Ukugcwaliseka kwesikali Ngomshini Wokwenza Imeyili Ehlanganisiwe ovela ku-Innopack. Khiqiza izimvilophu ezinamabhrendi, ezigaywe kabusha noma ze-PCR-ifilimu efakwe ngesivinini, usike isisindo se-DIM kanye nomonakalo, futhi uphumelele ukucwaninga ngokuhlolwa kwe-inline seal kanye nokulandeleka kweleveli ye-batch ye-e-commerce kanye nama-3PLs.

Ingxoxo yokuvula :Umphathi we-Ops: "Izimbuyiselo seziphelile, ukuhlolwa kwamaphakheji kuqinile, futhi iziteshi zethu zamaphakethe azikwazi ukuqhubeka. Yini engalungisa konke okuthathu?"

Unjiniyela Wokupakisha: "Thuthukela Kumshini Wokwenza Imeyili Ehlanganisiwe. Okukhethwa kukho okusekelwe ephepheni, onqenqemeni lwe-curbside, ukuvala uphawu ngesivinini esikhulu, kanye nokulimala okuncane endleleni yokuhamba."

Umphathi we-Ops: "Ngibonise ukuthi ibuyisela kanjani-futhi yini eyenza ibe ngcono kunokusetha kwethu kwamanje."

Uyini Umshini Wokwenza Imeyili Ehlanganisiwe?

A Umshini Wokwenza Imeyili Ehlanganisiwe izenzela ngokuzenzakalelayo ukukhiqizwa kwezimvilophu ezinezimvilophu—okungaba ezigqize ngephepha (ezinemicu yephepha noma amabhamuza ephepha ahlelekile) noma ezenziwe ngepulasitiki (ezinamabhamuza omoya)—ezohwebo nge-elekthronikhi, i-3PL, izitolo, nezingxenye ezisele. Uma kuqhathaniswa nekhathoni le-ad-hoc + i-void-fill, ama-mailers ane-padded usayizi olungile iphakheji, usheshise ukugcwaliseka, futhi udale umuzwa ohlanzekile we-unboxing.

I-Core iwina ngo-2025:

-

Ukushintsha okusheshayo nokufaka uphawu okuzenzakalelayo = ukukhiqiza okuphezulu

-

Usayizi wesokudla, umthumeli weposi = Isisindo esincane se-DIM nomonakalo

-

Amafomethi wephepha angasebenza kabusha = ukuthobela okulula nesithombe somkhiqizo esiluhlaza

-

Ukulandelelwa kweqoqo = amadokhumenti alungele ukuhlolwa

Bona izixazululo ezihlobene: Imishini Yokufaka Amaphepha (yesisekelo sephepha kanye nezisekelo ezizenzakalelayo).

Izinto: Yini Engena Kumeyili Enamaphedi Angcono Kakhulu

Abahlinzeki Bemishini Yokwenza Imeyili Ehlanganisiwe

Iphepha Elinamathiselwe (kunconyiwe lapho ukugaywa kabusha kwe-curbside kubaluleke khona)

-

Ngaphandle: I-kraft eqinisekisiwe ye-FSC noma iphepha elimhlophe (80–180 gsm), liphrinteka ngohlobo/amalebula

-

Iphedi yangaphakathi: ungqimba lwe-fiber-padded, ikhekheba lezinyosi/iphepha elakhiwe, noma “amabhamuza” ephepha lokumuncwa ukushaqeka

-

I-Adhesive & seal: imichilo encibilikayo eshisayo noma ezwela ukucindezela; I-PFAS-mahhala ezinengilazi etholakalayo

-

Ukulebula: izithonjana zokugaywa kabusha neziqondiso zokulahla eziqondaniswe nezikimu zasendaweni

Kungani inamandla: Imidwebo yamaphepha enezingqimba eziningi imunca umthelela ngenkathi ihlala izinzile kuma-conveyors kanye nezihlungi zamaphasela. Ukuthungwa kwemvelo kwephepha kuphakamisa inani elibonakalayo.

I-Plastic Padded (yokubhoboza ngokweqile noma ingozi yomswakama)

-

Ngaphandle: Ifilimu ye-PE noma i-co-ex (ingafaka I-PCR okuqukethwe)

-

Iphedi yangaphakathi: ifilimu yebhamuza lomoya, ijiyomethri yebhamuza eshuniwe, ukwakheka kwe-anti-slip

-

Izigxivizo: amaphiko abanzi anezinga lokushisa elilawulwayo/ingcindezi yamachopho angavuzi

-

Izengezo: izici eziphazamisayo, ama-strip-strip, amafilimu angaphrinta

Isetshenziswa nini: Izimpahla ezibukhali kakhulu, umswakama ophezulu, noma ukungqubuzana okukhulu ezintweni ezidonsa isikhathi eside lapho ukumelana nokubhoboza kwepulasitiki kubalulekile.

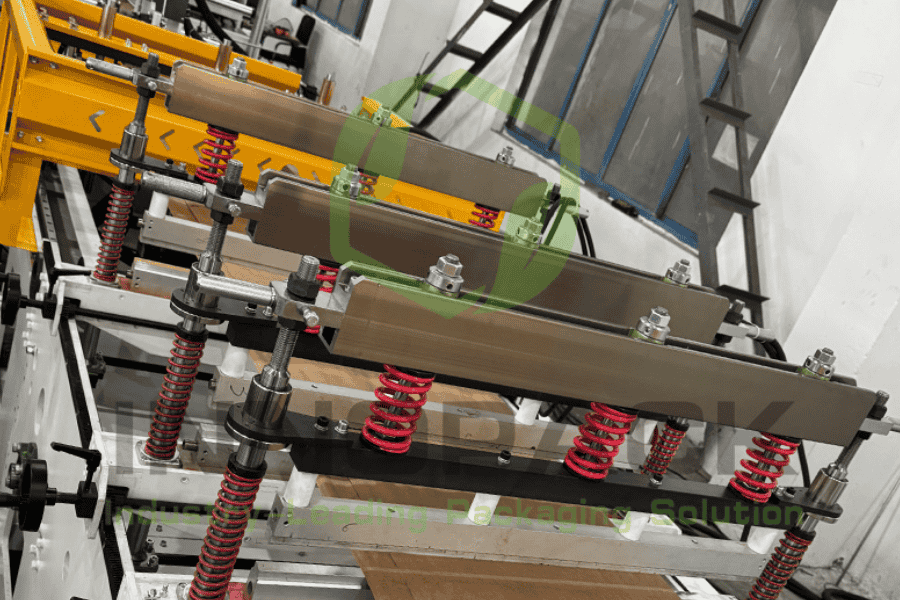

Ubunjiniyela Nenqubo: Umshini Wakha Kanjani Ukuqina

Iziteshi Eziyinhloko Emgqeni Wesimanje

-

Khumula nokulawula iwebhu - Ukuphumula kwe-Servo kanye neziqondiso zewebhu zigcina ukungezwani kuqinile kwephepha noma ifilimu.

-

I-Lamination / Padding Feed - Ifaka i-fiber pad, ishidi lebhamuza lephepha, noma ifilimu yebhamuza ngokubhaliswa okunembile.

-

Ukwakha Nokubeka uphawu - Yakha imiphetho eseceleni/umthungo/egoqiwe; ama-heaters avaliwe bamba amafasitela okuvalwa noma ngokuhlukahluka kwefilimu ye-PCR.

-

Isicelo se-Adhesive/Tear Strip - Ukubekwa kwemigqa okungaguquki ukuze kuvalwe ngokushesha, nokucocekile eziteshini zamaphakethe.

-

Ukuphrinta Kwangaphakathi/Ikhodi/Ilebula - Ilogo, i-QR, amakhodi amaningi/idethi yokuhlolwa kwamabhuku nemithetho yemakethe.

-

Ukuhlola & Ukwenqatshwa - Umbono noma isisindo sibheka amaphutha okubamba uphawu noma amaphutha okubhalisa ngesikhathi sangempela.

-

Ukupakisha nokubala - Izitaki ezilungele ukusetshenziswa zinciphisa isikhathi emabhentshini okupakisha.

Kungani kungcono kunemishini yezimpahla

-

Amalokhi eresiphi nezikrini ze-OEE vimbela ukukhukhuleka, ubambe isivinini ngama-substrates aqinile (amafilimu e-PCR, i-kraft ewugqinsi)

-

Ukuhlanganisa okuzenzakalelayo igcina isikhathi esiphezulu siphezulu; shintsha amasondo ngaphandle kokumisa umugqa

-

Ukuhlola umbono/ingcindezi slash micro-leakers kanye nemichilo engasetshenziswanga kahle edala ukubuyisela

Iphepha vs. I-Plastic Padded Mailers (Ukuqhathanisa Ngokushesha)

| Impahla / Umgomo | Imeyili Ebhalwe Ngephepha | I-Plastic Padded Mailer |

| Ukusebenziseka kabusha (phambi kwendlu) | I-Curbside igaywa kabusha ezimakethe eziningi; ukwamukelwa okuqinile kwabathengi | Iyahlukahluka ngesifunda/ukusakaza; ukubhoboza okuqinile & ukumelana nomswakama |

| Ukuzizwa komkhiqizo (ukukhipha ibhokisi) | I-Premium, I-Aesthetic Enhle, ukubukeka “kwemvelo” | Amafilimu ahlanzekile, acwebezelayo, enziwe ngendlela oyifisayo |

| Ukuqina kwezokuthutha | Phezulu (enephedi/amabhamuza ephepha) | Iphakeme kakhulu (amafilimu ebhamuza lomoya; izimpahla ezibukhali) |

| Ukulandisa kokuhambisana | Iqondana ne-EPR/okuhloswe ukuphinda kusetshenziswe kabusha | Idinga idizayini yokugaywa kabusha nokulebula okucacile |

| Ukusetshenziswa okuvamile | Izingubo, izincwadi, ubuhle, izesekeli, izinhlobo ze-DTC | Ama-elekthronikhi, izingxenye zensimbi, amathuluzi, imizila eswakeme/edonsa isikhathi eside |

Amanethiwekhi amaningi ayasebenza kokubili amafomethi: iphepha leningi, ipulasitiki efakwe ama-SKU afuna ngempela.

Kungani Ibuyisela emuva: Isivinini, Ukunciphisa Ukulimala, kanye “Nenani Lempahla”

-

Isivinini: Amaphekhi esitayela semvilophu ashaya ikhathoni + i-void-fill ngamasekhondi nge-oda ngalinye—afinyelela emahoreni ngokushintshana ngakunye.

-

Isisindo se-DIM esiphansi: Ukujiya nosayizi wesokudla; “ukuthunyelwa emoyeni” okumbalwa.

-

Umonakalo omncane: Ukumuncwa kokushaqeka okubikezelwayo; ubuqotho bonqenqema obungcono = ukubuyisela nezimbuyiselo ezimbalwa.

-

"Yenyusa Inani Lasekhaya" (inani lebhizinisi): Ikhwalithi yophawu oluqinisekisiwe, amalogi okuhlolwa, kanye nemininingwane yephekhi eluhlaza kwandisa inani lamandla yendawo yakho—impahla iba phezulu uma imigqa ingeyesimanjemanje, ihambisana, futhi ibhaliwe.

Umshini Wokwenza Imeyili Ehlanganisiwe

I-Expert Insights & Market Direction

-

Okuthrendayo: Izinkundla zokuthengisa nabathwali baphusha ukupakishwa okungase kusetshenziswe eduze kwe-curbside namalebula angaskena; abathengi baklomelisa i-fiber kuqala lapho kungenzeka khona.

-

Ukubuka kokusebenza: “Ukudizayina ukuze kusetshenziswe kabusha akusho ukuhamba kancane. Cacisa imishini egcina isivinini ku-kraft nokuvula I-PCR ifilimu. Qinisekisa amawindi okuvala futhi ugcine ukulawula kweresiphi kuqinile,” kuphawula unjiniyela omkhulu wezokuthutha ku-EU 3PL ehamba phambili.

-

I-POV yomkhiqizo: Imikhiqizo ye-DTC yobuhle nemfashini ibika amaphuzu aphezulu okubuyekeza kanye nezilinganiso eziphindayo lapho ushintshela ama-mailers anephepha ngenxa yokuzizwa kwe-premium tactile.

Izimpawu zesayensi neze-KPI

-

Seal integrity FPY (First Pass Yield) ≥ 99.5% ngokuhlolwa okusemgqeni

-

Izinga lomonakalo/lokubuyisela ↓ 20–40% vs. ikhathoni + i-generic void fill (okuncike ku-SKU)

-

Okokusebenza +10–25% kusuka ekushintsheni nasekuphatheni ngempumelelo

-

Ukonga isisindo se-DIM kukalwa ngomzila/umzila; buka ukuwina kwesizini ephezulu

-

Okuthandwayo kwabathengi: izinhlolovo zezimakethe eziningi zibonisa ukuvumelana okungaguquguquki kwe-curbside-recyclable kanye nemidwebo efana nephepha ku-e-commerce unboxing

(Sebenzisa okwakho ukuhlolwa kokwehla kwelebhu/3PL, ukuhlola okuqhume, kanye nedatha yomshayeli we-A/B ukuze uqinisekise izimangalo zomkhiqizo kusayithi lakho kanye nama-RFP.)

Ukwenziwa Kwangempela Kwezwe

-

I-Books & Media 3PL (US)

Ishintshele ku ama-mailers anephepha ngo-80% wama-SKU; i-return- due-to-corner-crush iwile 31%; amapaki aphethwe +18% ama-oda shift ngayinye ngemva kokuqeqeshwa.

-

Izimonyo DTC (EU)

Kufakwe uphawu ama-mailers anephepha; ukwaneliseka kwe-unboxing kukhuphuke kanye ne-UGC提及“i-eco & premium”显著增加; ukucwaninga kwemakethe更顺畅.

-

Amathuluzi Nezingxenye Kuthekelisa (APAC → EU)

Ukugcina ama-mailers afakwe epulasitiki ama-SKU abukhali/asindayo; ama-seal aqinisekisiwe ngaphesheya 30% PCR ifilimu ngaphandle kokulahlekelwa isivinini; izikhalazo ezimbalwa zokubhoboza.

Mayelana NATHI :Imishini ye-Innopack ihlanganisa Umshini Wokwenza Imeyili Ehlanganisiwe izixazululo ngaphakathi kwemigqa ebanzi yephepha/yepulasitiki—okuzenzakalelayo, ukuhlola, kanye nesevisi. Hlola okuningi kweyethu Imishini Yokufaka Amaphepha ihabhu.

Impendulo yomsebenzisi

-

"Ukushintshashintsha kusuke emaminithini angama-25 kuye kwayi-8 ngenkumbulo yeresiphi-amahora aphezulu agcina ephefumula." - I-Ops Lead, NL

-

“Abathumeli bezincwadi ezinamaphepha basinike ukubukeka okuhle esikudingayo—izikhalazo zehlisiwe, ziphindaphindeka.” - I-DTC Brand, e-UK

-

"Ukugijima kwefilimu ye-bubble ye-PCR ngesivinini bekuvame ukuba yikhanda elibuhlungu - manje sekuvaliwe futhi ukuhlolwa kwamabhuku kuyadlula." - Umphathi wokupakisha, CA

Ukuthenga Uhlu Lokuhlola

Ukusebenza namafomethi

-

Ububanzi/ibanga lobude bemeyili, izinketho zogqinsi lwephedi, i-specil yokudabula kwezinyembezi

-

Ithagethi yesivinini ekucushweni okunzima kakhulu; okuhloswe ngaso ukushintsha isikhathi

Izinto zokwakha

-

Iphepha: amamaki e-kraft, i-fiber pad / ukuhambisana kwebhamuza lephepha, I-PFAS-mahhala ongakhetha kukho

-

Ifilimu: PE/co-ex, PCR% amawindi, iwindi lokuvala i-DOE ngezingxube zakho

Okuzenzakalelayo & Idatha

-

I-PLC/HMI, izikhiya zokupheka, Ideshibhodi ye-OEE, ukuhlolwa kombono/isisindo, yenqaba ingqondo

-

Ukuphrinta okusemgqeni/ilebula (ilogo, i-QR, izimpawu zokugaywa kabusha eziqondene nesifunda)

Ukuthobelana Nokucwaningwa Kwamabhuku

-

Ukuqondanisa amalebula okusebenziseka kabusha ngokwemakethe

-

Ukulandeleka kweqoqo, amalogi okuhlolwa athekelisa (CSV/API)

Ukusebenza kahle

-

Okuqondiwe kwe-MTBF/MTTR, ukuxilonga okukude, ikhithi yezipele zasendaweni

-

I-FAT/SAT + iphakethe lokuqeqesha opharetha/isondlo

Umshini Wokwenza Imeyili Ohlanganisiwe Wekhwalithi Ephezulu

FAQ

Wenzani i-Padded Mailer Umshini Wokwenza khiqiza?

Izimvilophu ezilungele ukusetshenziswa—iphepha noma ipulasitiki egqinsiwe—ukuthumela ngokushesha, nokuvikela ukuthunyelwa kwe-e-commerce.

Ingabe iphepha ligxunyekwe njengesivikelo njengamabhamuza epulasitiki?

Kuma-SKU amaningi, yebo—amaphedi ephepha ahleliwe noma “amabhamuza” ephepha aletha ukumuncwa okuthembekile okuthembekile. Ezingxenyeni ezicijile/ezisindayo, amapulastiki agqizekile asengawina.

Ngingakwazi ukuphrinta izithonjana zebhrend nezisetshenziswa kabusha kumthumeli weposi?

Yebo. Amamojula wokuphrinta/ilebula asemgqeni engeza amalogo, amakhodi e-QR, namamaki okugaya aqondaniswe nesifunda.

Ingabe izosebenzisa amafilimu e-PCR noma i-kraft ewugqinsi ngaphandle kokwehlisa ijubane?

Ngokulawula kwewindi lokuvala elilungile kanye nokuphathwa kwe-nip, imigqa yesimanje igcina isivinini kukho kokubili.

Ithuthukisa kanjani i-ROI?

Ukupakisha okusheshayo, ukulimala okumbalwa, isisindo se-DIM esiphansi, nokuhlola okushelelayo—kanye nokuzizwisa kwekhasimende okuyi-premium okuthuthukisa ama-oda aphindayo.

Imvilophu Ehlakaniphe Kakhulu Oyoke Uyithumele

A Umshini Wokwenza Imeyili Ehlanganisiwe iguqula ukupakishwa kusuka esikhungweni sezindleko kuya injini yokusebenza: imigqa esheshayo, umonakalo omncane, izifakazelo eziluhlaza okotshani, kanye nesikhashana se-premium unboxing esibonwa ngamakhasimende. Ukuthi uhola nge ama-mailers anephepha ukuze kusetshenziswe kabusha nokuzwakala komkhiqizo, noma gcina ama-mailers afakwe epulasitiki kuma-SKU aqine kakhulu, ukhiye umshini ophethe isivinini, ubuqotho bophawu, kanye nedatha yokuhlola—njalo ngoshintsho olulodwa. Yileyo ndlela ovikela ngayo yomibili imikhiqizo futhi i-P&L.

Ukupakishwa komhlaba wonke kuhlangana eqinisweni elifanayo lokusebenza: izimvilophu ezihlakaniphe kakhulu yilezo umugqa wakho ongazenza ngokushesha, zibhale ngokucacile, futhi zigaywe kabusha kalula. I-PPWR yase-Europe yaqala ukusebenza ngo-Feb 11, 2025, yaqala ukusebenza ngemva kwezinyanga ezingu-18—ukufaka amakhodi kanzima “okungaphinde kusetshenziswe ngokuklama” kanye nokuthotshelwa kwedatha okucebile ezinqumweni zokupakisha zansuku zonke. ENyakatho Melika, izimpawu zokutshalwa kwezimali zisebenza ngendlela efanayo: I-PMMI ibika ukuthi ukuthunyelwa kwemishini yase-U.S. igcizelela lokho okuzenzakalelayo nge-ROI elinganisekayo ngesivinini.

Futhi ezingeni lesikhulumi, ukususwa kwe-Amazon kwe-95% yemicamelo yomoya yepulasitiki kuvumela isigcwalisi sephepha kukhombisa ukuthi i-fiber-forward cushioning ingahlangabezana nezinhloso zokuvikela esikalini-umongo obalulekile lapho ukhetha amafomethi anamaphepha.

Ngobuchule, lezi zinyathelo zihambisana nomgwaqo we-UNEP: ukuklama kabusha, ukuphinda kusetshenziswe, futhi kusetshenziswe kabusha kunganqamula ukungcoliswa kwepulasitiki kufikela ku-80% ngo-2040 uma imboni nenqubomgomo kuhlangana ndawonye—ngokufanayo amaleveli anikwe amandla abathumeli be-imeyili abasayizi kwesokudla, abangaphinde basetshenziswe futhi basebenzise imishini elungele ukuhlolwa.

Umugqa ongezansi: Umshini Wokwenza Umeyili Ohlanganisiwe ogcina isivinini kumafilimu e-kraft nawe-PCR, amaresiphi okhiye wokuvala, futhi othumela ngaphandle ubufakazi bezinga lenqwaba uzovikela imikhiqizo—kanye ne-P&L. Uma udinga ipulani eyakhelwe kuleyo miphumela, izixazululo ezididiyelwe zika-Innopack ziklanyelwe ukuthunyelwa ngokushesha, zephule kancane, futhi ziphumelele ukuhlolwa kokuzama kokuqala.