଲଡେଡ୍ ଫ୍ରେମ୍ | ପାଉଡର-ଆବୃତ ଷ୍ଟିଲରେ କିମ୍ବା ୱାଶଡାଉନ୍ ଜୋନ୍ ପାଇଁ ଷ୍ଟେନଲେସ୍ |

-

ସର୍ଭୋ-ଚାଳିତ ଅନ୍ୱିଣ୍ଡ୍ ଏବଂ ଫିଡ୍ | ବେଗରେ ୱେବ୍ ଟେନସନ୍ ସଠିକତା ପାଇଁ |

-

ବନ୍ଦ-ଲୁପ୍ ଉତ୍ତାପକାରୀ ଏବଂ ସିଲ୍ ଜହ୍ନ | PCR ମିଶ୍ରଣରେ ସିଲ୍ ରକ୍ଷା କରିବା ପାଇଁ ରେସିପି ଲକିଂ ସହିତ |

-

ଶିଳ୍ପ PLC + HMI | (ରେସିପି ମେମୋରୀ, OEE ସ୍କ୍ରିନ୍, ରିମୋଟ୍ ଡାଇଗ୍ନୋଷ୍ଟିକ୍) |

-

ଦର୍ଶନ / ଓଜନ / ଚାପ ଯାଞ୍ଚ | ସିଲ୍ ଅଖଣ୍ଡତା ଏବଂ ପ୍ରିଣ୍ଟ୍ / ଲଟ୍ କୋଡ୍ ପାଇଁ - ଅଡିଟ୍ ପାସ୍ କରିବା ପାଇଁ ଗୁରୁତ୍ୱପୂର୍ଣ୍ଣ |

“ଖଣିଜ ପଦାର୍ଥ” ଅପେକ୍ଷା ଏହା କାହିଁକି ଭଲ:

PCR ଚଳଚ୍ଚିତ୍ର ଭେରିଏବିଲିଟି ଏବଂ ଡ୍ରିଫ୍ଟ ସହିତ କମୋଡିଟି ୟୁନିଟ୍ ସଂଘର୍ଷ କରେ | ଇନୋପ୍ୟାକ୍ ର ତାପମାତ୍ରା / ଚାପ ନିୟନ୍ତ୍ରଣ ଏବଂ ନିପ୍ ଡିଜାଇନ୍ ସିଲ୍ ୱିଣ୍ଡୋକୁ ସ୍ଥିର କରିଥାଏ, ଗତି ବଜାୟ ରଖେ | ବିନା ସ୍କ୍ରାପ୍ କିମ୍ବା ମାଇକ୍ରୋ ଲିକର୍ ବ raising ାଇବା |

ପ୍ରୋସେସ୍ ଇଞ୍ଜିନିୟରିଂ: କିପରି ଇନୋପ୍ୟାକ୍ ମେସିନ୍ଗୁଡ଼ିକ ସ୍ଥାୟୀ ସୁରକ୍ଷା ସୃଷ୍ଟି କରେ |

ଏୟାର ପିଲୋ (ଶୂନ୍ୟ ପୂରଣ, omni-SKU)

-

ଚଳଚ୍ଚିତ୍ର ଅନ୍ୱିଣ୍ଡ୍ → ଫର୍ମ → ସିଲ୍ → ପର୍ଫୋରେଟ୍ → ଇନଫ୍ଲେଟ୍ | ଗୋଟିଏ ପାସ୍ ରେ |

-

ଅଟୋ-ବିଭାଜନ | ରେଖା ଚାଲୁ ରଖେ; 60 ସେକେଣ୍ଡ ତଳେ ରିଲ୍ ପରିବର୍ତ୍ତନ |

-

ପ୍ରତି ତକିଆ ବିସ୍ଫୋରଣ ପରୀକ୍ଷଣ | ଏବଂ ଇଚ୍ଛାଧୀନ ଇନ-ଲାଇନ୍ ଚାପ ଯାଞ୍ଚ କ୍ଷତି ହ୍ରାସ କରେ |

ନବୀକରଣ ପଥ: ଯୋଡନ୍ତୁ | ମଡ୍ୟୁଲ୍ ପ୍ରିଣ୍ଟ୍ କରନ୍ତୁ | ଲୋଗୋ / ପାଚନ ଚିହ୍ନ ପାଇଁ; ଟ୍ୟୁନ୍ କରନ୍ତୁ | ବବୁଲ୍ ଜ୍ୟାମିତି | SKU ଦ୍ୱାରା

ବାୟୁ ସ୍ତମ୍ଭ (ପ୍ରିମିୟମ୍ ସୁରକ୍ଷା)

-

ସ୍ଲିଭ୍ ଗଠନ | ଆପଣଙ୍କ ଉତ୍ପାଦ ପ୍ରୋଫାଇଲ୍ ଚାରିପାଖରେ ମଲ୍ଟି-ଚାମ୍ବର ଏୟାର ସ୍ତମ୍ଭ ସହିତ |

-

ମଲ୍ଟି ଚାମ୍ବର ଅନାବଶ୍ୟକତା |: ଯଦି ଗୋଟିଏ କକ୍ଷ ସଙ୍କଟାପନ୍ନ ହୁଏ, ଅନ୍ୟମାନେ ବ ated ିଯାଏ |

-

ମାଣ୍ଡ୍ରେଲ୍ / ରେସିପି ଅଦଳବଦଳ | ଦ୍ରୁତ ପରିବର୍ତ୍ତନ ପାଇଁ (ଗ୍ଲାସୱେୟାର, ଇଲେକ୍ଟ୍ରୋନିକ୍ସ, ଲ୍ୟାବ ଗିଅର) |

ଫୋମ୍ / ଖାଲି ଭରିବା ଅପେକ୍ଷା ଭଲ: ଲୋୟର ମେସ୍, କ୍ରମାଗତ ଶକ୍ତି ଅବଶୋଷଣ, ବୃତ୍ତିଗତ ଅନ୍ବକ୍ସିଂ |

ଏୟାର ବବୁଲ୍ (ଗୁଡ଼ାଇ ଏବଂ ଧାର ସୁରକ୍ଷା)

-

ଚଳଚ୍ଚିତ୍ର ନିପ୍ + ଏମ୍ବୋସ୍ + ସିଲ୍ ପ୍ୟାଟର୍ | ସହିତ ବୁବୁଲ୍ସ ସୃଷ୍ଟି କରେ | ପୂର୍ବାନୁମାନଯୋଗ୍ୟ କ୍ରସ୍ ବକ୍ରଗୁଡିକ |.

-

ଆଣ୍ଟି-ସ୍ଲିପ୍ ଟେକ୍ସଚର୍ | ବଣ୍ଡଲ୍ଗୁଡ଼ିକୁ ଟାଣ ରଖ; ବ al କଳ୍ପିକ ସହଜ ଲୁହ ସ୍କୋରିଂ |.

-

ଷ୍ଟେସନ୍ ଗୁଡ଼ିକ | କେସ୍ ପ୍ୟାକର୍ ଏବଂ ଲେବେଲର୍ ସହିତ ଏକୀକୃତ କରନ୍ତୁ - କ man ଣସି ମାନୁଆଲ୍ ଟ୍ୟାପିଂ ନାହିଁ |

ସ୍ଥିରତା କାହିଁକି ବାସ୍ତବ: ବବୁଲ୍ ଜ୍ୟାମିତି + ସ୍ଥିର ସିଲ୍ ଘନତା → ପୁନରାବୃତ୍ତି ଡ୍ରପ୍ ଫଳାଫଳ, କମ୍ କୋଣ ଫାଟ |

ମଡେଲଗୁଡିକ ଏକ୍ସପ୍ଲୋର୍ କରନ୍ତୁ:

ବିଶେଷଜ୍ଞ ଅନ୍ତର୍ଦୃଷ୍ଟି ଏବଂ ଶିଳ୍ପ ପ୍ରସଙ୍ଗ |

-

ନିୟାମକ ରନ୍ୱେ: The EU PPWR | ଫେବୃଆରୀ 2025 ରେ ଲାଗୁ ହେଲା, 18 ମାସର ଆବେଦନ ସମୟସୀମା ଏବଂ 2040 ପର୍ଯ୍ୟନ୍ତ ଷ୍ଟେଜ୍ ପଦକ୍ଷେପ ସହିତ, ପୁନ yc ବ୍ୟବହାର ଏବଂ ସାମଗ୍ରୀ ହ୍ରାସକୁ ପ୍ରବର୍ତ୍ତାଇଲା |

-

ଉତ୍ତର ଆମେରିକା: କାଲିଫର୍ନିଆ SB54 | ପ୍ୟାକେଜିଂ EPR କୁ ଆନୁଷ୍ଠାନିକ କରେ; ଉତ୍ପାଦକମାନେ ପୁନ yc ବ୍ୟବହାର ପାଇଁ ପାଣ୍ଠି ଦେବା ଆବଶ୍ୟକ ଏବଂ ରାଜ୍ୟ ନିୟମ ଅନୁଯାୟୀ ସାମଗ୍ରୀଗୁଡିକ ପୁନ y ବ୍ୟବହାର ଯୋଗ୍ୟ / କମ୍ପୋଷ୍ଟେବଲ୍ ବୋଲି ନିଶ୍ଚିତ କରନ୍ତୁ |

-

ବିଶ୍ୱସ୍ତରୀୟ ଦୃଷ୍ଟିକୋଣ: UNEP ଅଣ୍ଡରସ୍କୋରସ୍> ବାର୍ଷିକ 400 ମି ଟନ୍ ପ୍ଲାଷ୍ଟିକ୍ ଉତ୍ପାଦିତ, ବୃତ୍ତାକାର ଆଭିମୁଖ୍ୟ ଏବଂ କର୍ପୋରେଟ୍ କାର୍ଯ୍ୟ |

-

ବଜାର ଚାହିଦା: PMMI ପ୍ୟାକେଜିଂ ଯନ୍ତ୍ରପାତି ପାଇଁ ଶିଳ୍ପ ଅଭିବୃଦ୍ଧି ଏବଂ ସ୍ଥାୟୀ ପଠାଣ ସ୍ତରଗୁଡିକ ଟିପ୍ପଣୀ କରେ; ବିନିଯୋଗ ସ୍ୱୟଂଚାଳିତ, ଯାଞ୍ଚ ଏବଂ ନମନୀୟତା ପ୍ରତି ପକ୍ଷପାତିତ |

-

ଫର୍ମାଟ୍ ଅଭିବୃଦ୍ଧି: ପାଉଚ୍ ଏବଂ ନମନୀୟ ପ୍ୟାକେଜିଂ ସର୍ବଭାରତୀୟ ସ୍ତରରେ ବିସ୍ତାର କରିବାରେ ଲାଗିଛି | ସ୍ମିଥର୍ସ | 2029 ପର୍ଯ୍ୟନ୍ତ ପୂର୍ବାନୁମାନ - ମୋନୋ-ମ୍ୟାଟେରିଆଲ୍ ଚଳଚ୍ଚିତ୍ର ରଣନୀତି ପାଇଁ ପ୍ରାସଙ୍ଗିକ |

ବିଶେଷଜ୍ଞ ନିଅନ୍ତୁ (ଲଜିଷ୍ଟିକ୍): “ରିସାଇକ୍ଲେବିଲିଟି ପାଇଁ ଡିଜାଇନ୍ କରିବା ମନ୍ଥର ଗତିର ଅର୍ଥ ନୁହେଁ | ଏହାର ଅର୍ଥ ହେଉଛି ମେସିନ୍ କିଣିବା | PCR ଚଳଚ୍ଚିତ୍ର ସହିତ ଗତି ଧର | ଏବଂ ଲାଇନ୍ରେ ସିଲ୍ ବ valid ଧ କରନ୍ତୁ | ” - ଲଜିଷ୍ଟିକ୍ ଇଞ୍ଜିନିୟରିଂ ନିର୍ଦ୍ଦେଶକ, EU 3PL |

ହୋଲସେଲ ପ୍ଲାଷ୍ଟିକ୍ ଏୟାର ତକିଆ ତିଆରି ମେସିନ୍ |

ବ Scientific ଜ୍ଞାନିକ ଏବଂ ବଜାର ତଥ୍ୟ |

-

EPA: ଧାରଣକାରୀ ଏବଂ ପ୍ୟାକେଜିଂ ଗଠିତ ~82.2 ନିୟୁତ ଟନ୍ | 2018 ରେ MSW ପି generation ଼ିର (ସମୁଦାୟର ≈28.1%) - ସର୍କୁଲାର ଏବଂ ହ୍ରାସ ପାଇଁ ପ୍ୟାକେଜିଂକୁ ମୁଖ୍ୟ ଲକ୍ଷ୍ୟ କରି |

-

PMMI: ଯୁକ୍ତରାଷ୍ଟ୍ର ପ୍ୟାକେଜିଂ ଯନ୍ତ୍ରପାତି ପଠାଣ ପହଞ୍ଚିଲା | 2023 ରେ $ 10.9B |, 5.8% YoY ପର୍ଯ୍ୟନ୍ତ; ଅଭିବୃଦ୍ଧି 2027 ପର୍ଯ୍ୟନ୍ତ ଜାରି ରହିବ ବୋଲି ଆଶା କରାଯାଉଛି |

-

UNEP: ସିଷ୍ଟମ୍ ପରିବର୍ତ୍ତନ ପାଇଁ ଆହ୍ —ାନ-ପୁନ ori ପରିବର୍ତ୍ତନ / ବିବିଧକରଣ, ପୁନ use ବ୍ୟବହାର, ପୁନ y ବ୍ୟବହାର |- ଉତ୍ପାଦ ଏବଂ ସିଷ୍ଟମ ପୁନ es ନିର୍ମାଣ ମାଧ୍ୟମରେ ପ୍ଲାଷ୍ଟିକ ପ୍ରଦୂଷଣକୁ ରୋକିବା |

-

ଆମାଜନ FFP |: ଖୁଚୁରା ବ୍ୟବସାୟୀ / ପ୍ଲାଟଫର୍ମଗୁଡ଼ିକ ଅଧିକ ଆବଶ୍ୟକ କରନ୍ତି | curbside-recyclable ପ୍ୟାକେଜିଂ | ଏବଂ ଦ୍ରୁତ ଖୋଲାତା; ଅଡିଟ୍ ପାସ୍ କରିବା ପାଇଁ ପ୍ରିଣ୍ଟ୍, ସାମଗ୍ରୀ, ଏବଂ ଜ୍ୟାମିତିକୁ ପ୍ୟାକ୍ କରନ୍ତୁ |

-

ୟୁକେ ପ୍ଲାଷ୍ଟିକ୍ ପ୍ୟାକେଜିଂ ଟ୍ୟାକ୍ସ |: ପଞ୍ଜୀକରଣ ସୀମା ଏବଂ ପୁନ yc ବ୍ୟବହାର-ବିଷୟବସ୍ତୁ ମାନଦଣ୍ଡ PCR ଗ୍ରହଣ ଏବଂ ଚଳଚ୍ଚିତ୍ର ଚରିତ୍ର ପାଇଁ ଡାଟା ଟ୍ରାକିଂ ଡ୍ରାଇଭ୍ |

ବ୍ୟବହାରିକ କାର୍ଯ୍ୟକାରିତା |

-

ପ୍ରିମିୟମ୍ ଗ୍ଲାସୱେର୍ ରପ୍ତାନିକାରୀ (EU → NA)

କୁ ସୁଇଚ୍ ହୋଇଛି | ବାୟୁ ସ୍ତମ୍ଭ ଷ୍ଟେମୱେର୍ ପାଇଁ; କ୍ଷତି ହ୍ରାସ ପାଇଛି | 43% ଏବଂ ଗ୍ରାହକ NPS ବୃଦ୍ଧି ପାଇଲା | ବ୍ୟାଚ୍ ସ୍ତରୀୟ QR ଉନ୍ନତ ଟ୍ରେସେବିଲିଟି ପ୍ରିଣ୍ଟ୍ କରେ |

ସାଧନ: ଏୟାର ସ୍ତମ୍ଭ ମାଣ୍ଡ୍ରେଲ୍ସ, ରେସିପି ଲକ୍, ବିସ୍ଫୋରଣ ପରୀକ୍ଷଣ ନମୁନା |

-

ହୋମ୍ ଫିଟନେସ୍ ବ୍ରାଣ୍ଡ (US DTC)

ଫୋମ୍ + ଟେପ୍ ସହିତ ବଦଳାଯାଇଛି | ବାୟୁ ବବୁଲ୍ ରାପ୍ |; ଉଠାଇଲେ 12% UGC ପାଇଁ ଦ୍ରୁତ ପ୍ୟାକ୍ ସମୟ ଏବଂ କ୍ଲିନର୍ ଅନ୍ବକ୍ସିଂ ବିଷୟବସ୍ତୁ |

ସାଧନ: ଆଣ୍ଟି-ସ୍ଲିପ୍ ଟେକ୍ସଚର୍ ରୋଲ୍, SKU ଓଜନ ଦ୍ୱାରା ଅଟୋ-କଟ୍ ଲମ୍ବ |

-

ପୁସ୍ତକ ଏବଂ ମିଡିଆ 3PL (APAC)

ଗ୍ରହଣ କରାଯାଇଛି ବାୟୁ ତକିଆ | ଶୂନ୍ୟ ଭରଣ ପାଇଁ; ହାସଲ ହୋଇଛି | 7% DIM ସଞ୍ଚୟ ଏବଂ କମ୍ କୋଣାର୍କ କ୍ରସ୍ ଦାବି |

ସାଧନ: ଅଟୋ-ସ୍ପ୍ଲିକର୍, ଇନ୍-ଲାଇନ୍ ପ୍ରିଣ୍ଟ୍ “ରିସାଇକ୍ଲେବଲ୍ - ଲୋକାଲ୍ ପ୍ରୋଗ୍ରାମ୍ ଯାଞ୍ଚ କର |”

ଆମ ବିଷୟରେ: ଇନୋପ୍ୟାକ୍ ଯନ୍ତ୍ରପାତି | ଯୋଗାଣ ଏକତ୍ରିତ | ପ୍ଲାଷ୍ଟିକ୍ ପ୍ୟାକେଜିଂ ଯନ୍ତ୍ର |- ଠାରୁ ବାୟୁ ତକିଆ | କୁ ବାୟୁ ସ୍ତମ୍ଭ ଏବଂ ବାୟୁ ବବୁଲ୍ | ସିଷ୍ଟମ୍ - ଗ୍ଲୋବାଲ୍ ସର୍ଭିସ୍ ଏବଂ ସ୍ପେୟାର୍ ସହିତ | ଆମର ପୋର୍ଟଫୋଲିଓ ଦେଖନ୍ତୁ: innopackmachinery.com/plastic-packaging-machinery.

ବ୍ୟବହାରକାରୀ ମତାମତ (ମନୋନୀତ)

-

SKU ପ୍ରତି ରେସିପି ସଞ୍ଚୟ ସହିତ ଅଧ ଘଣ୍ଟାରୁ ଦଶ ମିନିଟ ପର୍ଯ୍ୟନ୍ତ ପରିବର୍ତ୍ତନ ହୋଇଗଲା | ” - ଓପ୍ସ ଲିଡ୍, ଡି

-

ଆମେ ପୂର୍ଣ୍ଣ ବେଗରେ 30% PCR ଚଳଚ୍ଚିତ୍ର ଚଳାଉଛୁ; ସିଲ୍ ଧରିଛି, ଅଭିଯୋଗ ହ୍ରାସ ପାଇଛି। ” - ପ୍ୟାକେଜିଂ ମ୍ୟାନେଜର୍, CA

-

ଅଡିଟ୍ ବର୍ତ୍ତମାନ ଅଧିକ ସୁଗମ - ଲେବଲ୍ ଏବଂ ଡାଟା ଲଗ୍ ଟ୍ୟାକ୍ସ ଏବଂ ଇପିଆର ଆବଶ୍ୟକତା ସହିତ ମେଳ ଖାଉଛି। ” - କମ୍ପ୍ଲେନ୍ସ ହେଡ୍, ବ୍ରିଟେନ |

କ୍ରେତାଙ୍କ ଯାଞ୍ଚ ତାଲିକା |

ପ୍ରଦର୍ଶନ

-

ଟାର୍ଗେଟ୍ ସ୍ପିଡ୍ (ପ୍ୟାକ୍ / ମିନିଟ୍), ଶିଖର ଘଣ୍ଟା ଭଲ୍ୟୁମ୍, SKU ବିସ୍ତାର |

-

ସିଲ୍ ପ୍ରକାର (ଫିନ / ଲାପ୍), MAP ଆବଶ୍ୟକ?

-

PCR% ରେଞ୍ଜ, ଚଳଚ୍ଚିତ୍ର ଘନତା ୱିଣ୍ଡୋ |

ସ୍ୱୟଂଚାଳିତ ଏବଂ ତଥ୍ୟ |

-

ରେସିପି ଲକ୍ ସହିତ PLC / HMI, OEE ଡ୍ୟାସବୋର୍ଡ |, OPC UA / MQTT |

-

ଅଟୋ-ସ୍ପ୍ଲାଇସିଙ୍ଗ୍, ଅଟୋ ୱେବ୍ ଗାଇଡ୍, ଭିଜନ / ଓଜନ ଯାଞ୍ଚ |

ଅନୁକରଣ

-

ପୁନ yc ବ୍ୟବହାର ଯୋଗ୍ୟତା ଦାବିଗୁଡିକ ଅଞ୍ଚଳ ସହିତ ସମାନ ହୋଇଛି; ଲେବଲ୍ ମଡ୍ୟୁଲ୍ |

-

ପାଇଁ ରେକର୍ଡଗୁଡିକ | UK PPT, EU PPWR |, US SB54 ରିପୋର୍ଟ କରିବା

ସେବା

-

MTBF / MTTR ଟାର୍ଗେଟ୍, 24/7 ରିମୋଟ୍ ଡାଇଗ୍ନୋଷ୍ଟିକ୍, ସ୍ପେୟାର୍ କିଟ୍ |

-

FAT / SAT ଯୋଜନା, ତାଲିମ, SOP / PM ଡକ୍ୟୁମେଣ୍ଟ୍ |

ଏକ୍ସପ୍ରେସ ବିତରଣ ପାଇଁ ପ୍ଲାଷ୍ଟିକ୍ ଏୟାର ପିଲୋ |

FAQ

ପ୍ଲାଷ୍ଟିକ୍ ପ୍ୟାକେଜିଂ ଯନ୍ତ୍ର ପାଇଁ କ’ଣ ବ୍ୟବହୃତ ହୁଏ?

ଏହା ନମନୀୟ ଚଳଚ୍ଚିତ୍ର ଏବଂ ବାୟୁ ଭିତ୍ତିକ କୁଶନ (ତକିଆ / ସ୍ତମ୍ଭ / ବୁବୁଲ୍ସ) ବ୍ୟବହାର କରି ଉତ୍ପାଦ ଗଠନ କରେ, ପୂରଣ କରେ, ସିଲ୍ କରେ ଏବଂ ସୁରକ୍ଷା କରେ | ଇ-ବାଣିଜ୍ୟ, ଇଲେକ୍ଟ୍ରୋନିକ୍ସ, ପ୍ରସାଧନ ସାମଗ୍ରୀ, ପୁସ୍ତକ, ଏବଂ ଖର୍ଚ୍ଚ ପାଇଁ ଆଦର୍ଶ |

ନମନୀୟ ପ୍ଲାଷ୍ଟିକ୍ ନୂତନ ନିୟମ ଅନୁଯାୟୀ ଏପର୍ଯ୍ୟନ୍ତ ଅନୁମତିପ୍ରାପ୍ତ କି?

ହଁ - ଯେତେବେଳେ ଡିଜାଇନ୍ ହୋଇଛି | ପୁନ yc ବ୍ୟବହାର ଯୋଗ୍ୟତା |, PCR ବିଷୟବସ୍ତୁ ପାଇଁ ଟ୍ରାକ୍ ହୋଇଛି, ଏବଂ ସଠିକ୍ ଭାବରେ ଲେବଲ୍ ହୋଇଛି | PPWR / SB54 ପୁସ୍ ଅନୁପାଳନ, ସମସ୍ତ ପ୍ଲାଷ୍ଟିକ ଉପରେ କମ୍ବଳ ନିଷେଧ ନୁହେଁ |

ଗତି ହରାଇ ମୁଁ PCR ଚଳଚ୍ଚିତ୍ର ଚଲାଇ ପାରିବି କି?

ଟ୍ୟୁନ୍ ହୋଇଥିବା ସିଲ୍ ୱିଣ୍ଡୋ ଏବଂ ନିପ୍ କଣ୍ଟ୍ରୋଲ୍ ସହିତ, ହଁ | FAT / SAT ସମୟରେ ତୁମର ସଠିକ୍ ମିଶ୍ରଣ ଉପରେ ବ Val ଧତା କର |

ବାୟୁ ତକିଆ ବନାମ ବାୟୁ ସ୍ତମ୍ଭ - ଯାହା ଭଲ ସୁରକ୍ଷା କରେ?

ଭଗ୍ନ, ବିସ୍ତାରିତ, କିମ୍ବା ଉଚ୍ଚ ମୂଲ୍ୟର ଆଇଟମ୍ ପାଇଁ, ବାୟୁ ସ୍ତମ୍ଭ ଜିତେ | ବେଗରେ ସାଧାରଣ ଶୂନ୍ୟତା ପୂରଣ ପାଇଁ, ବାୟୁ ତକିଆ | ସବୁଠାରୁ ଖର୍ଚ୍ଚଦାୟକ ଅଟେ |

ଏହି ଅପଗ୍ରେଡ୍ କିପରି “ମୂଲ୍ୟ ବୃଦ୍ଧି” କରେ?

ଉଚ୍ଚ OEE, କମ୍ ରିଟର୍ନ, ବ valid ଧ ଅନୁପାଳନ, ଏବଂ ଉନ୍ନତ ଅନ୍ବକ୍ସିଂ ମାର୍ଜିନ ଏବଂ ବ୍ରାଣ୍ଡ ଇକ୍ୱିଟି ବ raise ାଇଥାଏ - ଆପଣଙ୍କ ସୁବିଧାର ସମ୍ପତ୍ତି ମୂଲ୍ୟରେ ଉନ୍ନତି ଆଣେ |

ତୁମର ପରବର୍ତ୍ତୀ, ସର୍ବୋତ୍ତମ ପ୍ୟାକେଜିଂ ଡଲାର୍ |

କୁ ଅପଗ୍ରେଡ୍ କରିବା ପ୍ଲାଷ୍ଟିକ୍ ପ୍ୟାକେଜିଂ ଯନ୍ତ୍ର | ଏକ ରଣନୀତିକ ବ୍ୟାଟ୍ ଅଟେ | ସ୍ଥାୟୀତ୍ୱ, ଗତି, ଏବଂ ଅନୁପାଳନ |। ଆପଣ ଚଳାଉଛନ୍ତି କି ନାହିଁ | ବାୟୁ ତକିଆ | ଶୂନ୍ୟ ପୂରଣ ପାଇଁ, ବାୟୁ ସ୍ତମ୍ଭ ପ୍ରିମିୟମ୍ ଭଗ୍ନତା ପାଇଁ, କିମ୍ବା ବାୟୁ ବବୁଲ୍ | ରାପ୍ ଚାରିପାଖର ସୁରକ୍ଷା ପାଇଁ, ତୁମେ ଶୀଘ୍ର ପଠାଇବ, କମ୍ ଭାଙ୍ଗିବ, ଏବଂ ଅଡିଟ୍ ରେ ଉଚ୍ଚରେ ଠିଆ ହେବ | PPWR / SB54 ଏବଂ ଆମାଜନ FFP ପରି ପ୍ଲାଟଫର୍ମ ନିୟମ ଦୁନିଆରେ, ସ୍ମାର୍ଟ ଟଙ୍କା ହେଉଛି ସିଷ୍ଟମରେ | ଉତ୍ପାଦ ଏବଂ ବାଲାନ୍ସ ସିଟ୍ ସୁରକ୍ଷା କରନ୍ତୁ |- ଆଜି ଏବଂ 2030 ପର୍ଯ୍ୟନ୍ତ

ନିୟମ, ବଜାର ଗଣିତ, ଏବଂ ଅପରେସନ୍ ସାଇନ୍ସ ସମାନ ଉତ୍ତରରେ ଏକତ୍ରିତ ହେଉଛି: ପ୍ଲାଷ୍ଟିକ୍ ପ୍ୟାକେଜିଂ ମେସିନାରୀରେ ବିନିଯୋଗ କରନ୍ତୁ ଯାହା ମୋନୋ-ମ୍ୟାଟେରିଆଲ୍ ଚଳଚ୍ଚିତ୍ର ଚଳାଇପାରେ, PCR ଭେରିଏବିଲିଟି ସହ୍ୟ କରିପାରିବ ଏବଂ ସିଲ୍ ଗୁଣବତ୍ତା ଯାଞ୍ଚ କରିବ | ୟୁରୋପରେ, PPWR ଫେବୃଆରୀ 11, 2025 ରେ 18 ମାସ ପରେ ପ୍ରୟୋଗ ସହିତ ବଳବତ୍ତର ହେଲା - ଡିଜାଇନ୍ ଦ୍ rec ାରା ପୁନ yc ବ୍ୟବହାର ଯୋଗ୍ୟତା ଏବଂ ଉତ୍ପାଦକମାନଙ୍କୁ ବୃତ୍ତାକାର, ନିମ୍ନ ବର୍ଜ୍ୟବସ୍ତୁ ଫର୍ମାଟ ଆଡକୁ ଠେଲି | ଯୁକ୍ତରାଷ୍ଟ୍ରରେ, କାଲିଫର୍ନିଆ SB 54 ପ୍ୟାକେଜିଂ EPR କୁ ଆନୁଷ୍ଠାନିକ କରେ, ଉତ୍ପାଦକମାନଙ୍କୁ ପୁନ y ବ୍ୟବହାର ଯୋଗ୍ୟ / କମ୍ପୋଷ୍ଟେବଲ୍ ସୁନିଶ୍ଚିତ କରିବା ଏବଂ ଜୀବନର ଶେଷ ପ୍ରଣାଳୀକୁ ପାଣ୍ଠି ଦେବା ପାଇଁ ଆବଶ୍ୟକ କରେ | ଚୁକ୍ତିନାମା ଆବଶ୍ୟକତା ଅନୁଯାୟୀ ଲେବଲ୍ ଏବଂ ମୋନୋ-ମ୍ୟାଟେରିଆଲ୍ ଚଳଚ୍ଚିତ୍ର ସଫା କରନ୍ତୁ |

ଏହି ସମୟରେ, ଯନ୍ତ୍ରପାତି ବଜାର ଆଧୁନିକୀକରଣ କରୁଥିବା ଉଦ୍ଭିଦଗୁଡିକୁ ପୁରସ୍କୃତ କରେ: PMMI ର 2024 ଷ୍ଟେଟ୍ ଅଫ୍ ଇଣ୍ଡଷ୍ଟ୍ରି 2023 (+ 5.8% YoY) ପାଇଁ ଆମେରିକାର ପ୍ୟାକେଜିଂ ମେସିନାରୀ ପଠାଣରେ $ 10.9B ରିପୋର୍ଟ କରିଛି ଏବଂ 2027 ସୁଦ୍ଧା ଏକ ପୁନର୍ବାର ଟ୍ରାଜେକ୍ଟୋରୀ - ପ୍ରକୃତ ROI ସହିତ ସ୍ୱୟଂଚାଳିତତା ତ୍ୱରାନ୍ୱିତ ହେଉଛି, ଅଟକି ନାହିଁ |

ରଣନ ically ତିକ ଦୃଷ୍ଟିରୁ, ଏହା UNEP ର ପଥ ସହିତ 2040 ସୁଦ୍ଧା ପ୍ଲାଷ୍ଟିକ୍ ପ୍ରଦୂଷଣକୁ 80% ପର୍ଯ୍ୟନ୍ତ ପୁନ es ଡିଜାଇନ୍, ପୁନ use ବ୍ୟବହାର ଏବଂ ପ୍ରଭାବଶାଳୀ ପୁନ yc ବ୍ୟବହାର ମାଧ୍ୟମରେ ହ୍ରାସ କରିବାକୁ ଯଥା - ଉତ୍ତମ ସାମଗ୍ରୀ ଏବଂ ସ୍ମାର୍ଟ ମେସିନ୍ ଦ୍ୱାରା ସକ୍ଷମ ହୋଇଥିବା ସଠିକ୍ ଲିଭରଗୁଡିକ |

ନିମ୍ନ ରେଖା: ଉତ୍ପାଦ ଏବଂ ବାଲାନ୍ସ ଶୀଟ୍ କୁ ସୁରକ୍ଷା ଦେଉଥିବା ସିଷ୍ଟମଗୁଡିକ ବାଛନ୍ତୁ - ହାଇ ସ୍ପିଡ୍ ଲାଇନ୍ ଯାହା ପୁନ yc ବ୍ୟବହୃତ ବିଷୟବସ୍ତୁ ଉପରେ ସିଲ୍ ଅଖଣ୍ଡତା ଧାରଣ କରେ, ସ୍ୱୟଂଚାଳିତ ଭାବରେ ଅଡିଟ୍ ଡାଟା ଲଗ୍ କରେ ଏବଂ SKU ଗୁଡ଼ିକୁ ନିର୍ଦ୍ଦିଷ୍ଟ ଭାବରେ ଚାଲୁ ରଖେ | ତାହା ହେଉଛି ଅପଗ୍ରେଡ୍ ପଥ ଇନୋପ୍ୟାକ୍ ମେସିନାରୀ ଡିଜାଇନ୍ - ଶୂନ୍ୟ-ପୂର୍ଣ୍ଣ (ଏୟାର ତକିଆ), ଏୟାର ସ୍ତମ୍ଭ, ଏବଂ ଏୟାର ବବୁଲ୍ସ - ତେଣୁ ତୁମେ ଶୀଘ୍ର ପଠାଇବ, କମ୍ ଭାଙ୍ଗିବ ଏବଂ ପ୍ରଥମ ଚେଷ୍ଟାରେ ଅଡିଟ୍ ପାସ୍ କରିବ |