Hlola izinto ezintsha zakamuva zomshini Wokwenza Amabhamuza Omoya we-Innopack - okuhlanganisa ubunjiniyela be-resin obuqhubekayo, ukunemba kwe-extrusion, kanye nezinhlelo ze-QC ezixhumene nomugqa ukuze ulethe izixazululo zokupakisha ezisebenza kahle, ezivumelana nemvelo ezithenjwa izinto zomhlaba wonke kanye nemikhiqizo ye-e-commerce.

Isifinyezo Esisheshayo (Konjiniyela Bokupakisha Nabaphathi Bokusimama)Uma ulayini wakho wokupakisha usancike kufilimu yendabuko yomqamelo, yisikhathi sokucabanga kabusha.

Lo mhlahlandlela uveza ukuthi i-Innopack Machinery iyichaza kanjani kabusha Imishini Yokwenza Amabhamuza Omoya ngokusungula izinto ezintsha, ezishintshayo, kanye nesibopho sendawo ezungezile — iqinisekisa ukuthi imitha ngayinye yefilimu oyikhiqizayo iyasebenza, iyasebenziseka kabusha, futhi iyahambisana nezinqubomgomo ze-EPR zomhlaba jikelele.

Kusukela ekuhlanganisweni kwe-resin kuya ekuhlanganisweni kwe-roll, idizayini ye-Innopack ye-modular kanye nokuhamba komsebenzi okusemgqeni we-QC kuletha ukusebenza, ukunemba, nokuthula kwengqondo.

Yini Eyenza Imishini Yokwenza Amabhamuza Omoya Ithuthuke Kangaka

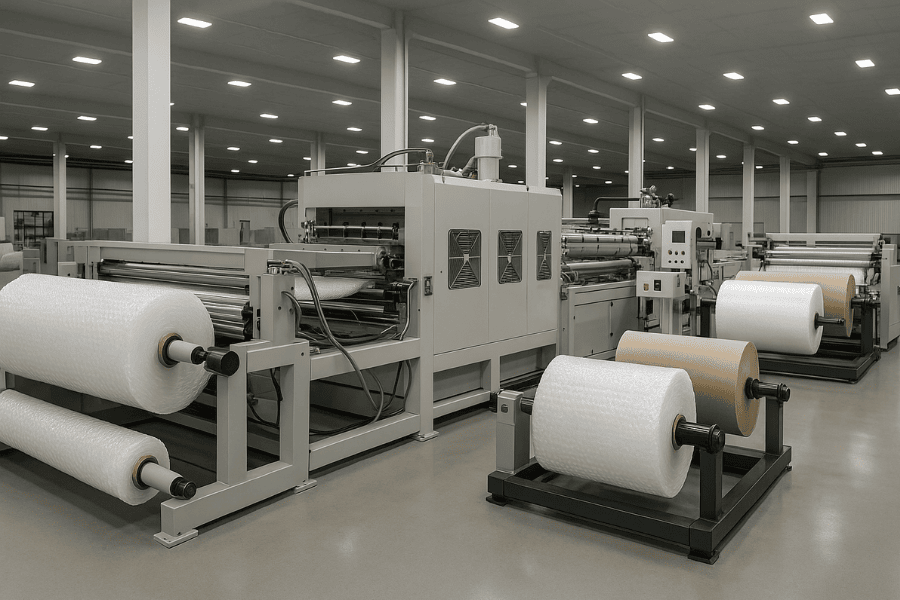

Umshini Wokwenza Amabhamuza Omoya

Ubunjiniyela Bezinto ezibonakalayo kanye Nokwakhiwa Kwemishini

Ibhalwe nguLeo Zhang | Unjiniyela Omkhulu Wezinqubo, Imishini ye-Innopack

-

I-Eco-PE Resin Blends: Ihlanganisa i-PE egaywe kabusha nesekelwe ku-bio ngaphandle kokubeka engcupheni amandla aqinile.

-

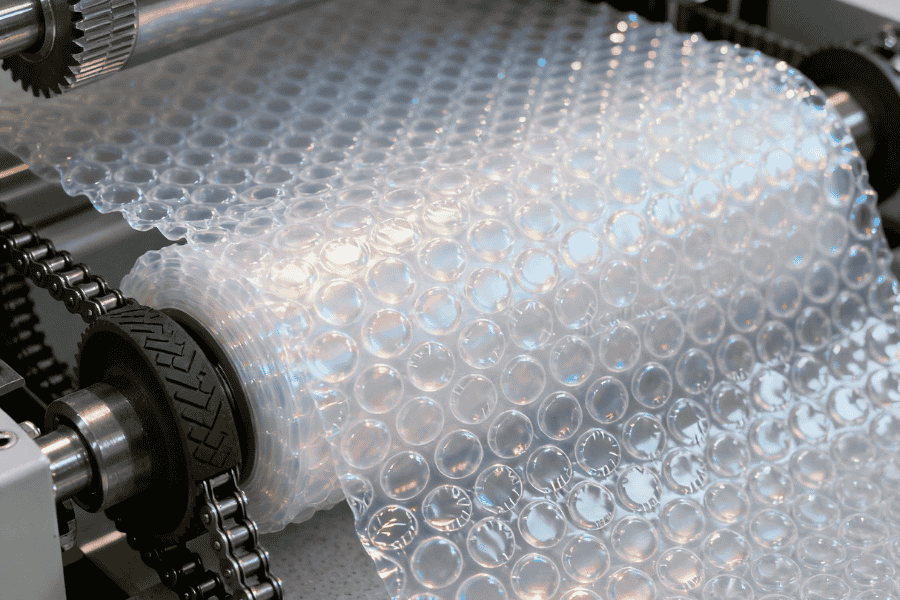

Idizayini ye-Bubble Mold enembile: Iqinisekisa amaseli omoya alinganayo, igeji elizinzile, kanye nesilinganiso esincishisiwe sokuvuza.

-

I-PID Heating & Multi-Zone Control: Igcina ibhalansi ye-extrusion ephelele kanye nokwehla kwamandla emali amabhamuza okungaguquki.

Umklamo oyinhloko uhlanganisa i-extrusion eyonga ugesi, ukwenziwa ngcono kwefilimu, futhi impendulo yokuqina okusemgqeni, okuholela esilinganisweni Ukunciphisa ngo-18% kudoti ye-resin ngethani lefilimu elikhiqizwayo.

I-Bubble film microstructure nemininingwane yomshini

Kungani Amabhrendi Ahamba Phambili Akhetha Amasistimu we-Innopack

-

Ilungiselelwe ukupakishwa okuphezulu kwe-e-commerce kanye nokusebenza okungu-24/7.

-

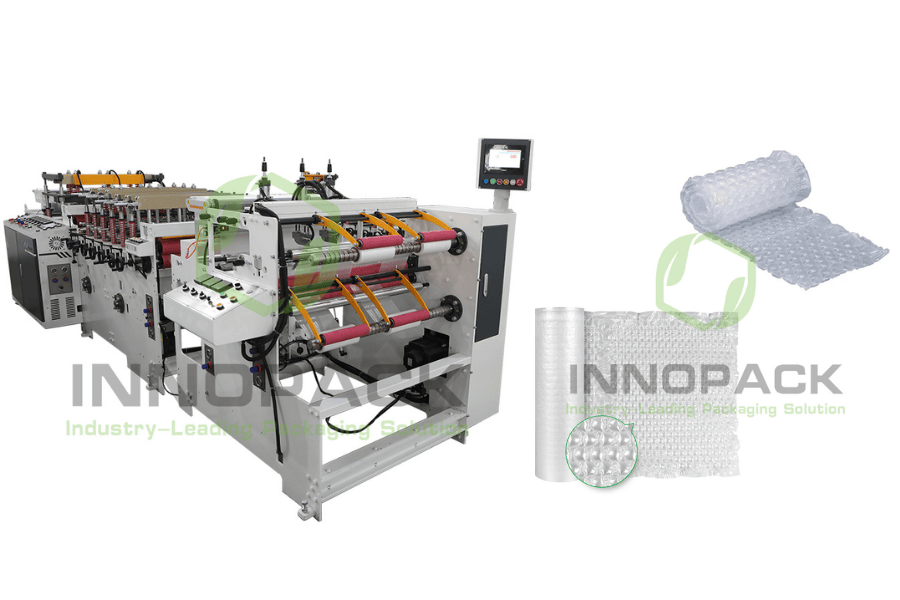

Ukupholisa okuhlanganisiwe, ukusonga, nokusika amamojula anciphisa ukuphatha ngesandla.

-

Amalogi okukhiqiza alungele idatha ngokubika kwe-EPR kanye nokulandelelwa kwe-supply chain.

Kusukela ekuqaleni ukuya kuma-logistics hubs, i-Innopack's Imishini Yokwenza Amabhamuza Omoya thuthukisa i-OEE (Ukusebenza Ngokuphelele Kwezisetshenziswa) kuze kufike ku-23% uma kuqhathaniswa nama-extruder amafilimu ayifa.

Umshini Wokwenza Amabhamuza Omoya Osezingeni eliphezulu

Ukusuka ku-Pellet kuya Ekuvikelweni - Ukuhamba komsebenzi kwe-Innopack

Isinyathelo 1 - Ukulungiswa Kwe-resin

Isinyathelo sesi-2 - Ukukhishwa Kwefilimu Nokwakhiwa Kwebhamuza

Isinyathelo sesi-3 - Ukupholisa nokubuyisela emuva

Isinyathelo sesi-4 — Amasango e-QC asemgqeni (CR / MA / MI)

-

I-CR (Ukubuyekezwa Kokulinganisa): Ukufana okushisayo nokuhlola iphrofayela yegeji.

-

MA (Ukuhlolwa Okubalulekile): Imephu yokucindezela kwebhamuza nokuhlolwa kokuvuza kwe-seal.

-

I-MI (Ukuhlolwa Komshini): Ukuminyana kweroll, ubuqotho obuyinhloko, nokuqinisekiswa kwephakheji.

Isinyathelo sesi-5 - Ukuklama nokulebula

Izicelo Zokuklama kanye Nomphumela Wemboni

Ukugcwaliseka kwe-E-commerce - Vikela izimpahla ezintekenteke ngobubanzi obunwetshiwe bomqulu namandla ophawu.

Ukukhiqiza Kwezogesi - Izinketho zefilimu ye-Anti-static yamabhodi wesekethe namamojula anembile.

Ukunakekelwa kwezempilo ne-Pharma - Ifilimu ehlanzekile yezinga le-ISO yokuthunyelwa okuyinyumba nokuzwela ukushisa.

Isitolo se-E-commerce sisebenzisa ama-bubble film rolls

Ukwenza ngokwezifiso kwe-OEM & Ukuhlanganiswa ngu-Innopack

-

Ububanzi beroli ngokwezifiso nejometri yebhamuza (8–40 mm) ngezidingo ezahlukene zokupakisha.

-

Ukuhlanganiswa kokulawula okuhlakaniphile nge-ERP, MES, kanye nezinhlelo ze-WMS.

-

Imephu enesici esizenzakalelayo futhi izexwayiso zokulungisa ezisekelwe emafini.

-

Uhlelo Lokulandeleka - Imiqulu enekhodi ye-QR exhunywe ku-resin batch kanye nendawo yokukhiqiza.

Khipha Ukupakishwa kanye Nenqubo Yokuqinisekisa Ikhwalithi

Ubunjiniyela Bekhreyithi

I-VGM & Label Traceability

Ukulawula Umswakama

Ukusimama kanye Nobuholi Bomnotho Oyindilinga

Ukutholwa Okunesibopho

Wonke ama-resin atholakala kubahlinzeki be-PE abaqinisekisiwe nabahlinzeki be-PE abavuselelekayo.

I-Low-VOC Processing

Ukukhishwa kwefume & degassing resin kunciphisa ukungcola ngo-21%.

I-Circular Logistics

Amasistimu awumongo abuyiswayo kanye nezinhlelo zefilimu ezibuyisela emuva zinciphisa ingqikithi yemfucuza ngo-28%.

Umshini Wokwenza Ibhamuza Lomoya Wepulasitiki

Ulwazi Lochwepheshe

Umbono Wonjiniyela Wenqubo

"Amandla e-seal afanayo kanye negeji yefilimu ezinzile akuzona inhlanhla - ziwubunjiniyela obunembayo."

— U-Leo Zhang, Unjiniyela Omkhulu Wezinqubo, Imishini ye-Innopack

Impendulo Yeklayenti

"Imishini iletha okukhiphayo okungaguquki ngokushintsha kwefilimu eyi-zero ngesikhathi sokugijima ngesivinini esikhulu."

— Inhloko Yokuthenga, I-Global E-commerce Operator

Quality Control Insight

"Ukuvuza kwethu okuxhumene nemephu kwehlise amanani ezicelo kusukela ku-2.8% kuya ku-0.6% ngaphansi kwezinyanga ezintathu."

— Umqondisi we-QC, I-Innopack Ifekthri

imibuzo ejwayelekile ukubuzwa

Q1: Iyiphi ingxube ye-resin eyenza kahle kakhulu kumafilimu amabhamuza omoya?

I-PE egaywe kabusha (40–60%) ene-LDPE emsulwa kanye ne-anti-block masterbatch inikeza ibhalansi efanelekile.

Q2: Ingabe uhlelo lungakwazi ukusebenzisa izingxube ezingaboli?

Yebo - i-hybrid die isekela i-PLA, i-PBAT, noma i-bio-PE kufika ku-35%.

Q3: Kufanele kwenziwe kangaki ukulinganisa kwe-QC?

Njalo emahoreni angama-72 noma ngemuva kokushintshwa kwe-resin.

Q4: Iyini isilinganiso esiphumayo ngomugqa ngamunye?

Phakathi kuka-120-180 kg/ihora kuye ngosayizi webhamuza nobubanzi befilimu.

Q5: Ungakuqinisekisa kanjani ukupakishwa ngaphambi kokuthekelisa?

Hlola i-QR roll ID, ilebula ye-VGM, nesibonisi somswakama ngaphakathi kwekhreyithi.

Kungani Indlela Ye-Innopack Isebenza

U-Innopack uyaphenduka ifilimu extrusion ibe ukusimama okuqhutshwa idatha.

Ngamunye Umshini Wokwenza Amabhamuza Omoya yakhelwe njengeluphu yempendulo evaliwe — i-resin → ibhamuza → QC → ikhreyithi → ukulandeleka — iqinisekisa ukuvikeleka okungaguquki, ukuvuza okumbalwa, kanye ne-carbon footprint ephansi.

Umshini Wokwenza Amabhamuza Omoya Wepulasitiki

Bizela Esenzweni

Izithenjwa

-

I-ASTM D3575 — Izindlela Zokuhlola Ezijwayelekile Zezinto Zeselula Ezivumelanayo

-

I-ISO 11607 - Ukupakishwa kwamadivayisi ezokwelapha abulawe inzalo

-

I-EPR Compliance Manual, EU 2025 Directive

-

I-Innopack Machinery Technical Handbook Rev.2025

-

I-Global Packaging Journal — “Amathrendi Okukhiqizwa Kwefilimu Eyindilinga 2025”

Njengoba ukusimama kokupakisha kusuka esithembisweni kuya ekusebenzeni, Imishini ye-Innopack iphambili ekwenziweni okusha - ichaza kabusha ukuthi ifilimu yebhamuza lomoya ikhiqizwa, ihlolwe, futhi ilethwe kanjani. Nge-extrusion ethuthukisiwe, ukuvala uphawu okuhlakaniphile, kanye nokulandeleka kweluphu evaliwe, le mishini isika udoti ngenkathi ikhulisa ukwethembeka.

Njengoba ukusimama kokupakishwa kusuka esithembisweni kuya ekusebenzeni, i-Innopack Machinery imi phambili ekusungulweni okusha - ichaza kabusha ukuthi ifilimu yebhamuza lomoya ikhiqizwa, ihlolwe, futhi ilethwe kanjani. Nge-extrusion ethuthukisiwe, ukuvala uphawu okuhlakaniphile, kanye nokulandeleka kweluphu evaliwe, le mishini isika udoti ngenkathi ikhulisa ukwethembeka.

"Asisaboni i-extrusion yefilimu njengenqubo, kodwa njenge-ecosystem exhunyiwe - ukusuka ku-resin kuya ekusetshenzisweni kabusha,"

kusho u-Leo Zhang, onguNjiniyela Omkhulu Wezinqubo kwa-Innopack Machinery.

"Ukuhlanganiswa kokulawula okuhlakaniphile kanye nokuhlaziya kwesikhathi sangempela kusiza amakhasimende ethu ukufeza kokubili izinhloso zokusebenza kwezomnotho nezemvelo."

Emhlabeni ofuna izixazululo eziyindilinga, Imishini Yokwenza Amabhamuza Omoya ka-Innopack ihlanganisa isizukulwane esilandelayo sokukhiqiza okuzinzile kokupakisha - okunembayo, okuqhutshwa yidatha, nokuthobela umhlaba wonke.