ស្វែងយល់ពីរបៀបដែលម៉ាស៊ីនបត់ជំនាន់ក្រោយកំណត់ឡើងវិញនូវប្រសិទ្ធភាព និងនិរន្តរភាពនៅឆ្នាំ 2025។ ស្វែងយល់អំពីស្វ័យប្រវត្តិកម្ម servo ការច្នៃប្រឌិតសម្ភារៈ ការវេចខ្ចប់អេកូ និងនិន្នាការ ROI ដែលបង្កើតឧស្សាហកម្មម៉ាស៊ីនបត់ទំនើប។

សង្ខេបខ្លី៖ នៅពេលដែលឧស្សាហកម្មវេចខ្ចប់ផ្លាស់ប្តូរឆ្ពោះទៅរកស្វ័យប្រវត្តិកម្ម និងនិរន្តរភាព បច្ចេកវិទ្យា Folding Machine បានក្លាយជាមូលដ្ឋានគ្រឹះនៃផលិតកម្មប្រកបដោយប្រសិទ្ធភាព និងប្រកបដោយប្រសិទ្ធភាព។ មិនថានៅក្នុង e-commerce, paper mailers, or logistics នោះទេ ប្រព័ន្ធបត់ដែលគ្រប់គ្រងដោយ servo នាពេលបច្ចុប្បន្ននេះមានតុល្យភាពរវាងភាពធន់ ភាពជាក់លាក់ និងការច្នៃប្រឌិតពណ៌បៃតង។ ការណែនាំនេះស្វែងយល់អំពីសម្ភារៈ ការកែលម្អដំណើរការ ការយល់ដឹងពីអ្នកជំនាញ និងនិន្នាការឆ្នាំ 2025 ដែលបង្ហាញពីអនាគតនៃម៉ាស៊ីនបត់។

ការសន្ទនាដែលកំណត់អនាគត "តើអ្នកនៅតែដំណើរការបន្ទាត់បត់ដោយដៃទេ?"

នៅឆ្នាំ 2025 ស្វ័យប្រវត្តិកម្ម ប្រសិទ្ធភាពថាមពល និងនិរន្តរភាពបានកំណត់ឡើងវិញពីរបៀបដែលអ្នកផលិតបត់ កាត់ និងផ្សាភ្ជាប់សម្ភារៈ។ ក ម៉ាស៊ីនបត់ទំនើប មិនមែនគ្រាន់តែជាជំនួយមេកានិកទៀតទេ - វាគឺជាទ្រព្យសម្បត្តិផលិតកម្មដែលជំរុញដោយទិន្នន័យដែលរួមបញ្ចូលការត្រួតពិនិត្យ AI ការធ្វើសមកាលកម្ម servo និងប្រតិបត្តិការគ្មានកាកសំណល់។

មគ្គុទ្ទេសក៍នេះពន្យល់ពីមូលហេតុដែលការអាប់ដេតទៅបច្ចេកវិទ្យាបត់ជំនាន់ក្រោយផ្តល់នូវទាំងពីរ ភាពធន់នៃប្រតិបត្តិការ និង ROI យុទ្ធសាស្ត្រ នៅក្នុងទីផ្សារដែលមានការប្រកួតប្រជែងកាន់តែខ្លាំងឡើង។

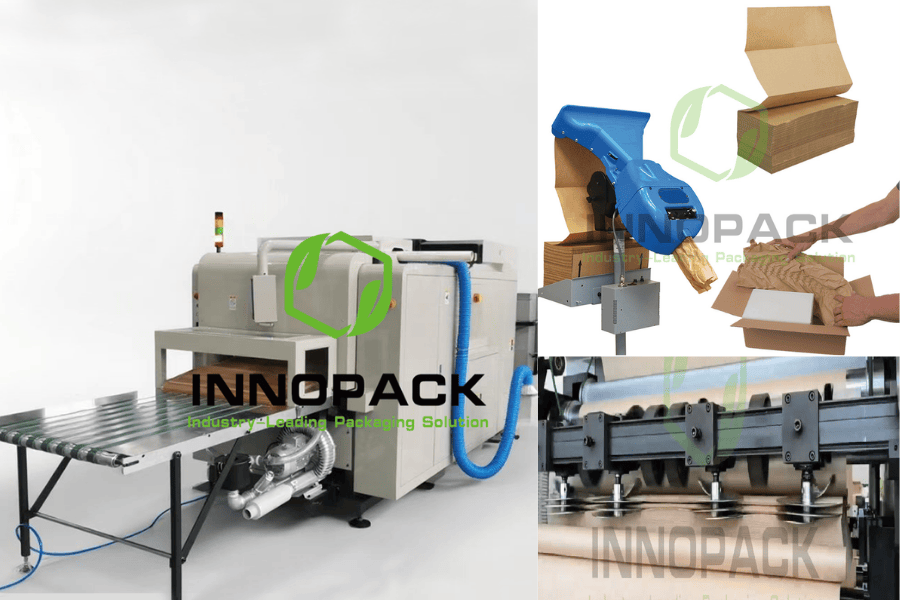

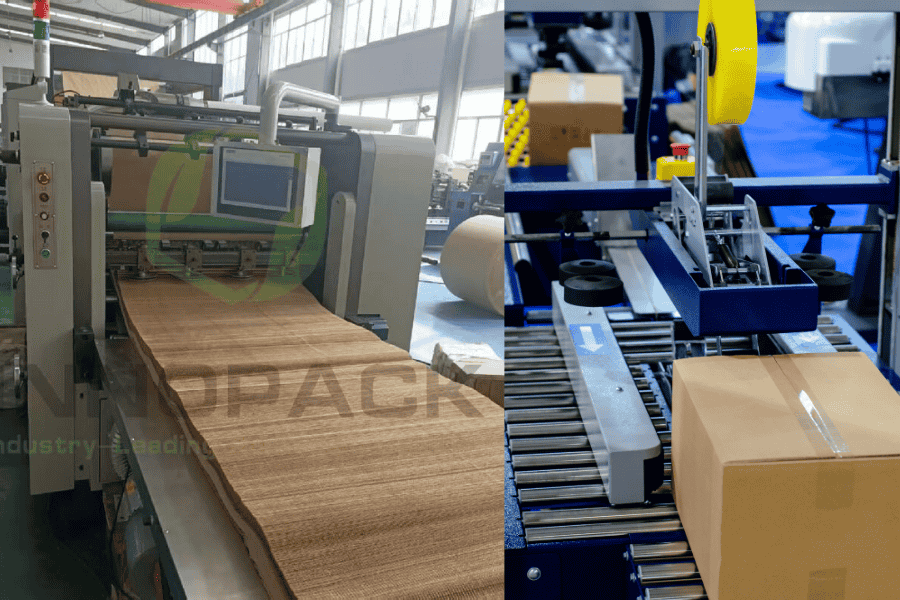

ម៉ាស៊ីនបត់

ការវិវត្តន៍នៃការបត់ ម៉ាស៊ីន Te បច្ចេកវិទ្យា ពី rollers មេកានិចសាមញ្ញទៅប្រព័ន្ធ servo-folding ដោយស្វ័យប្រវត្តិយ៉ាងពេញលេញ ម៉ាស៊ីនបត់ បានឆ្លងកាត់ការផ្លាស់ប្តូរយ៉ាងខ្លាំង។

ចំណុចសំខាន់ មុនឆ្នាំ 2010៖ ការបត់មេកានិចជាមួយនឹងប្រអប់លេខថេរ ការថែទាំខ្ពស់ ភាពបត់បែនទាប។

2015-2020៖ ប្រព័ន្ធ Servo បានណែនាំការគ្រប់គ្រងចលនាច្បាស់លាស់។

២០២៥៖ ការរួមបញ្ចូលគ្នានៃ AI និង IoT អនុញ្ញាតឱ្យមានការថែទាំតាមព្យាករណ៍ មតិត្រឡប់តាមពេលវេលាជាក់ស្តែង និងការតាមដានសម្ភារៈឆ្លាតវៃ។

ហេតុអ្វីបានជាការវិវត្តនេះសំខាន់ ថ្ងៃនេះ ម៉ាស៊ីនបត់ ធ្វើអោយប្រសើរឡើងនូវទិន្នផលសម្ភារៈ កាត់បន្ថយពេលវេលារៀបចំរហូតដល់ 40% និងការគាំទ្រ ស្រទាប់ខាងក្រោមក្រដាសដែលមិនប៉ះពាល់ដល់បរិស្ថាន ស្របតាមបទប្បញ្ញត្តិនិរន្តរភាពសកល។

ការជ្រើសរើសសម្ភារៈ និងការរចនាវិស្វកម្ម សមាសធាតុកម្រិតខ្ពស់ ម៉ាស៊ីនទំនើបប្រើ៖

យ៉ាន់ស្ព័រដែលមានភាពជាក់លាក់ - ធានាបាននូវស្ថេរភាពរយៈពេលវែង និងសម្ពាធបត់ជាប់គ្នា។

ប្រព័ន្ធត្រួតពិនិត្យ Servo-Driven - ធ្វើសមកាលកម្មល្បឿនបត់ និងភាពតានតឹងសម្រាប់ការរចនាស្មុគ្រស្មាញ។

ឧបករណ៍ចាប់សញ្ញាឆ្លាតវៃ - រកមើលការប្រែប្រួលនៃកម្រាស់ក្រដាស ដើម្បីការពារការកកស្ទះ ឬផ្នត់។

ធ្វើឱ្យប្រសើរសម្រាប់និរន្តរភាព ភាពឆបគ្នានៃក្រដាស Kraft និង Glassine

ការផ្សាភ្ជាប់កំដៅទាប ប្រព័ន្ធកាត់បន្ថយការប្រើប្រាស់ថាមពល។

Closed-Loop Feedback សម្រាប់ការកាត់បន្ថយសំណល់។

ហេតុអ្វីបានជាវាដំណើរការជាងប្រព័ន្ធធម្មតា។ លក្ខណៈ ម៉ាស៊ីនបត់ទំនើប គំរូប្រពៃណី ការគ្រប់គ្រង Servo ភាពត្រឹមត្រូវតាមពេលវេលាជាក់ស្តែង ± 0.1mm ការលៃតម្រូវប្រអប់លេខដោយដៃ ជួរសម្ភារៈ Kraft, ស្រោប, ក្រដាស glassine កំណត់ចំពោះកម្រាស់ឯកសណ្ឋាន ការថែទាំ ការទស្សន៍ទាយនិងឌីជីថល មេកានិចនិងប្រតិកម្ម ល្បឿនបញ្ចេញ រហូតដល់ 150 ម៉ែត / នាទី។ 60-80 ម / នាទី។ និរន្តរភាព សន្សំសំចៃថាមពល អាចប្រើឡើងវិញបាន។ ថាមពលនិងការបាត់បង់សម្ភារៈកាន់តែខ្ពស់។

ដំណើរការផលិត និងការច្នៃប្រឌិតក្នុងឆ្នាំ 2025 បច្ចេកទេសផលិតកម្មកម្រិតខ្ពស់

ការផលិតភាពជាក់លាក់ CNC៖ ធានាការតម្រឹមជាប់គ្នា និងកាត់បន្ថយរំញ័រ។

ការក្រិតតាមខ្នាតបត់ដោយឡាស៊ែរ៖ ផ្តល់លទ្ធផលស្អាត ដែលអាចធ្វើម្តងទៀតបានសម្រាប់ផ្នត់ស្មុគស្មាញ។

ចំណុចប្រទាក់គ្រប់គ្រងឌីជីថល (HMI)៖ អនុញ្ញាតឱ្យប្រតិបត្តិករកែតម្រូវការបត់ មុំ និងល្បឿនបណ្តុំភ្លាមៗ។

សមាហរណកម្មឆ្លាតវៃ

ឥឡូវនេះប្រព័ន្ធទាំងនេះរួមបញ្ចូល ការធ្វើរោគវិនិច្ឆ័យដោយ AI ដែលអាចណែនាំដោយស្វ័យប្រវត្តិនូវការកែតម្រូវ តាមដានគំរូនៃការពាក់ និងរក្សាទុកការវិភាគផលិតកម្ម - ជួយឱ្យរោងចក្ររក្សា OEE (ប្រសិទ្ធភាពឧបករណ៍រួម) លើសពី 95% ។

ម៉ាស៊ីនបត់ក្រដាស

ការយល់ដឹងពីអ្នកជំនាញ សារ៉ាលីន , ការវេចខ្ចប់ថ្ងៃនេះ (២០២៤)៖

"ស្វ័យប្រវត្តិកម្មម៉ាស៊ីនបត់គឺជាវីរបុរសនៃការដឹកជញ្ជូនបៃតង។ វាភ្ជាប់ប្រសិទ្ធភាពជាមួយនឹងការកែច្នៃឡើងវិញ ដែលជាចំនុចប្រសព្វដែលកំណត់អនាគតនៃការវេចខ្ចប់។"

វេជ្ជបណ្ឌិត Emily Carter , MIT Materials Lab (២០២៣)៖

"ប្រព័ន្ធផ្នត់ដែលមានមូលដ្ឋានលើ Kraft មានប្រសិទ្ធភាពជាងស្រទាប់ផ្លាស្ទិចក្នុងភាពធន់នឹងសំណើម នៅពេលដែលរួមបញ្ចូលគ្នាជាមួយនឹងការក្រិតត្រាត្រឹមត្រូវ"។

របាយការណ៍ឧស្សាហកម្ម PMMI (2024)៖

ការនាំចេញម៉ាស៊ីនបត់ដែលមានមូលដ្ឋានលើក្រដាសបានកើនឡើង 18% ពីមួយឆ្នាំទៅមួយឆ្នាំ ធ្វើឱ្យវាក្លាយជាប្រភេទឧបករណ៍វេចខ្ចប់ដែលរីកលូតលាស់លឿនបំផុតមួយ។

ទិន្នន័យវិទ្យាសាស្ត្រ និងម៉ែត្រនៃឧស្សាហកម្ម បទប្បញ្ញត្តិការវេចខ្ចប់របស់សហភាពអឺរ៉ុប (2024)៖ ម៉ាស៊ីនវេចខ្ចប់ក្រដាស ការអនុម័តដោយ 25% នៅអឺរ៉ុបដោយសារតែការអនុលោមតាម EPR (ការទទួលខុសត្រូវរបស់អ្នកផលិតបន្ថែម) ។

ការសិក្សា EPA (2023)៖ សំបុត្រក្រដាសដែលអាចកែច្នៃឡើងវិញបានកាត់បន្ថយការបំភាយឧស្ម័ន CO₂ ដោយ រហូតដល់ 32% ធៀបនឹងការវេចខ្ចប់ប្លាស្ទិក។

ទិនានុប្បវត្តិនៃការផលិតប្រកបដោយនិរន្តរភាព (2025)៖ របាយការណ៍បន្ទាត់បត់ដោយស្វ័យប្រវត្តិ 20–28% ដំណើរការឡើងវិញផលិតផលតិចជាងមុន និងធ្វើអោយប្រសើរឡើងនូវភាពត្រឹមត្រូវនៃការវេចខ្ចប់។

ករណីសិក្សា៖ ផលប៉ះពាល់ពិភពលោកពិត មជ្ឈមណ្ឌលបំពេញតាមអេឡិចត្រូនិក ប្តូរពីការបត់ដោយដៃទៅប្រព័ន្ធបត់ក្រដាសដែលគ្រប់គ្រងដោយ servo ។លទ្ធផល៖ ល្បឿនវេចខ្ចប់លឿនជាង 30% កាកសំណល់សម្ភារៈតិចជាង 22% ធ្វើអោយប្រសើរឡើងនូវ ergonomics ។

ផលិតកម្មប្រណិតប្រណិត ទទួលយកកញ្ចក់ ម៉ាស៊ីនបត់ក្រដាស លទ្ធផល៖ កែលម្អសោភ័ណភាពម៉ាកជាមួយនឹងអ្នកផ្ញើសំបុត្រដែលអាចប្រើឡើងវិញបានពេញលេញ។

អ្នកផ្តល់សេវាភស្តុភារភាគីទីបី ប្រព័ន្ធត្រួតពិនិត្យ និងបត់ឌីជីថលរួមបញ្ចូលគ្នា។លទ្ធផល៖ កាត់បន្ថយការបត់ខុសចំនួន 18% និងសម្រេចបាននូវការតាមដានដែលអនុលោមតាម ISO ។

មតិអ្នកប្រើ "ពេលវេលារៀបចំបានធ្លាក់ចុះពាក់កណ្តាល ហើយវិក្កយបត្រថាមពលបានធ្វើតាម។" - អ្នកគ្រប់គ្រងផលិតកម្ម រោងចក្រ EU

អ្នកផ្គត់ផ្គង់ម៉ាស៊ីនបត់

សំណួរគេសួរញឹកញាប់ តើអ្វីជាអត្ថប្រយោជន៍ចម្បងនៃម៉ាស៊ីនបត់ទំនើប?

តើប្រព័ន្ធបត់ក្រដាសគាំទ្រគោលដៅនិរន្តរភាពយ៉ាងដូចម្តេច?

តើអាយុកាលរបស់ម៉ាស៊ីនបត់ដែលគ្រប់គ្រងដោយ servo គឺជាអ្វី?

តើម៉ាស៊ីនបត់អាចគ្រប់គ្រងក្រដាសផ្សេងៗបានទេ?

តើ ROI អ្វីដែលអ្នកផលិតអាចរំពឹង?

ឯកសារយោង សារ៉ាលីន។ ការវេចខ្ចប់ថ្ងៃនេះ របាយការណ៍និន្នាការឆ្នាំ 2024 ។ ArchDaily Insights ឆ្នាំ 2024 ។

វេជ្ជបណ្ឌិត Emily Carter ។ ប្រសិទ្ធភាពសម្ភារៈក្នុងម៉ាស៊ីនបត់ និងវេចខ្ចប់។ MIT Materials Lab ឆ្នាំ 2023 ។

PMMI របាយការណ៍ឧស្សាហកម្មគ្រឿងម៉ាស៊ីនវេចខ្ចប់ឆ្នាំ 2024៖ កំណើន និងនិរន្តរភាព។ PMMI Media Group ឆ្នាំ 2024 ។

EPA ការវេចខ្ចប់កាកសំណល់ និងការកែច្នៃឡើងវិញ ស្ថិតិឆ្នាំ 2024 ។ ទីភ្នាក់ងារការពារបរិស្ថានសហរដ្ឋអាមេរិក ឆ្នាំ 2024 ។

គណៈកម្មការសហភាពអឺរ៉ុប។ សារាចរណែនាំស្តីពីការគ្រប់គ្រងការវេចខ្ចប់ និងសេដ្ឋកិច្ចឆ្នាំ 2025 ។ ការិយាល័យបោះពុម្ពផ្សាយរបស់សហភាពអឺរ៉ុប ឆ្នាំ ២០២៥។

ទិនានុប្បវត្តិនៃផលិតកម្មប្រកបដោយនិរន្តរភាព។ ស្វ័យប្រវត្តិកម្មដែលមានប្រសិទ្ធភាពថាមពលនៅក្នុងឧបករណ៍វេចខ្ចប់ក្រដាស។ វ៉ុល។ 12, លេខ 2, 2024 ។

ការវេចខ្ចប់អឺរ៉ុប។ និន្នាការផលិតកម្ម និងការផ្លាស់ប្តូរសម្ភារៈបៃតង។ ការវេចខ្ចប់ ការពិនិត្យស្រាវជ្រាវអឺរ៉ុប ឆ្នាំ 2024 ។

Logistics Insight Asia។ ស្វ័យប្រវត្តិកម្ម និងម៉ាស៊ីនឆ្លាតវៃក្នុងការបំពេញតាម E-commerce ។ Logistics Insight Journal ឆ្នាំ 2023។

ការត្រួតពិនិត្យបច្ចេកវិទ្យាប្រកបដោយនិរន្តរភាព។ តួនាទីនៃប្រព័ន្ធ Servo ក្នុងប្រសិទ្ធភាពឧស្សាហកម្ម។ STR Global ឆ្នាំ 2023 ។

ក្រុមបច្ចេកទេសម៉ាស៊ីន Innopack ។ ក្រដាសសស្តីពីវិស្វកម្មម៉ាស៊ីនបត់ និងការគ្រប់គ្រងដំណើរការ។ របាយការណ៍ឧស្សាហកម្ម Innopack ឆ្នាំ 2025 ។

នៅឆ្នាំ 2025 បច្ចេកវិទ្យា Folding Machine ឈរជាគោលសម្រាប់ការផ្លាស់ប្តូរឧស្សាហកម្មឆ្លាតវៃ។ អ្នកជំនាញយល់ស្របថា ការរួមបញ្ចូលគ្នានៃវិស្វកម្មភាពជាក់លាក់ ប្រសិទ្ធភាពថាមពល និងការសម្របខ្លួនតាមឌីជីថល ធ្វើឱ្យវាក្លាយជាបេះដូងនៃផលិតកម្មប្រកបដោយនិរន្តរភាព។ ដូចដែលបណ្ឌិត Emily Carter (MIT) សង្កេតថា "ប្រព័ន្ធបត់ជំនាន់ថ្មីមិនគ្រាន់តែអំពីល្បឿនប៉ុណ្ណោះទេ វាគឺជាការឆ្លាតវៃ។ ឥឡូវនេះ ម៉ាស៊ីនរៀនពីទិន្នន័យ សម្របខ្លួនទៅនឹងវត្ថុធាតុដើម និងការពារកាកសំណល់មុនពេលវាកើតឡើង។"

ដូចគ្នានេះដែរ Sarah Lin (Packaging Today) សង្កត់ធ្ងន់ថា តម្រូវការសកលសម្រាប់ដំណោះស្រាយវេចខ្ចប់ក្រដាសកំពុងជំរុញឧស្សាហកម្មឆ្ពោះទៅរកម៉ាស៊ីនដែលរួមបញ្ចូលគ្នានូវទិន្នផលខ្ពស់ជាមួយនឹងការទទួលខុសត្រូវផ្នែកបរិស្ថាន។

សម្រាប់អាជីវកម្មដែលមានគោលបំណងធ្វើឱ្យមានតុល្យភាពនៃប្រាក់ចំណេញជាមួយនឹងការអនុលោមតាម ការធ្វើឱ្យប្រសើរទៅម៉ាស៊ីនបត់កម្រិតខ្ពស់មិនគ្រាន់តែជាការទិញនោះទេ វាគឺជាការវិនិយោគលើភាពធន់។

នៅក្នុងយុគសម័យនៃនិរន្តរភាព និងស្វ័យប្រវត្តិកម្ម ម៉ាស៊ីនបត់ជានិមិត្តរូបនៃការវិវត្តន៍នៃភាពវៃឆ្លាតឧស្សាហកម្ម—ម៉ាស៊ីនដែលបត់មិនត្រឹមតែក្រដាសប៉ុណ្ណោះទេ ប៉ុន្តែគម្លាតរវាងប្រសិទ្ធភាព និងបរិស្ថានវិទ្យា។