Inkulumompikiswano ye-Boardroom on Going Paper

"Ithimba, ibhodi lifuna ukuncishiswa kwepulasitiki kanye nokuhlolwa kwamabhuku okusheshayo. Yini ephukayo uma sishintsha?"

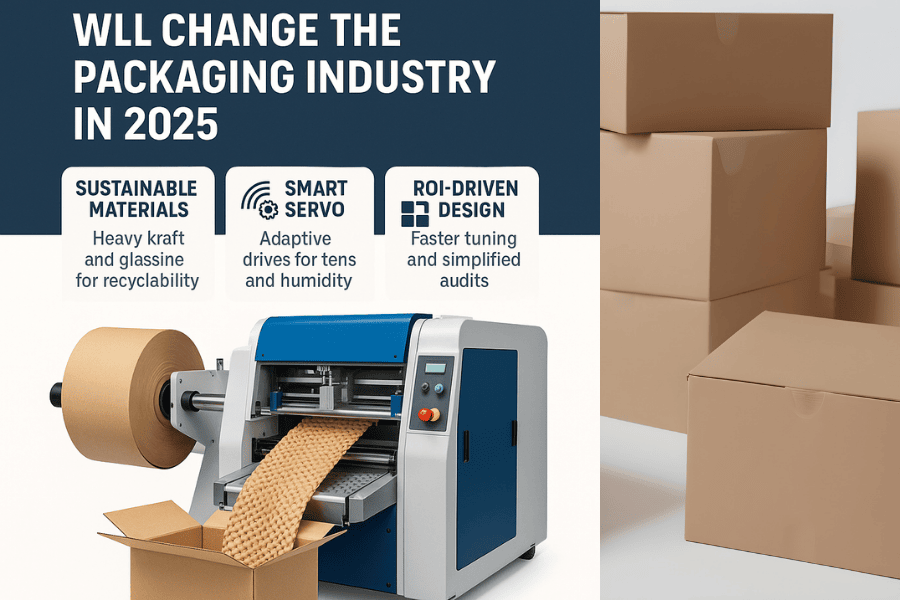

“Akukho lutho—uma sicacisa umshini ofanele wephepha,” kuphendula unjiniyela wokufaka izinto. "Amasistimu weposi wesimanje wephepha, ibhamuza, namasistimu okugoqa asebenza njengokucindezela okunembayo. I-Servo ishayela ukungezwani kokuvumelanisa, amashuni okuvala aguquguqukayo omswakama, futhi amakhamera aqinisekisa wonke umthungo. Sizogcina isivinini futhi sizuze ikhredithi ye-ESG."

Lokho kushintshana kudlala nsuku zonke kusuka kuma-e-commerce hubs kuya ku-3PLs. Umbuzo awusekho uma iphepha lingathatha indawo yezingxenye zepulasitiki noma ama-mailers-kunjalo indlela yokufaka imishini yephepha ngaphandle kokulahlekelwa ukusebenza kahle noma ukuvikela. Impendulo: tshala emishinini eyakhelwe ukuphatha amaphepha aqinile, i-QA ezenzakalelayo, kanye nemizila yedatha elungele ukuhlolwa.

Imishini Yokufaka Amaphepha

Okubalulekile Njengemishini Yokufaka Iphepha

Imishini ye-Glassine/Kraft Mailer — ifomu, goqa, i-glue/heat-seal, phrinta, nezimvilophu ze-batch-log.

Imishini Yebhamuza Yomoya Yephepha — Dala izakhiwo zephepha “zebhamuza” zokugoqa/ukugcwalisa okuyize.

Imishini Yomcamelo Yomoya Yephepha - vuthela futhi uvale imicamelo usebenzisa ama-web wephepha angasebenza kabusha.

Imishini yokugoqa — amaphedi asonga abalandeli, izivikeli ezinqenqemeni, nezinto ezifakwayo ezinokunemba okungu-±0.1–0.2 mm.

Imigqa Yamaphekhi Abalandeli-Fold - khiqiza amaphedi aqhubekayo eziteshi zokupakisha ezizenzakalelayo.

Imigomo eyabiwe: okokufaka okungaphinda kusetshenziswe, ama-seam ahlala isikhathi eside, isikhathi esiphezulu, ukuthobelana kalula, ubuhle be-premium unboxing.

Ukuqhathanisa Ngokushesha

| Imibandela | Amasistimu Wokupakisha Amaphepha | Ezivamile Plastic Systems |

| Ukuhambisana nokucwaningwa kwamabhuku | Ama-SKU agaywa kabusha ngokwemvelo; imibhalo elula yamahhala ye-PFAS | Izinhlaka ezivuthiwe; amakhodi wezinto ezibonakalayo kanye nemininingwane |

| Ukuqina | Ukugoqa/imithungo okuqinisiwe, ukuchotshozwa konqenqema oluqinile nge-GSM engakwesokudla | I-cushion efakazelwe isikhathi eside yezimpahla ezicijile/ezintekenteke |

| Ibhrendi ne-CX | Indaba "eyehlisiwe ngepulasitiki"; ukubukeka kwe-premium kraft/glassine | Ukubukeka/umuzwa ojwayelekile; ongakhetha ifilimu ebanzi |

| Impahla/DIM | Ijometri yeseli ethuthukisiwe ivamise ukwehlisa amanani e-DIM | Izinzile, ukuminyana kwezinto ezibonakalayo |

| Abashayeli bezindleko | Isivuno sezinto ezibonakalayo, ukusebenza kahle kwamandla, ukubuyisela okumbalwa | Ukusebenza okuphezulu, ukutholakala kwefilimu ebanzi |

Ukudla okudlela endlini: yomibili imindeni ibalulekile. Khetha nge Iphrofayili yengozi ye-SKU, Audit landscape, futhi ezomnotho wezimpahla, hhayi ukulandisa kosayizi owodwa.

Imishini Yethu Yokupakisha Amaphepha: Izinto Zokusebenza Nezinqumo Zomklamo Ezibalulekile

Izinto esizilungiselelayo

I-Kraft (60–160 GSM): ukuqina okuphezulu, inkumbulo egoqekayo enhle kakhulu, ephrintekayo yomkhiqizo/amakhodi.

Ingilazi: kuyashintshashintsha, kuminyene, kubushelelezi kwabathumeli be-premium kanye nokufundeka kwelebula.

I-Barrier & coatings esekwe emanzini: ukulinganisela komswakamo ngenkathi kusasebenza kabusha.

Ama-Adhesives & sealing: amathuluzi okuncibilika okushisayo kanye ne-heat-seal, ashunwe ngokwekhemistri yephepha ngalinye.

Mechanical & control architecture

Ukunyakaza kwe-All-servo ngokubhaliswa kwedijithali kwezikolo ezigoqekayo, ama-gussets, nama-flaps.

Ukungezwani kweluphu evaliwe izinzwa kuyo yonke indawo yokuphumuza/ukunqwabelana/ukubuyisela emuva ukuvimbela imibimbi emincane.

Ukuvalwa kwe-Adaptive (PID) igcina ingcindezi yokuhlala kanye ne-nip ihambisana kuwo wonke ama-GSM swing.

Ukuhlolwa kwe-in-line: amakhamera wendawo + izinzwa zomphetho zobuqotho bomthungo, ubukhona beglue, ukunemba kokugoqa.

I-HMI ye-opharetha yokuqala: imitapo yolwazi yamaresiphi, izangoma zokushintsha, amadeshibhodi e-SPC, namalogi omcimbi.

Kungani lokhu kudlula imishini “ejwayelekile”

Ukunemba: ±0.1–0.2 mm ukugoqa/ukubekwa kophawu vs. ±0.5 mm egiyeni lefa.

Veza: izindlela zommese ezithuthukisiwe nezakhiwo ezibekwe esidlekeni zehlisa ukulahleka kokusika ngo-2–5%.

Isikhathi esiphezulu: amafulegi okulungisa abikezelayo anokushisa, ukukhukhuleka komthwalo wedrayivu, nokudidayo kwezimpawu ezinsukwini ezedlule.

Amandla: amabhulokhi okuvalwa okushisa okuphansi namandla okusika okungenzi lutho afika ku-15–20% uma kuqhathaniswa nezisekelo ezingu-2020.

Imishini yethu Yokupakisha Amaphepha: Inqubo, i-QA, kanye Nokwethenjelwa

Ukugeleza kokukhiqiza sincoma

-

I-IQ yezinto ezibonakalayo: qinisekisa i-GSM, amandla e-MD/CD, umswakama, nesisindo sejazi.

-

Ukuvalwa kweresiphi: Izinzwa eziqinisekiswe i-MSA, ibanga lokuvala lesampula legolide, okuqondiwe kwesisindo seglue.

-

Ukugijima komshayeli: ukuhlolwa kwengcindezi yehora lonke kuwo wonke amafasitela alingisa umswakamo/izinga lokushisa.

-

Isisekelo se-OEE: isivinini seshadi lokugijima, ukutholakala, ikhwalithi (≥ 92–95% ehamba phambili ekilasini).

-

Ikhithi yokuhlola: ama-ID weqoqo, izinga lokushisa elivaliwe, iglue amagremu/m², ukuhlola opharetha, izithombe zekhamera.

Amamethrikhi e-QC esiwashicilelayo

Ikhasi le-Seam: okuqondiwe ≥ 3.5–5.0 N/25 mm (kuncike ekilasini lomthumeli).

I-Burst & edge crush: hlangabezana noma weqe ama-threshold aqondene ne-SKU.

Ukunemba kobukhulu: ± 0.2 mm kumafolda abalulekile; ±0.3 mm kokusikwa.

Faka ilebula yokuqhathanisa/amazinga okufunda kumafasitela engilazi ≥ 99.5%.

Ukuzinza kwe-Run-to-run: CpK ≥ 1.33 yobukhulu obuyinhloko kumashifu wamahora angu-8.

Umuzwa womsebenzi

8–12 imiz izinguquko zokupheka nge-auto-threading kanye namathuluzi akhipha ngokushesha.

Umbala we-HMI nezihlahla zamaphutha namazwibela evidiyo avela kumakhamera ukuze axazulule izinkinga ngokushesha.

Ukuphepha: Amasekhethi e-CAT-3, amakhethini alula, ama-interlock, ama-e-stop ngokwenkambiso ye-EN/UL.

Imishini Yokupakisha Yekhwalithi Ephezulu

Izinzuzo Eziphezulu Eziyi-10 Zokushintshela Emshinini Wokupakisha Wamaphepha

-

Ukusebenziseka kabusha ngosuku lokuqala: ukuhlunga okulula, izimangalo ezilula.

-

Ukonga impahla kanye ne-DIM: ibhamuza lephepha/ijiyomethri yomcamelo inciphisa izindleko zevolumu kuma-SKU amaningi.

-

Ukuqina nedatha: amandla omthungo aqinisekisiwe kulayini—akukho ukuqagela.

-

Umuzwa womkhiqizo we-Premium: Izindawo ze-kraft/glassine ziphakamisa inani elibonakalayo.

-

Isivinini sokucwaningwa kwamabhuku: Izimemezelo zamahhala ze-PFAS nezibuyekezo ze-batch logs ngesivinini se-EPR/PPWR.

-

Ukusebenza kahle kwamandla: ukuvala ukushisa okuphansi + ukungenzi lutho okuhlakaniphile kunciphisa amayunithi we-kWh/1000.

-

Izimbuyiselo eziphansi: ama-cushions angaguquguquki nokulingana kusho ama-scuffs/ama-crush ambalwa.

-

Ukuvumelana nezimo kwama-SKU: izindlela zokupheka zishintsha i-GSM, okokunamathela, nezakhiwo ngokushesha.

-

Izinzuzo zasemsebenzini: imigqa emile kancane, ehlanzekile, ukugeleza kwe-scrap ecacile.

-

Ubufakazi besikhathi esizayo: iqondaniswe nokwandisa iziyalezo zephepha/zokusebenzisa kabusha.

Ulwazi Lochwepheshe

U-Sarah Lin, Amathrendi we-ArchDaily (2024): “Imishini yokupakisha yamaphepha ihambisana nezinqubomgomo zomhlaba zokunciphisa ipulasitiki. Abazokwamukela kusenesikhathi bavaleleka ekuthobeleni nasekuphakanyisweni komkhiqizo.”

UDkt. Emily Carter, MIT Materials Lab (2023): "I-Glassine ne-kraft, kucutshungulwe ngaphansi kokulawulwa kwe-servo, kufanisa ama-cushions epulasitiki ukuze aqine ekuhlolweni kokuwa nokucindezelwa kwezinsimbi."

Umbiko Womkhakha we-PMMI (2024): “Ukuthunyelwa kwemishini yokupakisha kudlule u-$10.9B; amasistimu asekelwe ephepheni ayingxenye ekhula ngokushesha kakhulu.”

Idatha Yesayensi

Okuthandwayo kwabathengi: Izinhlolovo ze-EU (2023) zibonisa ~85% khetha ukupakishwa okugaywa kabusha; ~62% hlanganisa abathumeli bephepha nemikhiqizo ephambili.

Ukusebenza kokugaya kabusha: Amanani okusebenzisa kabusha amaphepha ajwayelekile > 68% ezimakethe ezithuthukile; iziqukathi/ukupakishwa kuhlala kuwumfudlana omkhulu kunawo wonke (EPA 2024).

Ukusebenza kahle kwe-Logistics: Ukushintshela ku-cushion yephepha kuncishisiwe I-DIM ishaja kufika ku-~14% kubashayeli bezindiza abalawulwayo (I-Journal of Sustainable Logistics, 2023).

Izimpawu ze-Capex: Imishini eqondiswe ekusimameni kulindeleke ukuthi imele ~45% ye-capex yokupakisha ngo-2027 (imibono yamafemu amaningi).

Sebenzisa izimo kanye nokuzilolonga ngesandla

Izimpahla Ze-E-Commerce (I-Mailer + Ibhamuza Lephepha)

Isenzo: Kushintshwe ama-mailers epulasitiki afakwe ama-kraft/glassine mailers; wengeze amaseli okugoqa amabhamuza ephepha ukuze kuncishiswe izinto ezithambile.

Umphumela: 18% izimbuyiselo ezimbalwa ezihlobene ne-scuff; ukubuyekezwa kwekhasimende kucaphuna "i-premium, i-eco packaging."

Umsabalalisi Wezincwadi (Ukugoqa + Amaphedi Agoqe Ngabalandeli)

Isenzo: Ama-kraft pads afakwe phakathi kwama-spines namasembozo; onogada bakhona abagoqe ngokuzenzakalelayo.

Umphumela: 12% ukunciphisa i-DIM; ikhwalithi yokufika ethuthukisiwe kumakhava aqinile.

Izinsiza zikagesi (Isu leHybrid)

Isenzo: Abathumeli bephepha bama-SKU aqinile; ukugoqa kwebhamuza lephepha elijiyile kumamodeli abucayi.

Umphumela: Izindleko ezilinganiselwe kanye nokuvikelwa; Izimangalo ze-ESG ziqinisekisiwe; i-warehouse igcinwe i-fiber-stream recycling kabusha.

Impendulo yomsebenzisi

"Izindleko ze-DIM zehle izinombolo eziphindwe kabili ku-Q1." - Logistics Manager

"Ukwehluleka komthungo kunyamalale ngemuva kokushintshela emigqeni yephepha le-servo." - Ikhanda le-Ops

"Ukucwaningwa kwamabhuku manje sekuphelile ngezinsuku, hhayi amasonto - ama-batch logs ashintshe umdlalo." - Umqondisi Wokuthobela

Abahlinzeki Bemishini Yokupakisha Amaphepha

FAQ

Ingabe amakhushini ephepha avikela njengepulasitiki?

Nge-GSM efanele kanye nejometri yeseli, amasistimu ebhamuza/umcamelo wephepha afinyelela ukumuncwa komthelela nokuthola ukucindezelwa okuqhathaniswa namafomethi amaningi e-LDPE—okugunyazwe yi-in-line QA kanye nokuhlolwa kwelebhu yezikhathi ezithile.

Ingabe umugqa owodwa ungaphatha i-kraft ne-glassine?

Yebo. Ukulawulwa kwe-servo yamaresiphi amaningi kulawula ukungezwani, i-nip, nokulungiswa kwezinga lokushisa phakathi kwezinto ngokuzenzakalela.

Iyini i-ROI evamile?

Ngevolumu ephakathi ukuya phezulu, 6-18 izinyanga iqhutshwa i-DIM ephansi, ukubuyisela okumbalwa, kanye nokwehliswa kwezihloko zokuhlola ezincishisiwe.

Siziqinisekisa kanjani izimangalo zokuphinda zisetshenziswe?

Sebenzisa imibhalo yomthengisi kanye nemibiko yokuhlola evela eceleni; fanisa izithonjana/kopisha kuwo wonke ama-SKU futhi ulondoloze amalogi enqwaba.

Ingabe amasistimu wephepha aphakamisa ukusetshenziswa kwamandla?

Akunjalo. Ukuvalwa kokushisa okuphansi, ukulinda okuhlakaniphile, nezindlela zewebhu ezilungiselelwe kaningi nciphisa kWh ngamayunithi ayi-1000 uma kuqhathaniswa nezisetshenziswa ezindala.

Izithenjwa

-

USarah Lin - "Amathrendi Wokupakisha Wemishini Yezinto Ezisimeme," i-ArchDaily Trends, 2024.

-

U-Emily Carter, PhD — “Ukuqina Kwephepha vs. I-Polymer Cushions Ngaphansi Kokucubungula Kwe-Servo,” MIT Materials Lab, 2023.

-

I-PMMI - "Ukupakisha Ukuthunyelwa Kwemishini Nokukhula Kwengxenye 2024," Umbiko we-PMMI, 2024.

-

I-EPA — “Iziqukathi Nokupakishwa: Isizukulwane Nokugaywa Kabusha Kwe-Metrics 2024,” U.S. EPA, 2024.

-

Ikhomishini ye-EU — “Ukubuka konke Kokulawulwa Kokupakisha Nokufakwa Kwemfucuza (PPWR),” 2024–2025.

-

Ijenali ye-Sustainable Logistics — “I-DIM Weight Reduction nge-Paper Cushioning Systems,” 2023.

-

Ijenali ye-Industrial Automation — “Ukuvumelanisa Kwe-Servo Nokugcinwa Okubikezelwe Kolayini Abaguqulayo,” 2023.

-

I-McKinsey - "I-Outlook yokupakisha eqhubekayo: I-Capex Shifts Kuze kube ngu-2027," ngo-2025.

-

I-World Packaging Organization - "Ukwamukelwa Kwezinto Ezingasetshenziswa Kabusha Ku-E-Commerce Packaging," 2024.

-

Ithimba Lezobuchwepheshe Le-InnopackMachinery — “Imigqa Yokufaka Iphepha Elilungele Ukucwaningwa Kwamabhuku: Ukubekwa uphawu, i-QA, ne-OEE,” Iphepha Elimhlophe, 2025.https://www.innopackmachinery.com/