Hlola izinzuzo eziphezulu ezingu-5 zemishini yokupakisha yepulasitiki—ukusebenza okuphezulu, izinsalela eziphansi, ikhwalithi engashintshi, imisebenzi ephephile, nedatha elungele ukuhlolwa. Funda ukuthi i-automation ishayela kanjani i-ROI nokusebenza kokupakisha okuzinzile.

Isifinyezo Esisheshayo:Le ndatshana igqamisa izinzuzo ezinhlanu ezibalulekile zemishini yokupakisha yepulasitiki okufanele wonke umkhiqizi kanye no-opharetha wempahla kufanele azazi. Ngokwamukela izinhlelo zesimanje ezishintshayo, amabhizinisi angakwazi ukuzuza ukukhiqiza okuphezulu, ukumosheka kwezinto ezibonakalayo okuncishisiwe, ikhwalithi yokuvala engaguquki, ukuphepha okuthuthukisiwe komsebenzisi, kanye nokulandeleka okulungele ukuhlolwa. Isekelwe imininingwane yochwepheshe, izifundo zezenzakalo zomhlaba wangempela, nedatha yesayensi, ingxoxo ichaza ukuthi imishini yokupakisha iletha kanjani i-ROI elinganisekayo, imisebenzi eqhubekayo, kanye nokuncintisana kwesikhathi eside kumaketanga okunikezela emhlabeni jikelele.

Ivula Ingxoxo

Umphathi we-Ops (Emma): “Uma sishintsha ulayini wethu wokupakisha wepulasitiki, yiziphi izinguquko kuqala—izindleko, ikhwalithi, noma isivinini?”

Unjiniyela Wezinqubo (Liam): "Zontathu. Amasistimu esimanjemanje aqhutshwa yi-servo-fill-seal kanye nomcamelo womoya aphakamisa i-OEE, asike izinsalela, futhi azinzise ubuqotho bophawu."

Umholi Wezezimali (uNowa): “Nginike iwindi lokukhokha.”

U-Liam: "Ngokujwayelekile izinyanga ezingu-9-18, kuye ngokukhubazeka kwamanje, ukwakheka kwabasebenzi, nokusetshenziswa kwezinto ezibonakalayo. Ake ngikubonise izinombolo nobufakazi."

Abahlinzeki Bemishini Yokupakisha Yepulasitiki

Kungani Lesi sihloko Sibalulekile Manje

Ukuhweba komhlaba wonke kucindezela izikhathi zokulethwa ngenkathi kukhuphula ikhwalithi nemigoqo yokuthobelana. Okwabakhiqizi, amafemu wempahla, kanye nama-3PLs, imishini yokupakisha epulasitiki akuseyona "intokozo yokuba nayo" kodwa ingumgogodla wokugcwalisa ngesikhathi, okungenakonakala, nokuyongayo. Uma kucaciswe futhi kwenziwa ngendlela efanele, kwenyusa inani lempahla, kuthuthukise ukwaneliseka kwekhasimende, futhi kunwebe umkhawulo—ngaphandle kokwengeza inani elikhulu.

Izinzuzo Eziphezulu Ezi-5 (ezinomthelela womhlaba wangempela)

Ukusebenza Okuphakeme Ne-OEE (Ukusebenza Sezisetshenziswa Sekukonke)

Imigqa yesimanje iyasetshenziswa ukunyakaza kwe-servo, isilawuli sewebhu esihlakaniphile, nezinsimbi zokuvala zokulungisa ngokuzenzakalela ukuze kugcinwe isivinini ngokuma okumbalwa.

Umthelela ojwayelekile: +10–35% ukuthuthukiswa kokusebenza, +5–15% Izinzuzo ze-OEE.

Imbangela eyinhloko: ukushintshashintsha okusheshayo, izitobhi ezincane ezimbalwa, kanye nezinga lokushisa elivaliwe/ukulawula ingcindezi yokuvala.

Ivela kanjani ku-P&L yakho: Amayunithi amaningi athengisekayo ngeshifu ngayinye enabasebenzi abafanayo.

Udoti Wezinto Eziphansi Nezindleko Zeyunithi

Ukuqaqa okunembayo, umhlahlandlela onqenqemeni, nobude bokusika obukhiywe iresiphi kunciphisa ukunquma nokumbondela.

Umthelela ojwayelekile: -8–20% ukusetshenziswa kwefilimu ngeyunithi ngayinye; kuncishiswe ukusebenza kabusha.

Umkhayi wokuzinza: i-scrap encane ilingana nezindleko zokulahla eziphansi kanye nokubika okungcono kwe-ESG.

Umphumela we-P&L: Ngokushesha Ukwehliswa kwe-COGS kanye nohlu lwamafilimu, amalayini, nezikhwama.

Ikhwalithi Engaguquguquki Nokukhubazeka Okumbalwa

Amaphrofayili okuvalwa okuzinzile, ukuhlolwa kokuvuza okusemgqeni, kanye nokuhlolwa kwekhamera kunqamule amanani amaphutha.

Umthelela ojwayelekile: -30-60% amaphutha abonakalayo amakhasimende (izinyembezi, izimpawu ezibuthakathaka, ukuphrinta okungalungile).

Ibhonasi: Izimbuyiselo/izinkokhelo ezimbalwa ezimbalwa; amakhadi amaphuzu omthengisi/nomthengisi aqinile.

Umphumela we-P&L: Ukuchayeka kwewaranti encane nama-oda aphindayo aphezulu.

Ngokuphephile, Ukusetshenziswa Kwezabasebenzi Okuncane

Ukugada ezinkambisweni ze-ISO/CE, ukucutshungulwa okuzenzakalelayo, nokusetha okususelwe kumaresiphi kunciphisa izinyathelo eziyingozi ezenziwa ngesandla.

Umthelela ojwayelekile: -10–25% umsebenzi oqondile emgqeni; izigameko ezimbalwa ezirekhodwa nge-OSHA.

Umthelela wakwa-HR: Gcina opharetha abanamakhono ukuze benze imisebenzi enenani eliphakeme (ukugcinwa kokuvikela, i-SPC).

Umphumela we-P&L: Izindleko zabasebenzi ukusebenza kahle kanye nesikhathi esiphansi esihlobene nokuphepha.

Ukulandeleka, Ukuthobela kanye Nedatha Yezinqumo

Ilogi yesimanje ye-HMIs/PLCs inqwaba, izinga lokushisa, ingcindezi, isikhathi sokuhlala, kanye nemilando yamaphutha yocwaningomabhuku.

Umthelela ojwayelekile: ngokushesha ukuhlaziywa kwembangela; ukucwaningwa kwamabhuku okubushelelezi kwe-FDA/ISO.

I-flywheel yedatha: iphakela ukuthuthukiswa okuqhubekayo (i-CPK, amadeshibhodi e-SPC) nokunakekelwa okubikezelwayo.

Umphumela we-P&L: Okumangazayo okumbalwa, ukukhishwa okuya emkhunjini ngokushesha, nokuma okuthembekile kokuthobela.

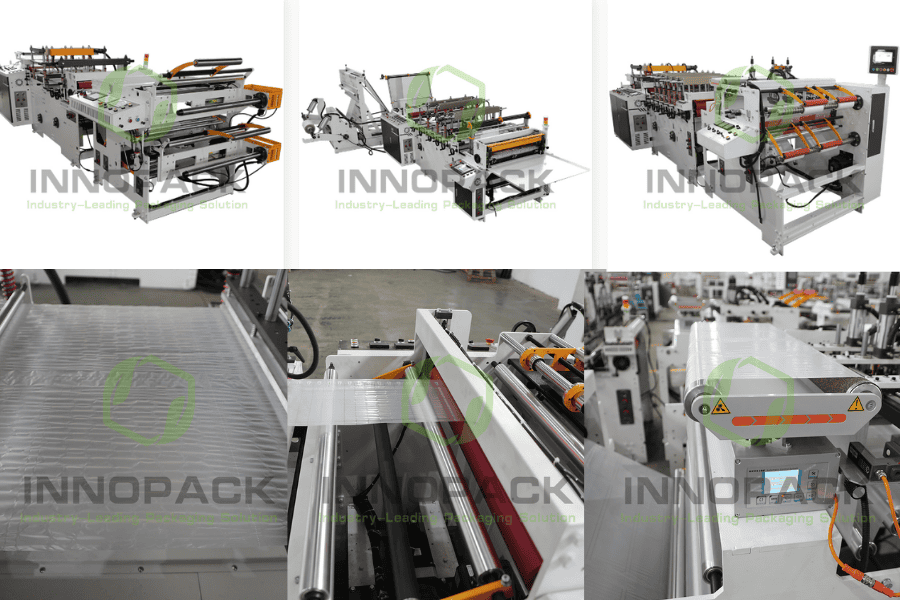

Kanjani Eyethu Kwakhiwe Imishini Yokufaka Ipulasitiki

Izinto zokwakha kanye nezingxenye ezibalulekile

Amafreyimu ensimbi engagqwali esezingeni lokudla (304/316): ukumelana nokugqwala nokusebenza kahle kwezindlu zangasese.

Amadrayivu e-servo anembe kakhulu + i-PID ye-loop evaliwe: ubude obuphindaphindayo bokusika kanye namaphrofayili ophawu.

I-Industrial PLC + 10–15” HMI: ukusetha okuqondisiwe, umtapo wolwazi weresiphi, ukukhiya opharetha.

Izinzwa ezihlakaniphile (ama-thermocouples, amaseli okulayisha, izifaki khodi): impendulo ebukhoma yophawu, ukushuba, nokuqondanisa kwewebhu.

Izifudumezi ezilungiselelwe amandla nokufakwa kwamafutha: ukushisa okusheshayo, ukulahlekelwa okulindile okuphansi.

Kungcono kunezakhiwo "ezijwayelekile": imishini yezimpahla ngokuvamile ihlanganisa amafreyimu ensimbi athambile, izilawuli ezivulekayo, nezilungiselelo ezenziwa ngesandla—okuholela ekukhukhuleni, ekulahlekeni, nasekuhlukeni komsebenzisi.

Inqubo Yokukhiqiza & QA

-

Ukwenziwa kwe-CNC & laser-cut → I-TIG/MIG yokushisela → ukukhululeka kokucindezeleka → ijazi powder noma passivation okwenhlanzeko.

-

Izitendi zokuhlola ze-sub-assembly (ukushayela, ukushisa, i-pneumatics) ngaphambi kokuhlanganiswa okugcwele.

-

I-FAT/SAT ephelele ngamafilimu akho nama-SKU; siyaqopha amajika ophawu futhi ukuzinza komjikelezo.

-

Amadokhumenti nokuqeqeshwa amaphakheji (ama-SOP, izinhla zokuhlola ze-PM, amakhithi ayisipele) ukuze akhiye ekusebenzeni.

Umphumela: ukunemba okuphindaphindwayo, ukugunyazwa okufushane, kanye nejika lokufunda leqembu lakho elikhuphukayo.

Ithebula Lokuqhathanisa Ngokushesha — Imanuwali/Semi-Auto vs. Imigqa Yesimanje

| Imibandela | Imanuwali / Semi-Auto | Okwesimanje Imishini Yokupakisha Yepulasitiki |

| Okokusebenza | 8–20 amaphakethe/min | 25–120+ amaphakethe/min (incike kwifomethi) |

| Isilinganiso Sesici | 1.5–4.0% | 0.3–1.2% |

| Ukushintsha | 30–90 imiz | 8–25 min (isizwa ngeresiphi) |

| I-Scrap / Overwrap | Okuphezulu, okuguquguqukayo | -8-20% iyunithi ngayinye |

| Ukulandeleka | Okuncane | Amalogi edijithali agcwele (HMI/PLC) |

| Ukuphepha | Incike ku-opharetha | Igadiwe ku-ISO/CE, izixhumanisi |

Ububanzi buyizinkomba; imiphumela incike ekuxubeni komkhiqizo, uhlobo lwefilimu, nokuvuthwa kokunakekelwa.

Izimo Zokusetshenziswa Komhlaba Wangempela Nempendulo Yabasebenzisi

Ikesi 1 — Isiphuzo esingu-3PL (EU)

-

Inkinga: ama-spikes evolumu yesizini adala isikhathi esengeziwe kanye namaphutha kuma-seams abuthakathaka.

-

Isenzo: kufakwe ulayini we-servo FFS one-auto tension control.

-

Umphumela (izinyanga ezingu-6): + 28%., -42% amaphutha, -12% ukusetshenziswa kwefilimu.

-

Impendulo yomsebenzisi: "Izinkinga ze-seal zinyamalale. Ushintsho ekugcineni luyabikezelwa."

Ikesi 2 — Cosmetics SME (US)

-

Inkinga: ilebula i-skew kanye nesikhwama esiqhuma endleleni yokuhamba.

-

Isenzo: Umbono ohlanganisiwe womugqa + ukuhlolwa kokuvuza; amafasitela ephrofayili yophawu aqinisiwe.

-

Umphumela: ukubuyisela emuva komthengisi kunqanyuliwe 60%; iyunithi yehle 9%.

-

Impendulo: "Ukungena kwedatha kusisiza ukuthi siwine ukucwaninga ngemizuzu."

Ikesi 3 — Izingxenye Zogesi (VN)

-

Inkinga: Ukuhlukahluka kwephakheji okuzwela kwe-ESD.

-

Isenzo: amafilimu e-antistatic akhiywe ngeresiphi + ukungezwani kwewebhu okunembile.

-

Umphumela: -35% izinsalela zezinto; +15% OEE.

-

Impendulo: "Abasebenzi bayayithanda i-HMI eqondisiwe-akusekho ukuqagela."

Funda kabanzi mayelana nezixazululo nezicelo zethu:

– Imishini Nokusebenza

– Izinsiza

– Xhumana nathi

Imishini Yokupakisha Yepulasitiki

I-Expert Insights & Industry Trendlines

-

I-Automation ROI windows amaphakheji ahlale 9-24 izinyanga kuzilungiselelo eziningi ze-SMB/zebhizinisi lapho imfucuza nomsebenzi kuyizindleko zempahla.

-

Ukufakwa kukagesi (i-servo vs. pneumatics) yehlisa ukusetshenziswa kwamandla ngephekhi ngalinye futhi ilola ukuphindaphinda.

-

Ama-ops wokupakisha wedatha yokuqala sekuba yinjwayelo: ukuphathwa kweresiphi, i-QC ekumugqa, namadeshibhodi e-SPC manje ashayela ukubuyekezwa kobuholi kwansuku zonke.

Imithombo eyinkomba ihlanganisa ama-PMMI Isimo Sezimboni kanye nemibono yemakethe yakwaSmithers; bona Izithenjwa ukuze uthole imininingwane (ama-URL angachofozeki).

Okugqanyisiwe Kwedatha Yesayensi (Amabhentshimakhi ayizinkomba)

-

Ukuhlukahluka kwamandla e-Seal angawa 30–50% ngezinga lokushisa elivaliwe kanye nokulawula isikhathi sokuhlala, kunciphisa ukwehluleka kwenkambu.

-

Isivuno sezinto ezibonakalayo kuyathuthuka 8–20% ngobude obuqondile bokusika nomhlahlandlela onqenqemeni.

-

Ukuchayeka emsebenzini ukunyakaza okuphindaphindiwe kuyehla 15–30% nge-auto-threading kanye ne-motorized roll-lift systems.

-

Ukuqina kwamandla iyunithi ngayinye epakishiwe ingancipha 5–15% kuma-servo retrofits vs. legacy pneumatic cycles.

I-Implementation Playbook (Kusuka ku-spec kuya ekukhokheleni)

Isinyathelo 1: Isisekelo kanye Nendaba Yebhizinisi

Linganisa i-OEE, ukukhubazeka, izinga le-scrap, amandla, noshintsho namuhla.

Yakha imodeli enezinzuzo ezilandelanayo (isb., +12% throughput, –10% film).

Isinyathelo sesi-2: Ukucaciswa Kweqiniso, Hhayi Izincwajana

Khiya izinhlobo zefilimu, ububanzi, imininingwane yophawu, futhi Imvamisa yokushintshwa kwe-SKU.

Dinga FAT/SAT ku lakho izinto zokwakha.

Isinyathelo sesi-3: Ukugunyazwa nekhono

Gunyaza iwindi lokuvala izifundo kanye umbono/ukuvuza indlela yokwamukela.

Isitimela ngokumelene Ama-SOP futhi PM i-cadence.

Isinyathelo sesi-4: Gcina Izinzuzo Ngedatha

Buyekeza I-CPK/SPC masonto onke; vala izihibe ku-drift.

Sebenzisa idatha yelogi ukuthola izindlela zokuhlola kanye nokugcinwa kokuvikela.

Hlola imindeni yethu yezisetshenziswa kanye nezinketho ku Imishini ye-Innopack.

FAQ

Ithini i-ROI/inkokhelo ejwayelekile yemishini yokupakisha yepulasitiki?

Izitshalo eziningi zibona 9-18 izinyanga kuye ngokuthi izingcezu eziyisisekelo, imodeli yabasebenzi, kanye nevolumu. Izingosi ezinokukhubazeka okuphezulu/okulahlwayo zikhokha ngokushesha.

Ingabe umugqa owodwa ungaphatha amafilimu nosayizi abahlukene?

Yebo—imitapo yolwazi yokupheka, amasethi efomethi eshintsha ngokushesha, nokuqondisa okuzenzakalelayo kwewebhu kunika amandla imisebenzi ye-SKU/amafilimu amaningi. Qinisekisa nge-FAT nge-SKU ngayinye ebalulekile.

Ngiyigcina kanjani ikhwalithi ye-seal izinzile kuwo wonke amashifu?

Sebenzisa ukushisa/ingcindezi/indawo yokuhlala evaliwe, gcina izinzwa ezilinganiselwe, nokuhlola uphawu-iphrofayili izingodo masonto onke. Engeza ukuvuza okusemgqeni noma ukuhlola kokubona kwama-SKU abalulekile.

Iyiphi indawo yesondlo okufanele ngiyihlelele?

Ukuhlolwa kwansuku zonke nokuhlolwa; ukuhlolwa kwamasonto onke kwamabhande, imimese, nezifudumezi; ukulinganisa kwanyanga zonke; ngekota PM namakhithi ayisipele. Ngena zonke izenzo ku-HMI/CMMS.

Ulayini ukusekela kanjani ukuthobela (i-FDA/ISO/CE)?

Amarekhodi eqoqo ledijithali, imilando yama-alamu, nezindlela zokupheka ezilawulwayo zenza kube lula ukuhlola. Khetha izinto ezisezingeni lokudla futhi uqinisekise ukuhlolwa kobungozi (FMEA) zibhaliwe.

Izithenjwa

-

PMMI • Isimo Semboni - Imishini Yokupakisha 2024/2025 • PMMI • pmmi(dot)org

-

Smithers • Ikusasa Lokupakishwa Kwembulunga yonke lango-2029 • Smithers • smithers(dot)com

-

McKinsey & Company • Okuzenzakalelayo, amarobhothi, kanye nemboni yesikhathi esizayo • McKinsey • mckinsey(dot)com

-

I-ASTM International • Izimpawu Zokupakisha Okuguquguqukayo - Izindlela Zokuhlola • ASTM • astm(dot)org

-

ISO 14120/13849 • Ukuphepha kwezindinganiso zemishini • ISO • iso(dot)org

-

IEEE/ISA • I-Closed-Loop Control in Industrial Packaging • IEEE/ISA • ieee(dot)org / isa(dot)org

-

I-PwC • Imboni 4.0: Ukwakha ibhizinisi ledijithali—Ukupakisha • PwC • pwc(dot)com

-

NIST • I-Smart Manufacturing: Isayensi Yokulinganisa Yokupakisha • NIST • nist(dot)gov

-

BSI • Ukupakishwa kokudla-Iziqondiso Zokuklama Okuhlanzekile • BSI • bsigroup(dot)com

-

Ucwaningo lwe-Allied Market • Isibikezelo Semakethe Yokupakisha • I-Allied • alliedmarketresearch(dot)com

-

I-Rockwell Automation • Ukusebenzisa i-Servo Motion kumigqa yokupakisha • I-Rockwell • i-rockwellautomation(dot)com

-

I-SME • Ukunciphisa Imfucuza Emisebenzini Yokupakisha • SME • sme(dot)org

Imishini yokupakisha yepulasitiki imele ukuthuthukiswa okuwujuqu kwamabhizinisi afuna ukusebenza kahle, ukulawula izindleko, nokuthobela. Izinzuzo ezinhlanu ezibaluliwe—umphumela, ukuncishiswa kwemfucuza, ubuqotho bezimpawu, ukuphepha kwezisebenzi, kanye nokulandeleka—zihumusha ngokuqondile i-ROI elinganisekayo.Njengoba uDkt. Martin Keller, Unjiniyela Omkhulu Wokupakisha e-European Packaging Institute, ebonisa: “Ukuzenzakalela emaphaketheni epulasitiki akukhona ukufaka esikhundleni abantu, kumayelana nokushintshaniswa kweqoqo ngalinye.” Isitatimende sakhe sihambisana nezifundo zemboni eziqinisekisa ukuthi amasistimu azenzakalelayo anganciphisa amaphutha aze afike ku-60% futhi anciphise ukusetshenziswa kwezinto ezibonakalayo cishe ngama-20%. Ubufakazi busobala: izinkampani ezenza imisebenzi yazo yokupakisha ibe yesimanjemanje zivikela ukuqina kokuncintisana kanye nokusimama kwesikhathi eside.